3D Printing Technology for Oral Thin Film Manufacturing

Inquiry

3D printing technology has been utilized to develop novel and complex drug delivery systems that are almost impossible to produce by conventional formulation techniques. For example, this technique may be employed to produce oral thin film with multilayers of active ingredients. CD Formulation offers 3D printing technology to solve the formulation problems of producing oral thin films.

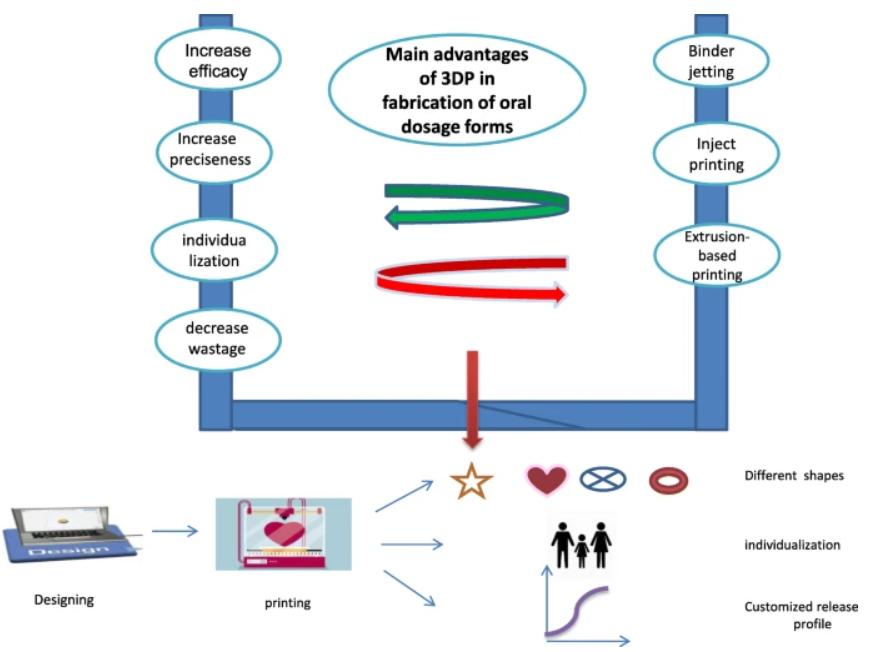

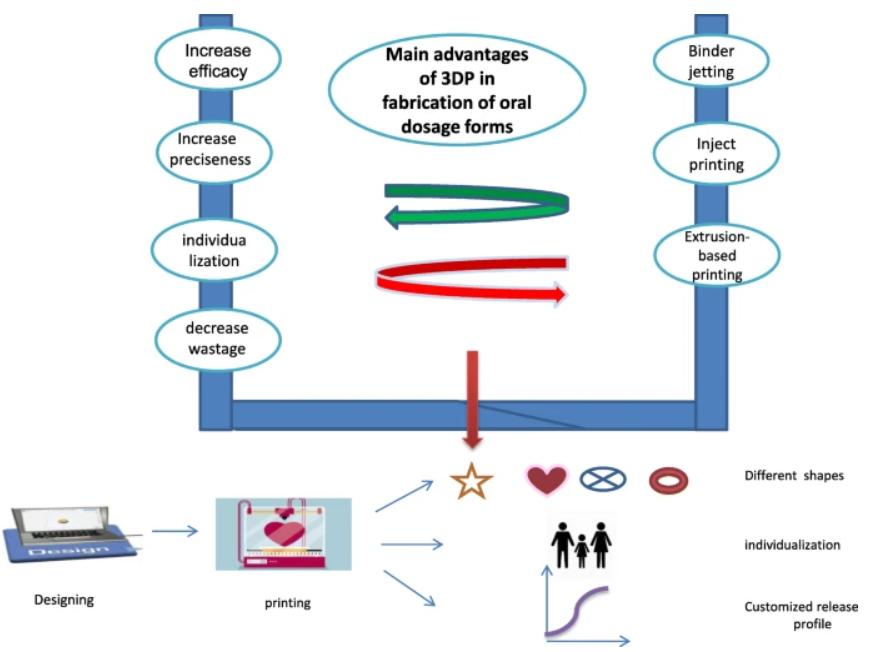

Fig.1 Main advantages of 3D printing technology in pharmaceutical applications. (Nasim Samiei, 2020)

Fig.1 Main advantages of 3D printing technology in pharmaceutical applications. (Nasim Samiei, 2020)

