Zeta Potential Measurement Service for Nanoformulations

Inquiry

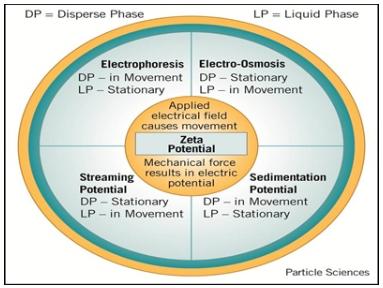

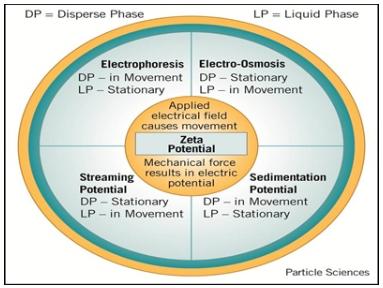

The surface charge of nanoformulations can impact their aggregation behavior, stability, cellular interactions, and distribution within the body. This charge is influenced by factors such as particle size, composition, and the medium in which the nanoformulation is dispersed. Zeta potential, which is commonly used to assess surface charge, provides insights into the electronic state at the nanoparticle surface and helps predict the stability of formulations containing these particles. CD Formulation offers zeta potential measurement services for nanoformulations using techniques such as electrophoresis, electroosmosis, streaming potential, and the sedimentation method to cater to various requirements.

Why is Zeta Potential of Nanoformulations Important?

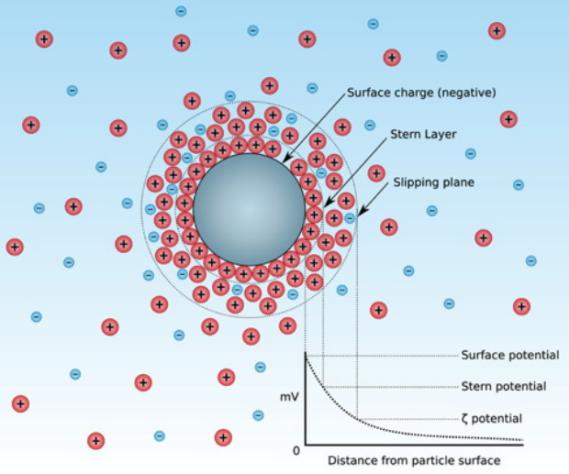

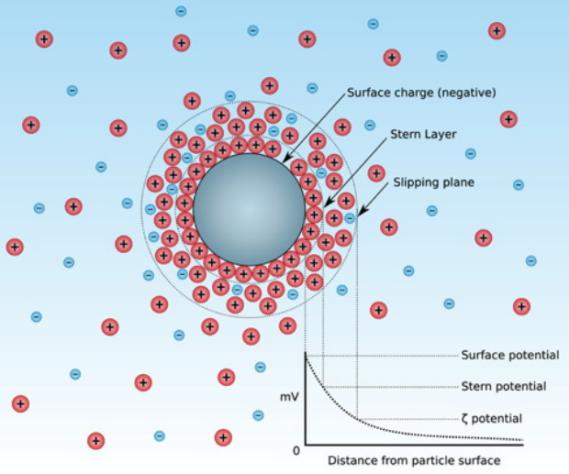

Zeta potential refers to the potential of the shear plane, also called electrokinetic potential (ζ-potential). It is an important indicator to characterize the stability of colloidal dispersions.

Fig.1 Schematic representation of the ionic concentration and potential difference as a function of distance from the charged surface of a particle suspended in a dispersion medium. (Pavan M. V. Raja, et al. 2013)

Fig.1 Schematic representation of the ionic concentration and potential difference as a function of distance from the charged surface of a particle suspended in a dispersion medium. (Pavan M. V. Raja, et al. 2013)

Zeta potential can help us understand the actual charge amount on the surface of colloidal nanoparticles caused by changes in the electrical double layer in different systems. If the absolute value of the zeta potential of the nanoparticles is high, it means that their surfaces have more charges, and they will tend to repel each other, thereby achieving the stability of the entire system. If the particles as a whole have little charge, that is to say, the absolute value of their zeta potential is very low, they will tend to attract each other, making the entire system unstable. Zeta potential plays an important role in nanoformulations as follows.

- Zeta potential can be used to measure the solid-liquid interface electrical properties of particles in a dispersed system, to measure the interfacial electrical properties of emulsion droplets, to determine the isoelectric point, and to study the mechanism of the interface reaction process.

