Nanoformulation Batch Release Testing Services

Inquiry

As nanotechnology advances, nanoformulations unlock new possibilities in drug delivery systems, disease therapies, in vivo imaging, diagnostics, and more. Batch release testing is a critical quality checkpoint, directly influencing the performance and safety of nanoformulations. CD Formulation prioritizes quality control through rigorous batch release testing during commercial-scale production and post-market monitoring to meet diverse client needs.

Importance of Nanoformulation Batch Release Testing

Batch release testing is the process of ensuring the quality and safety of a nanoformulation before it is released into the market. It involves a series of tests and evaluations performed on a batch of nanoformulations to ensure that it meets the required standards and specifications. We control the quality of nanoformulations by testing the batch release of nanoformulations, which is helpful to ensure that nanoformulations meet expected quality requirements before clinical research, before commercial-scale production is approved, and during post-market production monitoring.

Our Comprehensive Nanoformulation Batch Release Testing

CD Formulation is committed to researching and developing nanoformulations to help global researchers promote the clinical transformation of nanoformulations. In accordance with the relevant requirements for batch release inspection of conventional dosage forms, we strictly conduct batch release inspection of the following indicators to ensure that the quality of the final product meets the standard requirements.

Characterization of Nanoformulations

The characterization of nanoformulations reflects the proprietary characteristics of nanoformulations. We mainly provide characterization testing services for indicators based on specific nanoformulations, such as particle size distribution, micromorphology, surface properties, Zeta potential, encapsulation efficiency, drug loading, etc.

Elemental Impurity Testing

We have established a nanoformulation elemental analysis platform that can select appropriate and robust elemental analysis methods based on the different dosage forms of nanoformulations to control elemental impurities in nanoformulations.

Residual Solvent Testing

Depending on the nanoformulation, we first evaluate and analyze the potential residual solvents and perform qualitative and quantitative analysis to ensure that the residual solvents meet the quality standard requirements of the nanoformulation.

In Vitro Drug Release Testing

In vitro drug release of nanoformulations is the external manifestation of the release of nanoformulations in the human body and is an intrinsic property of nanoformulations. We ensure the safety and effectiveness of clinical use of nanoformulations by testing in vitro drug release.

Our Workflow for Nanoformulation Batch Release Testing

Our structured process ensures precision at every step. We offer a tailored workflow, from initial characterization to final product evaluation. The typical steps include:

- Sample Receipt and Preparation

- Analytical Method Development and Validation

- Testing for Specific Indicators (e.g., particle size, zeta potential, impurities)

- Comprehensive Data Analysis

- Final Report Submission with Recommendations

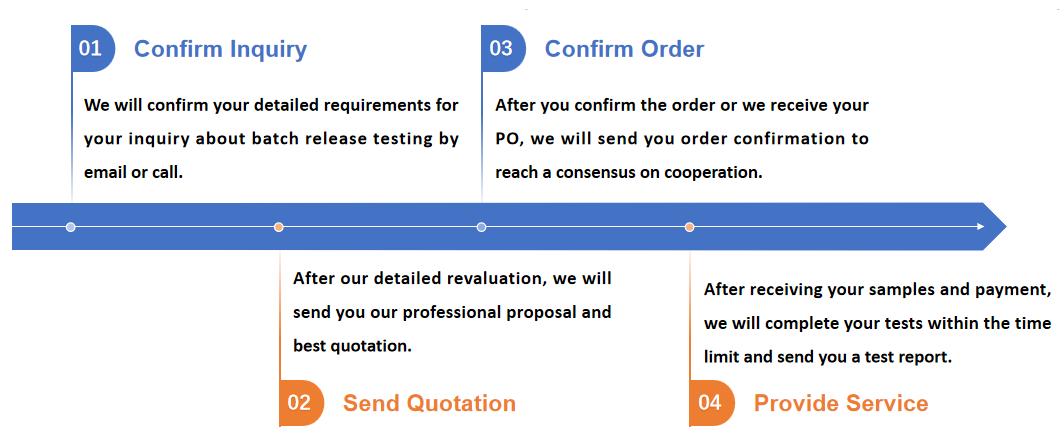

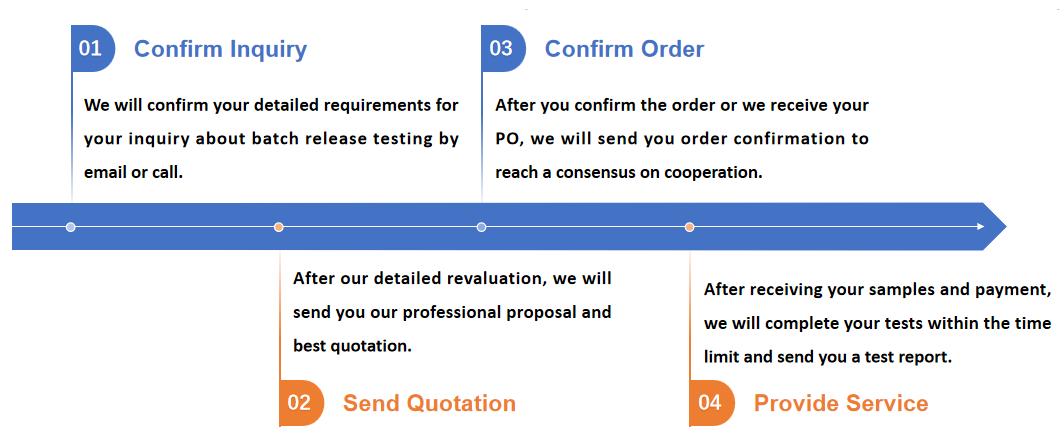

Fig.1 Our nanoformulation batch release testing ordering process. (CD Formulation)