Combination of 3D Printing Technology

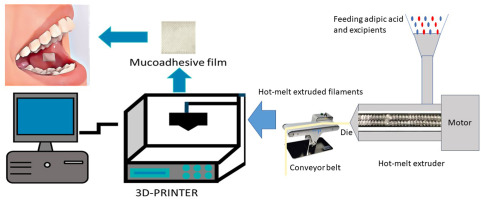

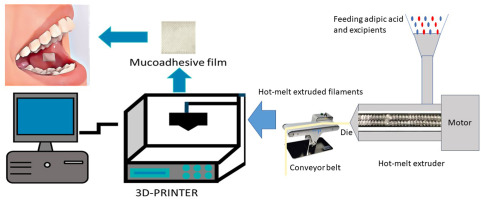

CD Formulation can combine 3D printing technology and hot melt extrusion technology, which can improve the physical properties of formulations and produce oral thin film with preferred qualities such as faster dissolution rate of drugs.

Fig.2 Mucoadhesive buccal films are prepared by coupling HME and 3D printing technologies. (Rasha M. Elkanayati, et al., 2022)

Fig.2 Mucoadhesive buccal films are prepared by coupling HME and 3D printing technologies. (Rasha M. Elkanayati, et al., 2022)

Our 3D Printing Technologies for Oral Thin Film Manufacturing

Currently, oral thin films are reserved for potent agents due to the limited capacity of drug incorporation. 3D printing techniques could be used to superimpose the layers of oral thin film to accommodate more active ingredients per unit area. This technology can also solve incompatible ingredients by compartmentalizing the buccal film layers. In addition, 3D printing technology can provide a platform for the long-term control of drug release, reducing the frequency of administration. CD Formulation offers an advanced 3D printing technology platform for oral thin film manufacturing, helping clients solve the formulation problems of producing oral thin films. Our 3D printing techniques include:

| Printing Techniques |

Advantages |

| 3D Inkjet Printing |

- Suitable for personalized oral thin film

- The complexity of structured layers does not significantly impact manufacturing time

- Wide range of filaments available

|

| Extrusion-Based 3D Printing Methods |

- Shapes' reproducibility and API concentrations' uniformity

- Different release profiles are achievable by changing the 3D model design, infill percentage, or surface area

|

| Pressure-Assisted Microsyringe (PAM) |

- Continuous 3D printing at room temperature

- Suitable for thermo-labile drugs

|

| Semisolid Extrusion (SSE) |

- The computer-controlled process with reduced production time, manual labour, and costs

|

| Direct Powder Extrusion (DPE) |

- Significantly reduced production cost

- Accelerated formulation development

- Good resolution and low cost

|

| Liquid Crystal Display 3D Printing |

- Safe visible light-induced photopolymerization

|

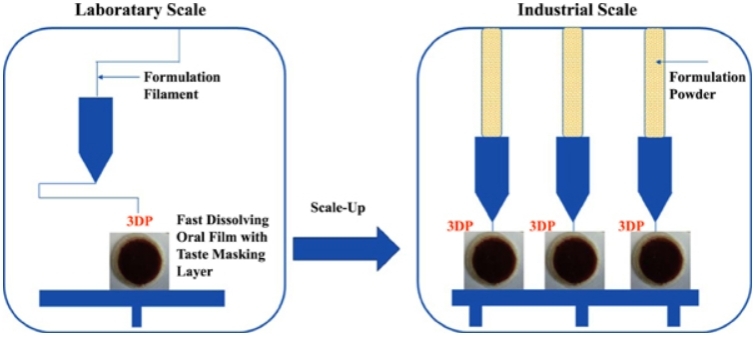

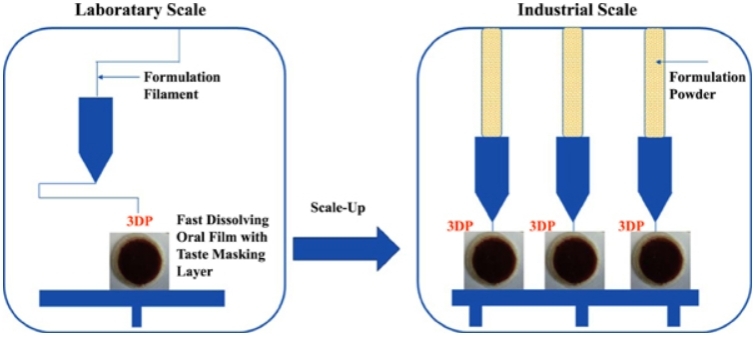

3D Printing Technology for Oral Thin Film Commercial Manufacturing

We compared the production of oral thin film by 3D printing to conventional methods such as solvent casting, hot melt extrusion, etc. We also evaluated the need for novel methods of producing oral thin film, and why 3D printing may be able to meet the shortfalls of oral thin film production. The challenges of producing 3D printed oral thin film are identified at a commercial scale by referring to the identification of suitable materials, hardware, quality control tests and analytical technology processes. Our 3D printing techniques can meet production from laboratory scale to commercial scale.