- Zeta potential is used to determine the positive and negative surface charges of nanoparticles and is used to guide the next step of nanoformulation development, modification, or application of different drug delivery systems.

- Zeta potential is used to determine and guide the improvement of the stability of nanoparticles in solution systems.

Our Zeta Potential of Nanoformulations Measurement Process

The important significance of zeta potential is that its value is related to the stability of colloidal dispersion. Zeta potential is a measure of the strength of mutual repulsion or attraction between particles.

Table 1 Stability behavior of the colloid particles with respect to zeta potential.

| Zeta Potential (mV) |

Stability Behavior of The Particles |

| 0 to ± 5 |

Rapid Coagulation or Flocculation |

| ± 10 to ± 30 |

Incipient Instability |

| ± 30 to ± 40 |

Moderate Stability |

| ± 40 to ± 60 |

Good stability |

| More than ± 61 |

Excellent stability |

Our zeta potential measurement process includes simple three steps, such as sample preparation, Zeta potential measurements, and calculating Zeta potential.

Sample Preparation

Since the zeta potential of particles depends on the particles and the dispersion medium, the sample preparation needs to follow a procedure that can change the zeta potential from the original system to a diluted sample that can be used for measurement.

Zeta Potential Measurements

We can detect zeta potential using different techniques, such as electrophoresis, electro-osmosis, streaming potential, or sedimentation potential method.

Calculations of Zeta Potential

We have lots of experience in different ways of calculating zeta potential, such as zeta potential in electrophoresis and zeta potential in electroosmosis.

Our Zeta Potential of Nanoformulations Measurement Methods

After a long period of exploration and development, we can select appropriate and robust zeta potential measurement methods according to the different requirements of customers via electrophoresis, electro-osmosis, streaming potential, and sedimentation potential methods.

Electrophoresis Method

Using a zeta potential analyzer that operates on Doppler electrophoretic light scattering, we introduce the liquid sample into an electric field with voltage at each end. Laser Doppler velocimetry is then utilized to determine the speed at which colloidal particles migrate. By analyzing the correlation between zeta potential and migration rate, we can determine the zeta potential of the solution under examination.

Electroosmosis Method

According to the corresponding relationship between the fluid flux and the applied electric field current, the zeta potential is obtained with the help of the Smoluchowski equation.

Streaming Potential Method

Based on our advanced equipment, this equipment uses a vacuum to suck the fiber suspension toward the filter to form a fiber mat on the filter and then measures the potential difference between a pair of electrodes installed at both ends of the fiber mat. Then the potential value when a certain vacuum pressure is applied to both sides of the fiber pad is compared with the reference potential value when no vacuum pressure is applied to obtain the zeta potential.

Sedimentation Potential Method

Under the action of mechanical external force, the liquid to be measured flows along the wall of the capillary, and the counterions in the diffusion layer flow with the liquid to be measured and accumulate at one end of the tube. The zeta potential is obtained by measuring the flow current formed during the process.

Fig.2 Relationship between the four types of electrokinetic phenomena. (Pavan M. V. Raja, et al. 2013)

Fig.2 Relationship between the four types of electrokinetic phenomena. (Pavan M. V. Raja, et al. 2013)

In addition, CD Formulation has also developed some comprehensive methods for measuring zeta potential, such as phase analysis light scattering (PALS), electrophoretic light scattering (ELS), and tunable resistive pulse sensing (TRPS), which are used to measure the surface charge of ultrafiltration, nanofiltration and reverse osmosis membranes.

Why Choose Us to Measure Zeta Potential of Nanoformulations?

- We are good at testing the zeta potential of liposomes, solid lipid nanoparticles, and micelles using light scattering techniques such as laser Doppler microelectrophoresis (electrophoretic light scattering, ELS)

- Our core team has rich experience and can provide a quick response to your detailed requirements for zeta potential measurement immediately.

- We have complete analysis and testing service management specifications, a relatively fast sample circulation cycle, and can measure zeta potential efficiently and send you test reports.

