Microneedle Technology for Transdermal Delivery

Inquiry

Microneedles (MNs) are microscopic needles, typically tens to hundreds of microns long, designed using microelectronic or micro-molding technology. They can painlessly penetrate the epidermis to enhance drug absorption while causing minimal irritation. CD Formulation applies cutting-edge microneedle technology to create non-invasive, safe, and highly effective drug delivery systems, assisting researchers in advancing pharmaceutical development.

About Microneedle Technology

MNs are currently widely used to promote drug absorption in transdermal drug delivery. MNs can penetrate the stratum corneum of the skin and reach the dermis without damaging the nerve endings and blood vessels in the dermis. Therefore, compared with subcutaneous injection, MNs are less painful and more comfortable when administered. Compared with the energy-driven method, this technology has considerable advantages. For example, since the stratum corneum is bypassed, the use of MNs can better deliver large molecules. In addition, the skin can recover quickly after the removal of MNs; therefore, this can reduce irritation or secondary infection at the site of use. The materials of MNs are usually made of biocompatible substances or biodegradable polymers. It is important to ensure that the MN material is safe and does not cause an inflammatory response after insertion.

Our Microneedling Technique Types

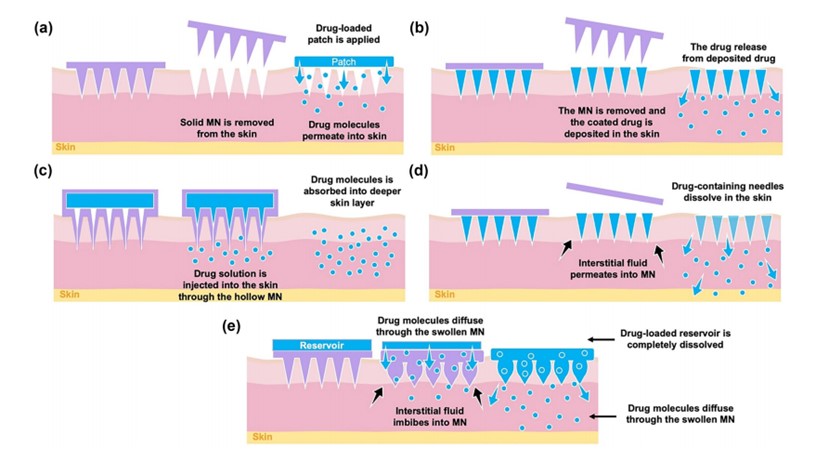

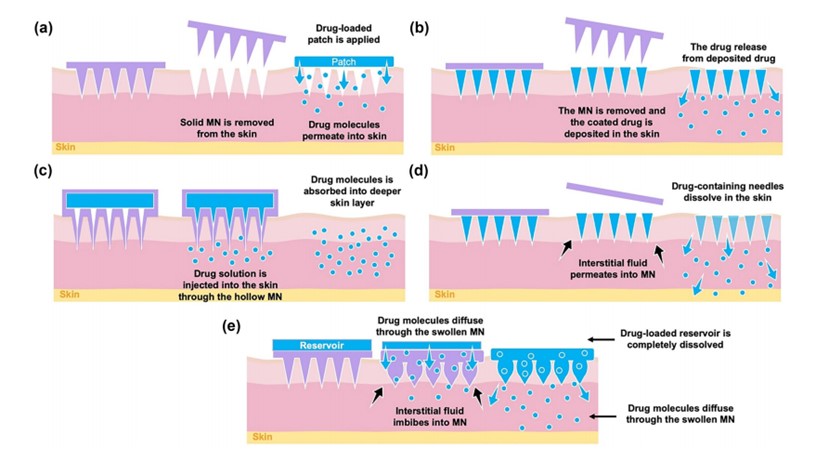

- Solid microneedles: Used for skin pretreatment to create paths for drugs.

- Coated microneedles: Have drug solution on their surface. They pierce the skin to release the drug.

- Dissolving microneedles: Made of biodegradable materials. They dissolve and release the drug after entering the skin.

- Hollow microneedles: Filled with drug solution. They inject the solution directly into the dermis.

Fig.1 Drug delivery approach via different types of MN: (a) solid, (b) coated, (c) hollow, (d) dissolving and (e) hydrogel-forming MNs. (Delly Ramadon, et al. 2021)

Fig.1 Drug delivery approach via different types of MN: (a) solid, (b) coated, (c) hollow, (d) dissolving and (e) hydrogel-forming MNs. (Delly Ramadon, et al. 2021)

Microneedle Technology Applications

We utilize microneedles to effectively overcome the skin's barrier, enabling the development of transdermal drug delivery for a wide range of molecules, from small drugs to large protein antibodies and vaccines.

