Nanomedicine - CD Formulation

Call Us:

- Home

- Services

- Nanoformulation Development

- Nanoparticle Development for Nanomedicine

- Solid Lipid Nanoparticle Development for Nanomedicine

- Albumin Nanoparticle Development for Nanomedicine

- Lipid Nanoparticle Development for Nanomedicine

- Polymeric Nanoparticle Development for Nanomedicine

- Biomimetic Nanoparticle Development for Nanomedicine

- Environmentally Responsive Nanoparticle Development for Nanomedicine

- Nanosuspension Development for Nanomedicine

- Liposome Development for Nanomedicine

- Exosome Development for Nanomedicine

- Nanostructured Lipid Carrier Development for Nanomedicine

- Nanoemulsion Development for Nanomedicine

- Nanocrystal Development for Nanomedicine

- Polymeric Micelle Development for Nanomedicine

- Nanofiber Development for Nanomedicine

- Nanocapsule Development for Nanomedicine

- Nanogel Development for Nanomedicine

- Microparticle Development for Nanomedicine

- Targeting Nanoformulation Development

- Generic Nanoformulation Development

- Oral Nanoformulation Development

- Nanoparticle Development for Nanomedicine

- Nanoformulation Analysis

- Characterization of APIs and Nanocarriers

- Nanoformulation Mean Particle Size Distribution and Testing Service

- Zeta Potential Measurement Service for Nanoformulations

- Nanostructure Characteristics Analytical Service

- Crystallinity Testing Service for Nanoformulations

- Microscopic Morphology Testing of Nanoparticles

- Nanoformulation Surface Property Testing Service

- Nanoformulation Molecular Weight Distribution Testing Service

- Nanoformulation Encapsulation Efficiency Testing Service

- Nanoformulation Drug Loading Testing Service

- Nanoparticle Concentration Testing Service

- Drug Release Testing Service for Nanocarriers

- Nanoformulation Thermal Performance Analysis

- Nanoformulation Critical Micelle Concentration Testing Service

- Nanoformulation Critical Aggregation Concentration Testing Service

- Nanoformulation Elemental Impurity Testing Service

- Nanoformulation Stability Testing Service

- Nanoformulation Residual Solvent Testing Service

- In Vitro Release Determination of Nanoformulations

- Endotoxin and Sterility Testing Service of Injectable Nanoformulations

- Nanoformulation Analytical Method Development and Optimization

- Nanoformulation Analytical Method Validation and Transfer

- Nanoformulation Biological Evaluation

- Nanoformulation Batch Release Testing Services

- Nanoformulation Pilot Scale-up Services

- Nanoformulation Development

- Technologies

- Nanotechnology Platforms for Nanoformulations

- Nanotechnology for Drug Delivery

- Targeting Drug Delivery System for Nanoformulations

- Microparticle Drug Delivery System for Nanoformulations

- Colloidal Drug Delivery System for Nanoformulations

- Self-emulsifying Drug Delivery System for Nanoformulations

- Exosome Drug Delivery System for Nanoformulations

- In Vivo Drug Delivery Strategies Based on Nanotechnology

- Co-encapsulation Nanomaterial Drug Delivery System for Nanoformulations

- Selective Organ Targeting Nanoparticle Platform for Nanoformulations

- Nanoformulation Technology for Biologics

- Nanochip Technology for Nanoformulations

- Applications

- Order Online

- Company

- Inquiry

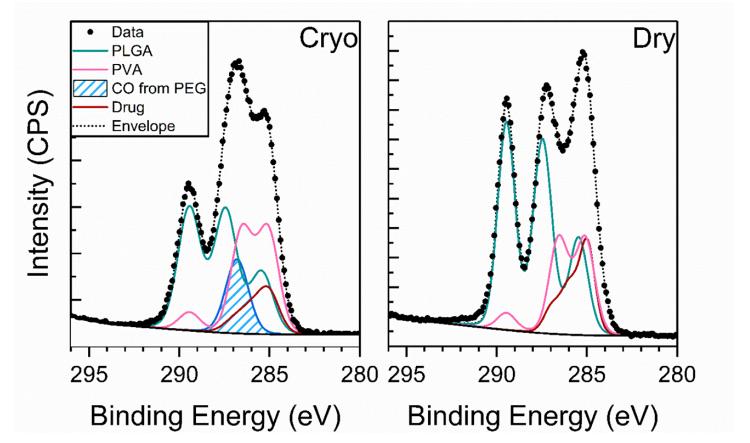

Fig.1 Carbon 1s spectra for the polymeric particles. (David J H Cant, et al. 2023)

Fig.1 Carbon 1s spectra for the polymeric particles. (David J H Cant, et al. 2023)