Published Data

Technology: Molecular Dynamics (MD) Simulation

Journal: VIEW

IF: 8.6

Published: 2022

Results:

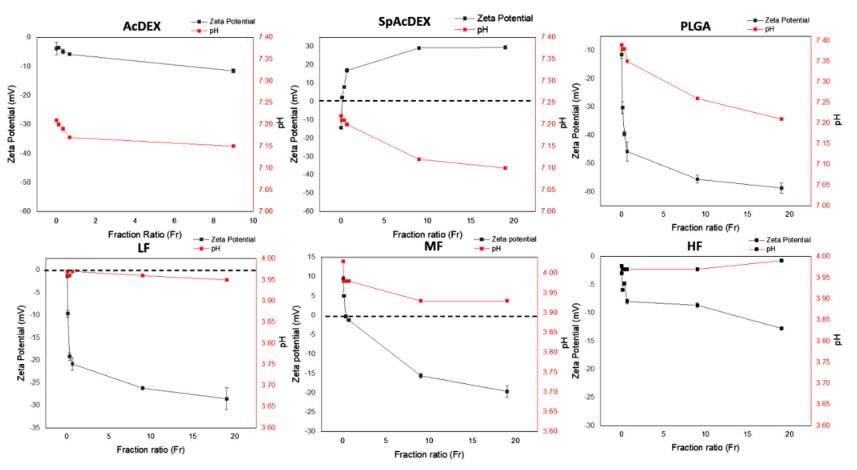

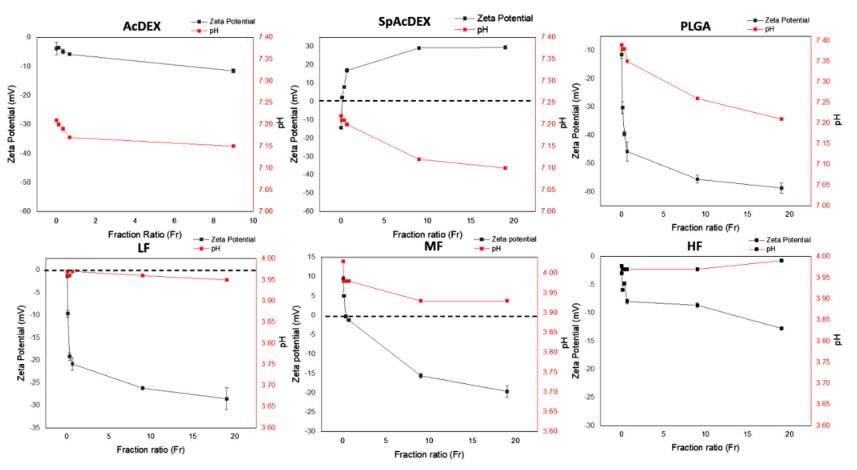

The authors used a simple experimental approach to measure the zeta potential of common polymer nanoparticle systems at different buffer concentrations, pH values, and nanoparticle-to-buffer fraction ratios. And zwitterionic/cationic buffer molecules were observed to significantly interfere with the electrokinetic properties of structurally diverse polymer nanoparticles by causing zeta potential suppression or even inversion during experiments. The authors study intermolecular interactions of nanoparticles and other complex molecules through molecular dynamics (MD) simulations. This study found that non-covalent interactions play an important role in changing the observed zeta potential values.

Fig.3 Zeta potential of polymer particles. (Wali Inam, et al. 2022)

Fig.3 Zeta potential of polymer particles. (Wali Inam, et al. 2022)

CD Formulation possesses state-of-the-art equipment and a skilled R&D team to provide zeta potential measurement support for your nanoformulation development needs. If you are interested in our services, please kindly contact us for detailed communication.

References

- Pavan M. V. Raja & Andrew R. Barron. 2.5: Zeta Potential Analysis. Physical Methods in Chemistry and Nano Science. 2013, https://chem.libretexts.org/Bookshelves/Analytical_Chemistry/Physical_Methods_in_Chemistry_and_Nano_Science_(Barron)/02:_Physical_and_Thermal_Analysis/2.05:_Zeta_Potential_Analysis.

- Wali Inam, Rajendra Bhadane , Rukiye Nur Akpolat, et al. Interactions between polymeric nanoparticles and different buffers as investigated by zeta potential measurements and molecular dynamics simulations. VIEW. 2022,DOI: 10.1002/viw.20210009.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 Schematic representation of the ionic concentration and potential difference as a function of distance from the charged surface of a particle suspended in a dispersion medium. (Pavan M. V. Raja, et al. 2013)

Fig.1 Schematic representation of the ionic concentration and potential difference as a function of distance from the charged surface of a particle suspended in a dispersion medium. (Pavan M. V. Raja, et al. 2013) Fig.2 Relationship between the four types of electrokinetic phenomena. (Pavan M. V. Raja, et al. 2013)

Fig.2 Relationship between the four types of electrokinetic phenomena. (Pavan M. V. Raja, et al. 2013) Fig.3 Zeta potential of polymer particles. (Wali Inam, et al. 2022)

Fig.3 Zeta potential of polymer particles. (Wali Inam, et al. 2022)