- Small molecule drug: We can develop microneedles designed for the delivery of small molecule drugs, ensuring rapid release and a sustained effect.

- Protein polypeptide: We can prepare hyaluronic acid soluble microneedles for the efficient delivery of protein polypeptides. These microneedles dissolve quickly, releasing the drug rapidly. The drug is then concentrated in the epidermis and dermis.

- Vaccine: Microneedle vaccination offers the benefits of high antigen stability, low dosage, and potent immunogenicity. Additionally, microneedle inoculation typically does not require cold chain storage, reducing costs.

- Aesthetic applications: We can also develop microneedles utilized in aesthetic applications, such as scar reduction, skin whitening, wrinkle removal, and freckle elimination.

Explore Our Technology Platform for Microneedle Preparation

| Technologies |

Specific Information |

| Micromolding technology |

- It can effectively and repeatedly produce standardized microneedles, suitable for mass production.

|

| Laser engraving technology |

- Use a high-energy laser beam to directly engrave the shape of the microneedle on the material. Suitable for preparing microneedles on polymer materials.

|

| Chemical etching method |

- Use chemical reagents to corrode the surface of the material to form a microneedle structure.

|

| 3D printing technology |

- 3D printing technology is highly customizable can be molded in one step and can produce microneedles with complex geometries and structures.

|

What Transdermal Microneedle Patches Can We Develop?

Transdermal Solid Microneedle Patch Development

Micron-scale pores created on the skin surface help enhance drug penetration, providing a painless and minimally invasive method for delivering small molecules and vaccines transdermally.

Transdermal Coated Microneedle Patch Development

The drug is applied to solid microneedles, which penetrate the skin to release the drug. This method is adaptable for various drug types, with customizable needle shapes and materials based on specific needs.

Transdermal Hydrogel Microneedle Patch Development

Hydrogel microneedles, composed of cross-linked polymers, absorb interstitial fluid and create a continuous, non-blocking channel for drug delivery. They offer higher drug loading, and cost-effectiveness compared to solid microneedles.

Why Choose CD Formulation?

- Our company has skilled researchers. They know a lot about microneedle technology and have real-world experience. They keep improving and developing it.

- Our company uses top-notch microneedle machines and technology from around the world. This includes high-precision laser cutters, micro-molders, and 3D printers.

- We have built a complete R&D experimental platform. Including drug formulation laboratories, biocompatibility testing laboratories, skin permeability testing laboratories, etc. These provide strong support for the research development and application of microneedle technology.

Publication Data

Technology: Microneedles Technology

Journal: Nanoscale Adv

IF: 4.6

Published: 2023

Results: MNs have been widely used in the transdermal delivery of numerous kinds of drugs. MNs can penetrate the SC of the skin and reach the dermis without breaching nerve endings and blood vessels in the dermal layer. Consequently, upon administration, MNs are less painful and more comfortable with hypodermic injections. Furthermore, dissolving and hydrogel-forming MNs can avoid the need for sharps waste disposal and do not contribute to blood-borne diseases the way traditional needle and syringe devices can. For instance, since the SC is bypassed, delivery of macromolecules is more feasible using MN. In addition, the skin can quickly recover after the MN is removed; thus, this may prevent irritation or secondary infections at the application site. In terms of materials, MNs are generally manufactured using biocompatible substances or biodegradable polymers. It is important to ensure that MN materials are safe and do not induce inflammation response after the insertion. For routine use, such as in insulin therapy, MNs are possible for self-administration and easy to apply on the skin. The benefits documented above have shown that MNs are designated as a promising strategy to improve drug permeation into the skin.

We are committed to further improving microneedle materials, structures, and production processes to optimize drug delivery efficiency and safety. Additionally, we continue exploring microneedle applications in medical and cosmetic fields, offering researchers a range of innovative solutions. Contact us, and our team will respond within three business days.

References

- Delly Ramadon, Maeliosa T. C. McCrudden, et al. Enhancement strategies for transdermal drug delivery systems: current trends and applications. Drug Delivery and Translational Research. 2022, 12, 758–791.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 Drug delivery approach via different types of MN: (a) solid, (b) coated, (c) hollow, (d) dissolving and (e) hydrogel-forming MNs. (Delly Ramadon, et al. 2021)

Fig.1 Drug delivery approach via different types of MN: (a) solid, (b) coated, (c) hollow, (d) dissolving and (e) hydrogel-forming MNs. (Delly Ramadon, et al. 2021)