Nanocrystalline Technology for Nanoformulations

Inquiry

The nanocrystalline technology platform provides an excellent opportunity for the delivery of hydrophobic drugs. Nanocrystal technology has been widely studied and is well-suited for further exploration in the field of hydrophobic drug delivery. CD Formulation can provide our clients with nanocrystalline technology services for nanocrystals depending on our advanced nanocrystalline technology platform.

Advantages of Nanocrystals

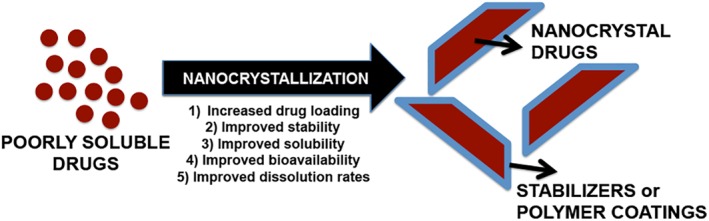

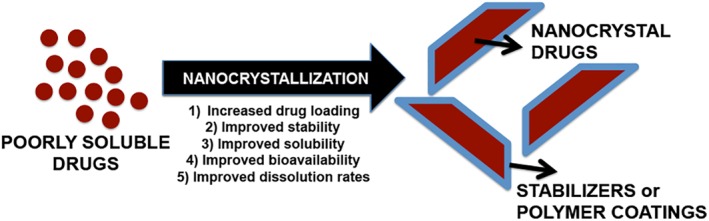

Nanocrystals are solid particles characterized by their small size, typically less than 1 μm in diameter, and possess crystalline properties. These particles consist entirely of the active drug or payload, eliminating the need for a carrier substance. The utilization of nanocrystalline technology enhances the solubility of hydrophobic drugs by increasing the surface area to volume ratio due to their nanoscale dimensions, thereby improving the dissolution rate. This technology is appealing for its simplicity in formulation, consistent composition, and cost-effectiveness. Additionally, nanocrystalline technology has the potential to address various challenges encountered in drug development, such as enhancing the bioavailability of poorly soluble drugs by converting them into nanocrystals, which can lead to improved dissolution rates and saturation solubility.

- Size below 1 μm

- 100% drug, no carrier

- Generally needed to be stabilized

- Crystalline or amorphous structure

- Increase in dissolution velocity

- Increase in saturation solubility

- The amorphous particle state offers advantages

Fig.1 Nanocrystallization of poorly soluble drugs improves physicochemical stability and drug bioavailability. (Maria Jarvis, et al. 2019)

Fig.1 Nanocrystallization of poorly soluble drugs improves physicochemical stability and drug bioavailability. (Maria Jarvis, et al. 2019)