Fig.3 3D Printing of Fast Dissolving Oral Films for Commercial Production. (Touraj Ehtezazi, et al., 2020)

Fig.3 3D Printing of Fast Dissolving Oral Films for Commercial Production. (Touraj Ehtezazi, et al., 2020)

Discover Oral Thin Film Preparation Techniques

As a leader in contract R&D for oral thin film formulations, our company leverages decades of expertise to identify and refine optimal preparation techniques, ensuring superior-quality thin films.

Preparation Method Screening of Oral Thin Films

Our proficiency spans various preparation techniques, such as semi-solid casting, solvent casting, and hot-melt extrusion. Employing cutting-edge technology and scientific expertise, we rigorously test and customize each method to fit the specific requirements of your project.

Why Choose CD Formulation?

- Expertise: We have a dedicated team of oral film drug development and ensure that all aspects of the 3D printing service we offer meet the highest scientific standards.

- Flexibility: We offer flexible 3D printing preparation processes that can be tailored to customer requirements to maximize the development needs of customers.

- Rich Experience: We have professional 3D printing technicians who can accurately control the printing process.

Published Data

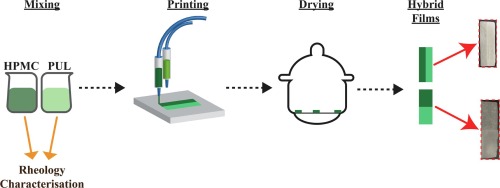

Technology: 3D printing technology

Journal: International Journal of Pharmaceutics

IF: 5.3

Published: 2021

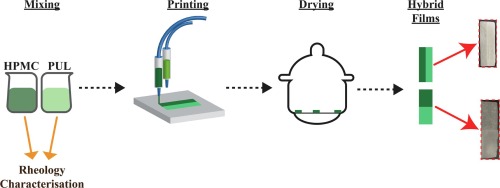

Results: This study used three-dimensional (3D) printing to produce hybrid film structures of PUL and hydroxypropyl methylcellulose (HPMC), which were loaded with caffeine as a model drug. The results revealed that 3D printing could modify the mechanical properties of PUL whilst circumventing the issues associated with immiscibility.

Fig.4 3D printing of oral films based on pullulan and hydroxypropyl methylcellulose. (M. Elbadawi, et al., 2021)

Fig.4 3D printing of oral films based on pullulan and hydroxypropyl methylcellulose. (M. Elbadawi, et al., 2021)

CD Formulation is an industry leader in the formulation development of novel drug delivery systems, and our integration of 3D printing into the production of oral thin films has significantly advanced the field of drug delivery. If you require our 3D printing technology for oral thin film manufacturing services, please contact us by phone or email, and our colleagues will get back to you within three working days.

References

- Nasim Samiei. Recent trends on applications of 3D printing technology on the design and manufacture of pharmaceutical oral formulation: a mini review. Beni-Suef University Journal of Basic and Applied Sciences. 2020,9(2):2-12.

- M. Elbadawi, D. Nikjoo, et al. Pressure-assisted microsyringe 3D printing of oral films based on pullulan and hydroxypropyl methylcellulose. International Journal of Pharmaceutics. 2021, Vol(595).

- Touraj Ehtezazi, Marwan Algellay, et al. Next Steps in 3D Printing of Fast Dissolving Oral Films for Commercial Production. Recent Patents on Drug Delivery & Formulation. 2020, Vol(14):5-20.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 Main advantages of 3D printing technology in pharmaceutical applications. (Nasim Samiei, 2020)

Fig.1 Main advantages of 3D printing technology in pharmaceutical applications. (Nasim Samiei, 2020) Fig.2 Mucoadhesive buccal films are prepared by coupling HME and 3D printing technologies. (Rasha M. Elkanayati, et al., 2022)

Fig.2 Mucoadhesive buccal films are prepared by coupling HME and 3D printing technologies. (Rasha M. Elkanayati, et al., 2022) Fig.3 3D Printing of Fast Dissolving Oral Films for Commercial Production. (Touraj Ehtezazi, et al., 2020)

Fig.3 3D Printing of Fast Dissolving Oral Films for Commercial Production. (Touraj Ehtezazi, et al., 2020) Fig.4 3D printing of oral films based on pullulan and hydroxypropyl methylcellulose. (M. Elbadawi, et al., 2021)

Fig.4 3D printing of oral films based on pullulan and hydroxypropyl methylcellulose. (M. Elbadawi, et al., 2021)