Film-forming Material Evaluation of Oral Thin Film

Inquiry

The oral thin film is a new form of drug delivery, which can quickly dissolve and release drugs in the mouth, making it convenient for patients to take. The film-forming material is one of the key factors affecting the performance of oral thin film, and its action and mechanism have an important influence on the quality and efficacy of oral thin film. CD Formulation provides film-forming materials evaluation services based on the type of oral thin film customers want to customize.

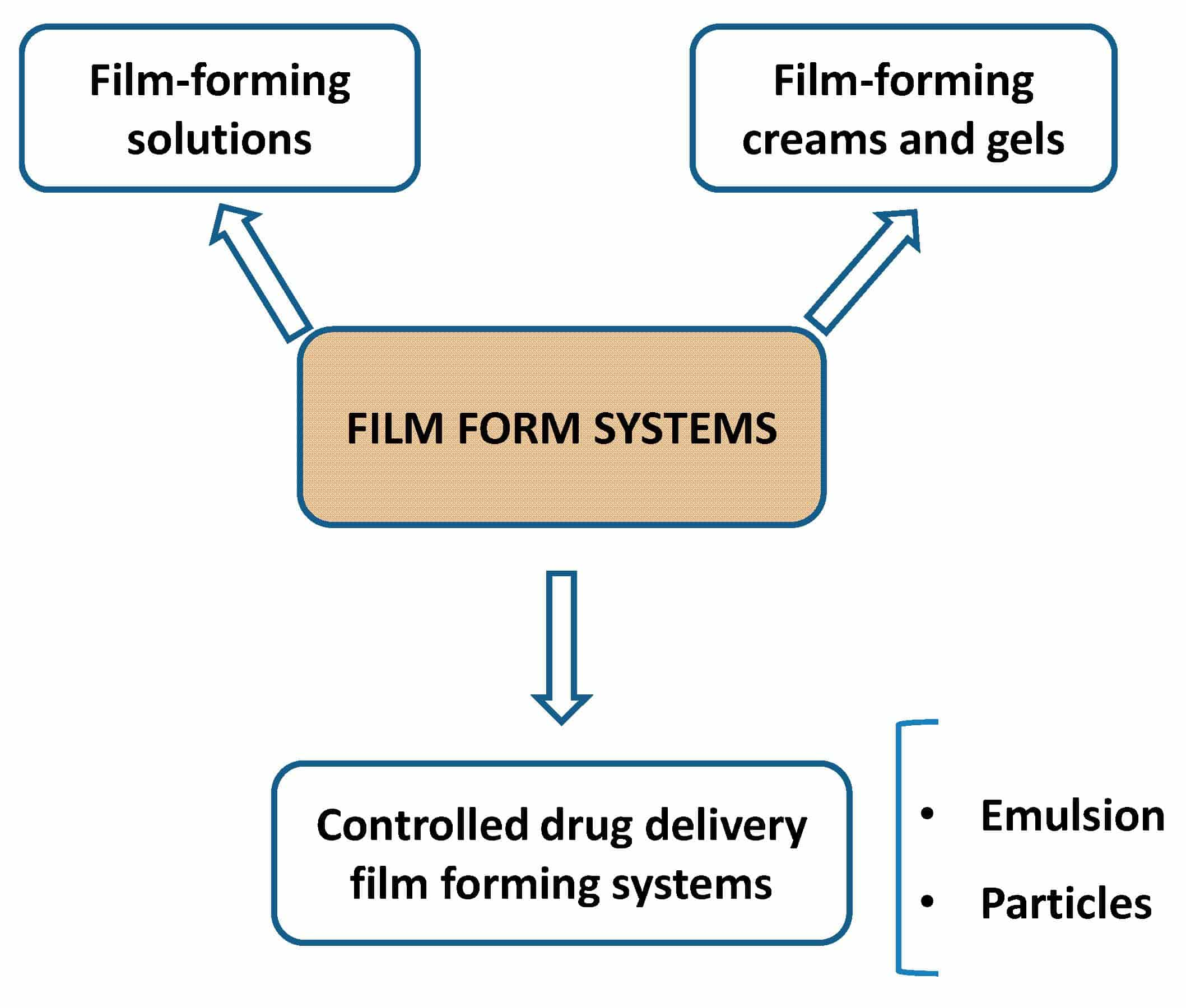

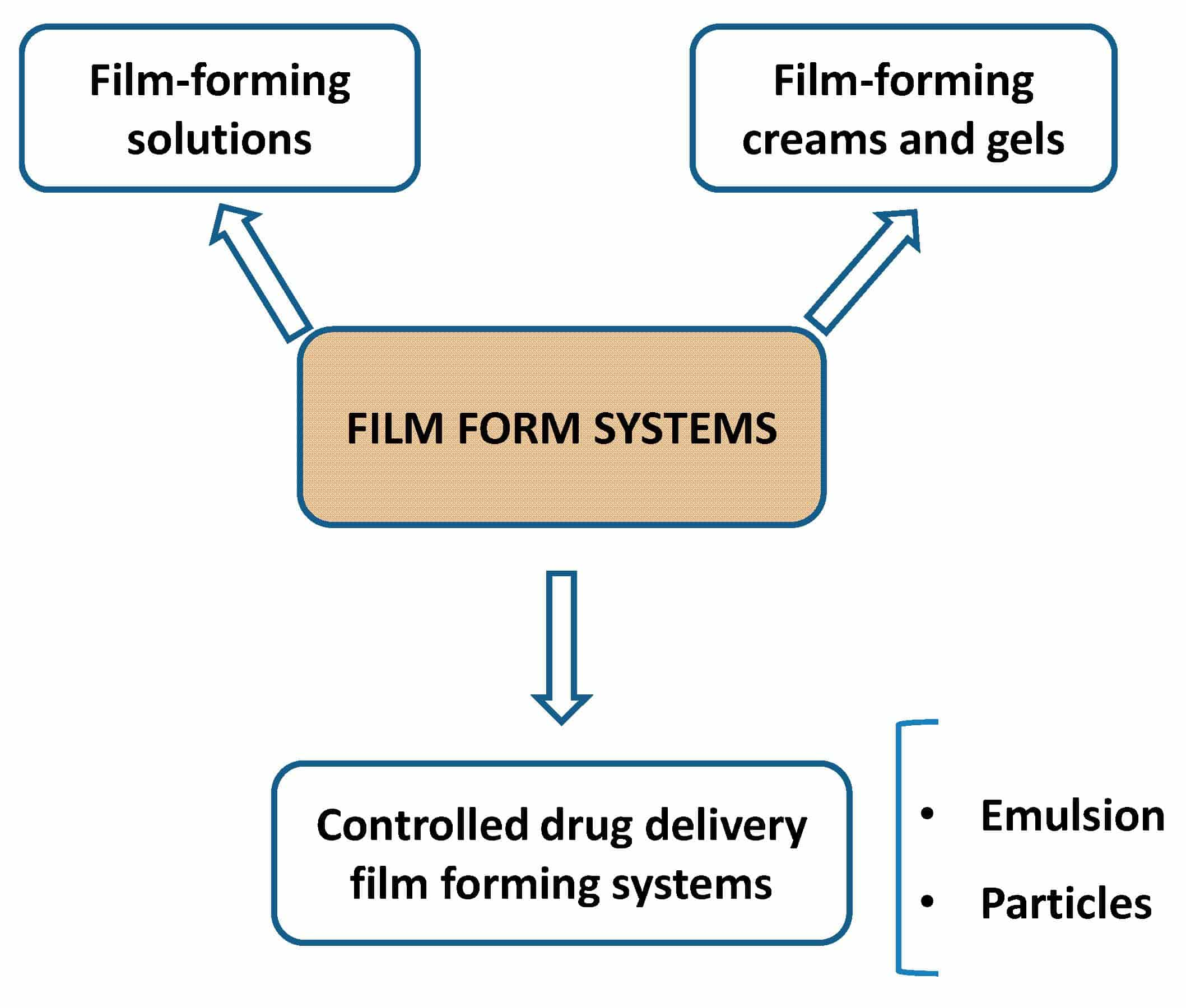

Fig.1 Illustrations of the generation of film-forming systems. (Thao T. D. Tran, et al., 2019)

Fig.1 Illustrations of the generation of film-forming systems. (Thao T. D. Tran, et al., 2019)

The Importance of Film-forming Material Evaluation for Oral Thin Film Development

- Endows the oral thin film with good solubility.

- Improve the stability of the oral thin film.

- Improve the mechanical strength of the oral thin film.

- Adjust the morphology and drug release rate of the oral thin film.

Our Film-forming Material Evaluation Services

CD Formulation usually starts from the type of oral thin film, preparation process and API properties, comprehensively evaluates and selects the most suitable film-forming materials from the following aspects to ensure the quality and efficacy of oral dissolved films and achieve good therapeutic effects:

Solubility Evaluation

The film-forming agent should have good solubility and be able to quickly form a mixture with saliva so that the oral thin film quickly releases the drug.