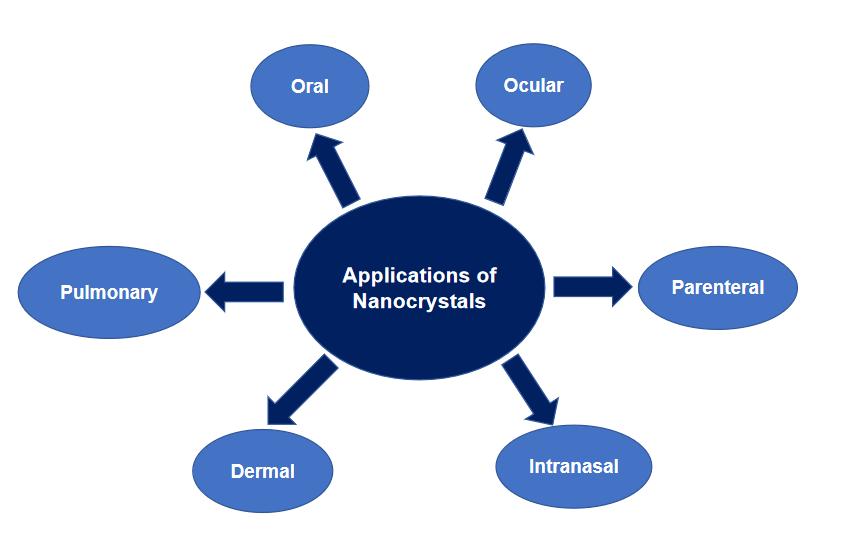

Applications of Nanocrystalline Technology

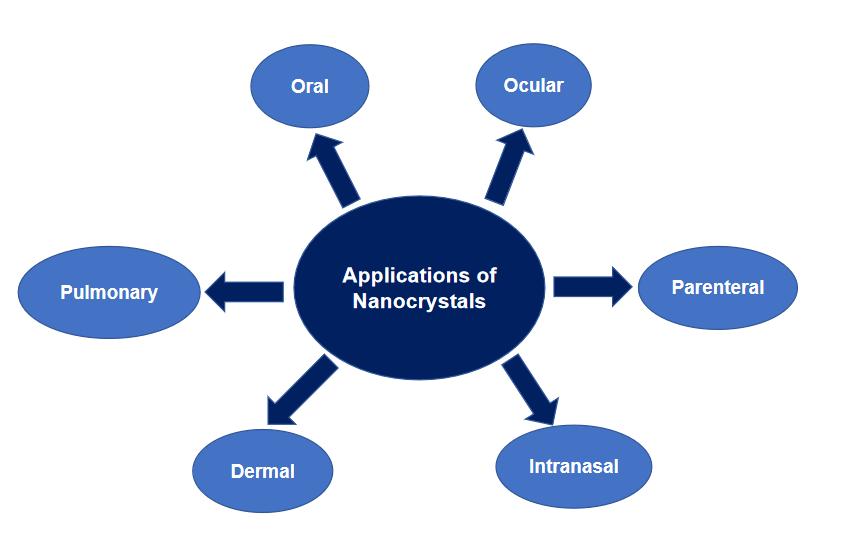

Because of its unique advantages, such as 100% effective load, nanocrystalline technology has broad applications in oral, parenteral, ocular, skin, lung and targeted drug delivery.

Oral Administration

Due to the small particle size of nanocrystals, it can enhance uniform distribution in the gastrointestinal tract and reduce local long-term concentration. Nanocrystals are also well tolerated in the mucosa due to minimal irritation to the stomach.

Parenteral Administration

Nanocrystals can improve the effectiveness of drugs through various parenteral routes such as intravenous, subcutaneous, intramuscular, intraarticular, and intraperitoneal. Due to the small particle size, nanocrystals can be administered via intravenous injection with reduced doses, rapid onset, and maximum bioavailability.

Pulmonary Drug Delivery

The deposition of drugs in the lungs can be controlled by the size distribution of nanocrystals. Aqueous nanosuspensions are prepared by ultrasonic methods for drug delivery to the lungs. Nanocrystals tend to adhere to the mucosal surface and prolong the residence time, thereby increasing the absorption of the drug. At the same time, the distribution of nanocrystals on the bronchial surface is more uniform.

Ophthalmic Drug Delivery

Nanocrystals have advantages such as long residence time, which is required for the effective treatment of most ocular diseases. It also provides low tension, and its performance depends on the intrinsic solubility of the drug in tears. Therefore, the intrinsic dissolution rate of the drug in tears determines its bioavailability and ocular release.

Targeted Drug Delivery

Targeted drug delivery allows the drug to accumulate in a specific targeted area for treatment. Nanocrystals used for targeted drug delivery have specific interactions with receptors in the target tissue. Targeting ligands and other functional groups can also be added to the surface of nanocrystals. In this way, nanocrystals can be integrated into various matrix structures and targeted to specific tissues/organs to exert their effects.

Fig.2 Different applications of nanocrystalline technology. (CD Formulation)

Fig.2 Different applications of nanocrystalline technology. (CD Formulation)

Nanocrystalline Technology at CD Formulation

Relying on our advanced design concept and nanocrystalline technology platform, CD Formulation focuses on the development and application of nanocrystal preparation and characterization technologies. We are able to design and prepare nanocrystals that meet the quality requirements of our customers based on their different needs.

Nanocrystal Production Technologies

Nanocrystals are usually produced by two methods, namely top-down and bottom-up.

Top-Down Methods: Top-down methods include methods such as media milling (pearl milling) and high-pressure homogenization (HPH). In these methods, large-sized particles are broken down into smaller sizes.

- Media milling: In media milling, the milling chamber is filled with milling beads, stabilizers, drugs, and dispersion media. The milling beads are made of stainless steel, glass, zirconium oxide, or highly cross-linked polystyrene resin. The drug crystals become nano-sized by a combination of collision with the milling beads, milling chamber, and high shear forces.

- High-pressure homogenization (HPH): In the HPH process, drug particles, either raw or dispersed in an aqueous medium containing surfactant, are converted into a micronized suspension by a sonicator, homogenizer, mortar and pestle, or jet mill.

Bottom-Up Methods: The bottom-up approach to growing nanocrystals from solutions involves two critical steps: nucleation and crystal growth.

- Precipitation: The most commonly used of the bottom-up methods is precipitation. Nanosuspension is made from small molecules completely dissolved in the corresponding anti-solvent, and then nanocrystals are obtained through two steps: nucleation and crystal growth.

- Acid-base neutralization: The drug is dissolved in an acidic organic solvent mixture, and then gradually added to the base until the solution is neutralized, thereby obtaining a nanosuspension, and then obtaining nanocrystals through nucleation and crystal growth.

- Other methods: Nanosuspensions can also be prepared using microfluidic nanoprecipitation processes, spray drying, electrospraying, aerosol flow reactors, and finally obtaining nanocrystals.

Nanocrystal Characterization Technologies

Properties such as crystallinity, size, shape, surface charge, and the type of stabilizers or polymer coatings used during formulation can affect the therapeutic efficacy of nanocrystals. Therefore, relying on our advanced instrumentation, we have built a nanocrystal characterization technology platform to monitor the properties of nanocrystals in real time to ensure that our customized nanocrystals meet the expected quality requirements.

