Hot Melt Extrusion Technology for Oral Thin Film Manufacturing

Inquiry

Hot melt extrusion technology is a well-understood and established method of production, which has a lengthy history in plastic and food processing and is experiencing increasing popularity in the oral thin film pharmaceutical industry. Oral thin film formulations for hot melt extrusion typically consist of combinations of API, polymers, plasticizers or other excipients. Hot melt extrusion is an environmentally friendly technology with no need for solvents. CD Formulation has advanced equipment and professional technical teams that can help customers develop and manufacture high-quality oral thin films at both lab and production scales.

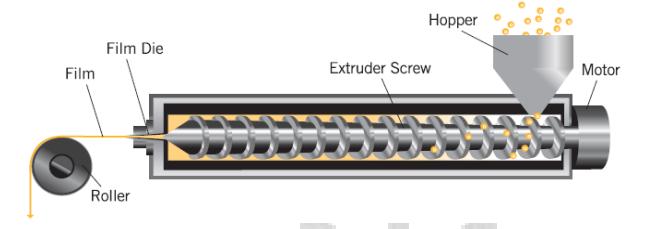

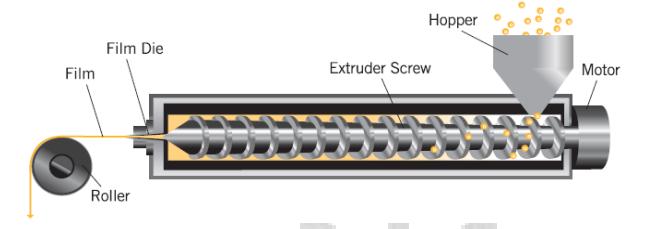

Fig.1 Diagram of a Film Extrusion System. (Ms. Prakruti M. Amin, et al., 2015)

Fig.1 Diagram of a Film Extrusion System. (Ms. Prakruti M. Amin, et al., 2015)

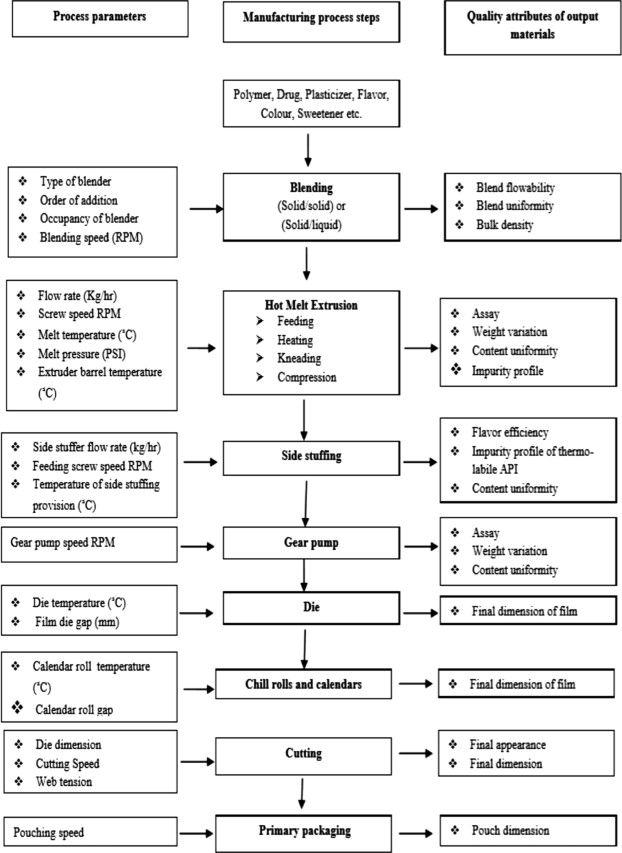

Crucial Process Parameter Involved in Using Hot Melt Extrusion Technology

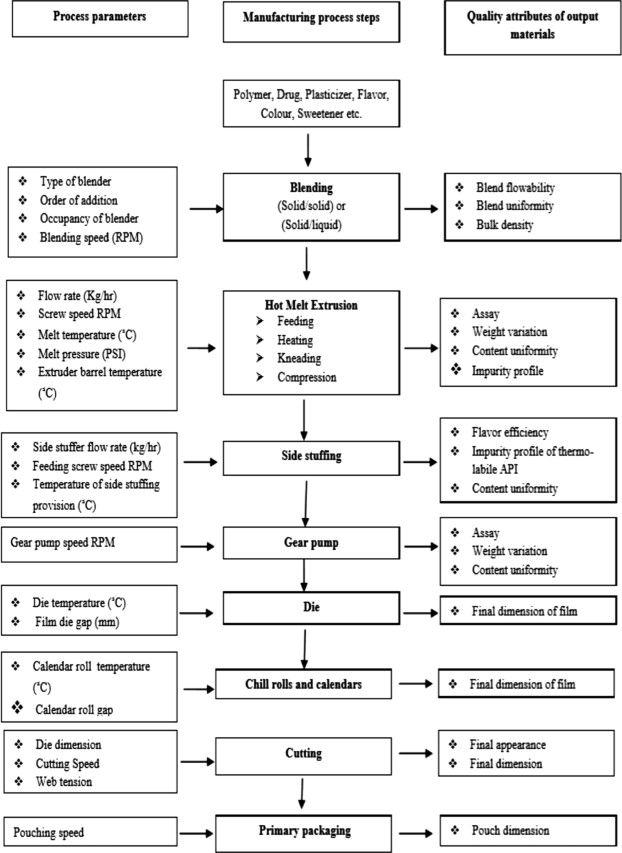

Parameters of the process that must be maintained in a narrow range to ensure acceptable oral thin film product quality are called critical process parameters. The crucial process parameter for hot melt extruded film is as follows:

Fig.2 Process mapping for identification of critical process parameters. (Rushiraj Jani, et al., 2015)

Fig.2 Process mapping for identification of critical process parameters. (Rushiraj Jani, et al., 2015)

Principle of Hot Melt Extrusion Technology

Hot melt extrusion works by melting the polymer in a twin-screw extruder. All ingredients are mixed and kneaded. As such, intense compounding occurs. The die is located at the end of the twin-screw extruder and determines the shape of the extrudate. The melt is squeezed from the hole in the die. Additional continuous processing can be provided by downstream equipment, including conveyors, take-off systems, cutters, etc. A sheet die is employed to determine the width and thickness of the thin film for the production of oral thin film.