Stability Evaluation

The film-forming agent should have good stability and can resist the influence of the external environment, and it is not easy to have adverse reactions or degradation with other components.

Mechanical Strength Evaluation

The film-forming agent should be able to improve the mechanical strength of the oral thin film so that the oral thin film has a certain degree of flexibility, is easy to attach, and dissolves in the mouth.

Adhesion Evaluation

The film-forming agent should have good adhesion so that the oral soluble film can be rapidly attached and dissolved in the mouth to ensure the effective absorption of the drug.

Drug Release Rate Evaluation

The type and dosage of film-forming agent will also affect the morphology and drug release rate of oral thin film, we will choose according to specific needs.

Types and Peculiarity of Film-forming Material for Oral Thin Film

| Type of Film-forming Agent |

Common Model |

Peculiarity |

| Polyvinyl Alcohol |

04-88, 18-88 |

Polyvinyl alcohol is one of the most used "molding" film-forming agents, which can be used in the coating method and hot melt extrusion method, low price, and has good film-forming properties, and is the most widely used. |

| Polyethylene Oxide |

N10, N80 |

Polyethylene Oxide, with good water solubility and a wide molecular weight distribution range (100,000 ~7 million), is often used in controlled-release solid skeleton materials. It is often used as a film-forming agent in the sustained-release oral thin film. |

| Hydroxypropyl Methyl Cellulose |

E5, E15, E50 |

Hydroxypropyl methylcellulose, easily soluble in cold water, commonly used models are E5, E15, E50, etc., for "rigid" film-forming materials. |

| Hydroxypropyl Cellulose |

EF |

Hydroxypropyl cellulose can be dissolved in water or ethanol, but after being dissolved in ethanol, the structure is destroyed, and the film formation is poor. |

| Povidone |

K30 |

Povidone alone is less effective as a film-forming agent, but there are cases of povidone being used as a taste-masking agent in relevant literature. |

| Copovidone |

S630 |

Copovidone is not effective as a film-forming agent alone and is often used in combination with other film-forming agents. |

| Pullulan Polysaccharide |

/ |

Pullulan polysaccharide is mainly used in food and health products and is often used in combination with starch additives. |

| Other |

/ |

Natural adhesives can also be used as film-forming agents, but they are less used. |

Advantages of Our Film-forming Material Evaluation Services

- Reliable Supplier: We have several reliable suppliers of film-forming materials, we can help customers to purchase film-forming agents and complete the evaluation of film-forming agents according to customer requirements.

- High Quality: We have LC/MS/MS, UPLC (TUV, PDA, SQD), HPLC (UV, PDA, FLU, ELSD, RI), GC, GPC, SEC, KF, TOC, Maldi-TOF, etc., analytical technology platforms, which can carry out comprehensive analysis and evaluation of film-forming materials. Ensure that the film-forming agent complies with relevant regulations and regulatory standards.

- Rich Experience: Our expert team is familiar with the advantages and disadvantages of various film-forming materials and the development of oral thin films and can adjust the film-forming materials at any time according to the characteristics of the developed oral thin films.

Published Data

Technology: Film-forming polymers

Journal: IJCRT

IF: 8

Published: 2022

Results: The selection of polymer is a very important parameter and the most critical one in the successful preparation of oral film due to their mechanical strength & stiffness, which depends on the type and amount of polymer. we used to formulate the films, the polymers can be used alone or in combination to improve hydrophilicity, flexibility, mouth–feel, and solubility characteristics of fast-dissolving films. 45% w/w of the concentration of the polymer is used to develop an orally fast-dissolving strip. However, it can be increased up to 60-65% w/w to attain the desired characteristics. The physicochemical properties of the polymers chosen for film formulation are critical in defining the cast thin film oral dosage form's disintegration time.

CD Formulation has a staff specializing in the research and application of film-forming, who are very experienced in the selection of film-forming agents in the development of oral thin films and can provide scientific and reasonable evaluation services. If you have a requirement about our film-forming materials evaluation for oral thin film services, please contact us by phone or email, and our colleagues will reply to you within three working days.

References

- Thao T. D. Tran, Phuong H. L. Tran. Controlled Release Film Forming Systems in Drug Delivery: The Potential for Efficient Drug Delivery. Pharmaceutics. 2019: 290.

- Hemavathy S, Dr Priyanka Sinha, et al. A Detailed Account on Novel Oral Fast Dissolving Strips: Application and Future Prospects. IJCRT. 2022.Vol(10):778.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services