Highlights of Our Nanocrystalline Technology Platform

- We have established a nanocrystalline technology platform and can design and prepare high-quality nanocrystals to meet customers' different needs.

- We hold advanced instruments and equipment and are also able to provide you with the preparation and characterization of nanocrystals that meet your quality requirements.

- Our technical team has a multidisciplinary background, extensive experience in nanocrystal customization and characterization, and can respond quickly to your nanocrystalline technology service requirements.

Custom Nanocrystal Development Services

With the help of our nanocrystalline technology, we can provide customers with personalized nanocrystal development and customization services to meet their specific needs. With a deep understanding of the unique properties of nanocrystals and their uses, we are committed to creating customized nanocrystal solutions to improve the clinical effectiveness and bioavailability of different pharmaceutical and biotech products.

Nanocrystal Development for Nanomedicine

CD Formulation specializes in nanocrystal development for nanomedicines, offering custom formulation development services powered by our cutting-edge nanocrystal technology. Our core technical team, backed by in-depth research on nanocrystal technology and its applications, develops nanocrystals for various uses, advancing their clinical and commercial potential.

Published Data

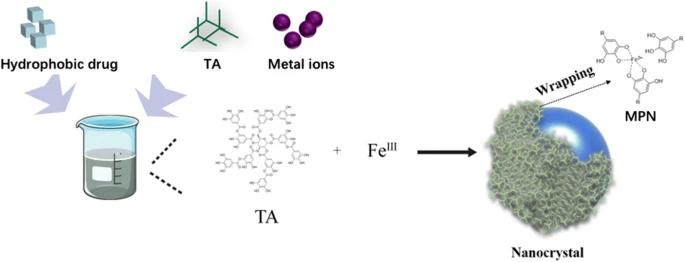

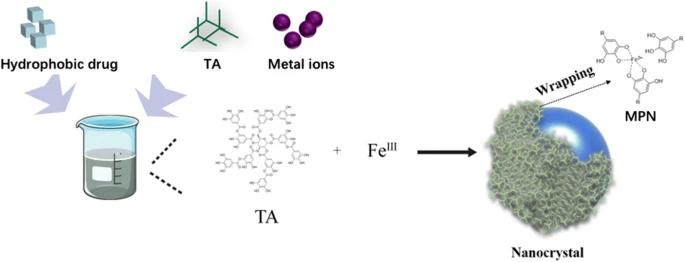

Technology: Nanocrystal production technology platform based on metal phenolic networks (MPNs)

Journal: AAPS PharmSciTech

IF: 3.3

Published: 2022

Results:

The authors report a nanocrystal production technology platform based on metal phenolic networks (MPNs). MPN-encapsulated nanocrystalline particles (MPN-NPs) were prepared by antisolvent precipitation using tannic acid and FeIII or AlIII as coupling agents and characterized by dynamic light scattering, transmission electron microscopy, UV-visible spectrophotometry, Fourier transform infrared spectroscopy, and X-ray powder diffraction. The authors focused on the in vitro release, cytotoxicity, and stability of MPN-NPs loaded with paclitaxel. The applicability of MPN as a nanocrystal stabilizer for other classical hydrophobic drugs was also investigated. The results suggest that MPNs may be a promising nanocrystal production platform to address the low solubility challenges associated with hydrophobic drugs.

Fig.3 Preparation of MPN-encapsulated nanocrystalline particles (MPN-NPs). (Feifei Huang, et al.2022)

Fig.3 Preparation of MPN-encapsulated nanocrystalline particles (MPN-NPs). (Feifei Huang, et al.2022)

Nanocrystals have great potential in the field of drug delivery and therapeutics. With our nanocrystal technology platform, CD Formulation reformulates poorly soluble drugs into new nanocrystals for clinical use, providing pharmaceutical companies with a clear competitive advantage. If you are interested in our nanocrystalline technology service, please kindly contact us.

References

- Maria Jarvis, Vinu Krishnan, Samir Mitragotri. Nanocrystals: A perspective on translational research and clinical studies. Bioengineering & Translational Medicine. 2019, (4):5-16.

- Feifei Huang, Xiaohong Jiang, Marwa A Sallam, et al. A Nanocrystal Platform Based on Metal-Phenolic Network Wrapping for Drug Solubilization. AAPS PharmSciTech. 2022, DOI: 10.1208/s12249-022-02220-0.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 Nanocrystallization of poorly soluble drugs improves physicochemical stability and drug bioavailability. (Maria Jarvis, et al. 2019)

Fig.1 Nanocrystallization of poorly soluble drugs improves physicochemical stability and drug bioavailability. (Maria Jarvis, et al. 2019) Fig.2 Different applications of nanocrystalline technology. (CD Formulation)

Fig.2 Different applications of nanocrystalline technology. (CD Formulation) Fig.3 Preparation of MPN-encapsulated nanocrystalline particles (MPN-NPs). (Feifei Huang, et al.2022)

Fig.3 Preparation of MPN-encapsulated nanocrystalline particles (MPN-NPs). (Feifei Huang, et al.2022)