Fig.1 Our nanoformulation batch release testing ordering process. (CD Formulation)

Our Nanoformulation Batch Release Testing Capabilities

- We have extensive experience in nanoformulation testing and regulatory compliance assessment, serving a variety of industries, including but not limited to pharmaceuticals, over-the-counter drugs, consumer health products, cosmetics, and other industries.

- Our experienced analytical team has extensive knowledge of validated nanoformulation quality assessment methods and regulatory stability requirements.

- We perform nanoformulation batch release testing according to USP pharmacopoeia methods and ICH guidelines, which provide guidance for nanoformulation quality analysis and stability of nanoformulations.

Custom Nanoformulation Batch Release Testing

CD Formulation has lots of experience in nanoformulation batch release testing, covering nanoproperty characterization (such as particle size distribution, Zeta potential, microscopic morphology, surface property, etc.), qulity control and testing for nanoformulation.

| Items |

Specific Analytical Services |

| Characterization of Nanoformulations |

Nanoformulation Mean Particle Size Distribution and Testing Service

We have advanced equipment for nanoformulation mean particle size distribution. It can provide customers with nanoformulation mean particle size distribution and testing services to ensure the particle size distribution meets the requirements for nanoformulations. |

Zeta Potential Measurement Service for Nanoformulations

With the support of our zeta potential analyzer, we have lots of experience in the zeta potential measurement process. We can offer zeta potential measurement services for nanoformulations utilizing different techniques, such as electrophoresis, electro-osmosis, streaming potential, or sedimentation potential method. |

Microscopic Morphology Testing of Nanoparticles

CD Formulation can provide clients with microscopic morphology testing of nanoparticles, using some suitable techniques, including brunauer-emmett-teller (BET) technique, transmission electron microscope (TEM), scanning electron microscopy (SEM), atomic force microscope (AFM), etc. |

Nanoformulation Surface Property Testing Service

With our state-of-the-art analytical equipment, we can offer nanoformulation surface property testing services including surface charge testing, surface structure analysis, characteristics of the degree of PEGylation on the surface of the nanoparticles, and the elemental composition. |

Nanoformulation Encapsulation Efficiency Testing Service

Our technical team has rich experience in nanoformulation encapsulation efficiency testing utilizing chromatography, NMR, fluorescence spectrophotometer, etc. We can offer our professional nanoformulation encapsulation efficiency testing service to aid the nanoformulation development. |

Nanoformulation Drug Loading Testing Service

We have established direct and indirect methods based on the measurement of drug loading in nanoformulations and can provide our customers with nanoformulation drug loading testing services to meet the quality standard of nanoformulations. |

| Quality Control and Testing for Nanoformulations |

Nanoparticle Concentration Testing Service

CD Formulation has multiple nanoparticle concentration analyzers based on optical principles and electrical principles. We can offer nanoparticle concentration testing services to meet customers' personalized requirements for batch release standards. |

Nanoformulation Critical Micelle Concentration Testing Service

Our core team has advanced design concepts for nanoformulation critical micelle concentration testing and can provide our professional CMC testing services for nanoformulations. |

Nanoformulation Critical Aggregation Concentration Testing Service

CD Formulation has explored and developed critical aggregation concentration testing techniques including static light scattering (SLS), dynamic light scattering (DLS), tensiometric, conductometric, fluorometric, and calorimetric methods. And we can offer CAC testing for nanoformulations to meet the quality standard of batch release. |

Nanoformulation Elemental Impurity Testing Service

We are good at performing nanoformulation elemental impurity testing according to the ICH Q3D guideline and can offer our novel design concept and professional elemental impurity testing services for nanoformulations. |

Nanoformulation Residual Solvent Testing Service

Supported by our state-of-the-art device testing facilities, we can offer nanoformulation residual solvent testing service to ensure the residual solvents meet the quality standard of nanoformulations. |

In Vitro Release Determination of Nanoformulations

We have developed multiple in vitro release determination methods for nanoformulations, such as sample and separate, membrane-free dissolution, continuous flow, dialysis assay, etc. And we can provide our professional proposal and testing service to meet the standard of batch release. |

Endotoxin and Sterility Testing Service of Injectable Nanoformulations

CD Formulation has also been committed to providing endotoxin and sterility testing services for injectable nanoformulations to meet the quality standard of batch release. |

Due to their characteristics and special preparation requirements, nanoformulations require batch release testing of the final product to confirm that the quality of each batch produced meets the quality standards to ensure the effectiveness and safety of clinical medication. CD Formulation can offer nanoformulation batch release testing services to meet the quality standard of nanoformulations. If you are interested in our nanoformulation batch release testing service, please kindly contact us.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 Our nanoformulation batch release testing ordering process. (CD Formulation)

Fig.1 Our nanoformulation batch release testing ordering process. (CD Formulation)