Advantages of Hot Melt Extrusion Technology

- No need to use water.

- Fewer processing steps.

- Suitable dispersion mechanism for poorly soluble drugs.

- Less energy compared with high-shear methods.

- Minimum product waste.

- Possibility of scale-up.

- Reasonable control of operating parameters.

Problems with Hot Melt Extrusion Technology

Some problems have been found during the development and scale-up of oral thin films made by hot melt extrusion technology, such as the die swell phenomenon, fish eye formation, weight variation within film sheets, chemical stability of active during hot melt extrusion, etc.

Die Swell Phenomenon

The cross-section of the thin film increases upon leaving the die depending upon the viscoelastic property of polymers. So, the final dimension of the film changes due to this 'Die swell phenomenon'. This problem can be eliminated by low-speed screw operation, slow kneading, and long periods of gentle mixing rather than short periods of high-shear kneading.

Fish Eye Formation

Mixtures have an inherent tendency to agglomerate due to residual moisture in flavors or natural ingredients, and this agglomerate type of unevenness is called 'Fish eye'. High shear mixing must be applied from the beginning to eliminate "fish eye" formation in the mix.

Weight Variation within Film Sheets

Sometimes, uneven films are formed due to improper flow of powder blend through a hopper. If weight variation is due to the uneven pulsatile flow of molten mass, gear pump provisions can be installed near the end of the barrel.

Chemical Stability of API

In the hot melt extrusion process, many chemical reactions, such as hydrolysis and solvolysis due to residual moisture and solvent, initiate free radical generation at elevated temperatures. Preheated excipients are sometimes used to solve the problem of residual moisture and solvents.

Explore the Preparation Process of Hot Melt Extrusion Technology for Oral Thin Film

We have many years of experience in hot melt extrusion technology for oral thin film manufacturing, and we can quickly help customers solve the possible problems in this preparation technology and speed up the development of oral thin film.

Film-forming Agents Screening

In the hot melt extrusion process, film-forming agents significantly affect oral thin film solubility. Our professional excipient screening team selects suitable agents and resolves API recrystallization issues during preparation.

Why Choose CD Formulation?

- Our hot melt extrusion technology allows for the continuous and efficient production of oral thin films, leading to shorter manufacturing times and increased throughput.

- We are familiar with some problems that may arise when preparing orally soluble films using hot melt extrusion technology, and we can help customers promptly by providing solutions.

- We have a variety of hot melt extrusion equipment to choose from, which can not only meet the needs of laboratories but also meet the needs of large-scale production.

Published Data

Technology: Hot-melt extrusion technology

Journal: European Journal of Pharmaceutics and Biopharmaceutics

IF: 4.4

Published: 2017

Results: The main objective of this novel study was to develop chlorpheniramine maleate orally disintegrating films (ODF) using hot-melt extrusion technology and evaluate the characteristics of the formulation using in vitro and in vivo methods. Modified starch with glycerol was used as a polymer matrix for melt extrusion. Sweetening and saliva-simulating agents were incorporated to improve palatability and lower the disintegration time of film formulations. A standard screw configuration was applied, and the last zone of the barrel was opened to discharge water vapour, which helped to manufacture non-sticky, precise, and uniform films.

Fig.3 Development of an oral fast disintegrating anti-allergic film using hot-melt extrusion technology. (Manjeet B. Pimparade, et al., 2017)

Fig.3 Development of an oral fast disintegrating anti-allergic film using hot-melt extrusion technology. (Manjeet B. Pimparade, et al., 2017)

CD Formulation can help you solve problems with hot melt extrusion technology to prepare thin oral films. If you require our hot melt extrusion technology for oral thin film manufacturing services, please contact us by phone or email, and our colleagues will get back to you within three working days.

References

- Ms. Prakruti M. Amin, Prof. A. B. Gangurde, et al. Oral Film Technology: Challenges and Future Scope for Pharmaceutical Industry. IJPPR. 2015, Vol (3):183-203.

- Manjeet B. Pimparade, Anh Vo, et al. Development and evaluation of an oral fast disintegrating anti-allergic film using hot-melt extrusion technology. European Journal of Pharmaceutics and Biopharmaceutics. 2017, Vol (119):81-90.

- Rushiraj Jani, Dasharath Patel. Hot melt extrusion: An industrially feasible approach for casting orodispersible film. Asian Journal of Pharmaceutical Sciences. 2015, Vol (10):292-305.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 Diagram of a Film Extrusion System. (Ms. Prakruti M. Amin, et al., 2015)

Fig.1 Diagram of a Film Extrusion System. (Ms. Prakruti M. Amin, et al., 2015) Fig.2 Process mapping for identification of critical process parameters. (Rushiraj Jani, et al., 2015)

Fig.2 Process mapping for identification of critical process parameters. (Rushiraj Jani, et al., 2015) Fig.3 Development of an oral fast disintegrating anti-allergic film using hot-melt extrusion technology. (Manjeet B. Pimparade, et al., 2017)

Fig.3 Development of an oral fast disintegrating anti-allergic film using hot-melt extrusion technology. (Manjeet B. Pimparade, et al., 2017)