Nanocrystal Development for Nanomedicine

Inquiry

Nanocrystal formulations are pure drug nanocolloidal dispersion systems. The drug itself is nanosized and does not require carrier materials to be loaded. The preparation process is simple, and the drug loading capacity is high. They are widely used clinically due to their unique advantages, such as anticancer drugs, antifungal drugs, hormonal drugs, anti-inflammatory drugs, etc. CD Formulation can provide our clients with nanocrystal development services for nanomedicines to meet the different requirements using our advanced nanocrystal technology. Our highly qualified nanoformulation development team can design and configure nanocrystal techniques, thus promoting research of nanocrystals for nanomedicine.

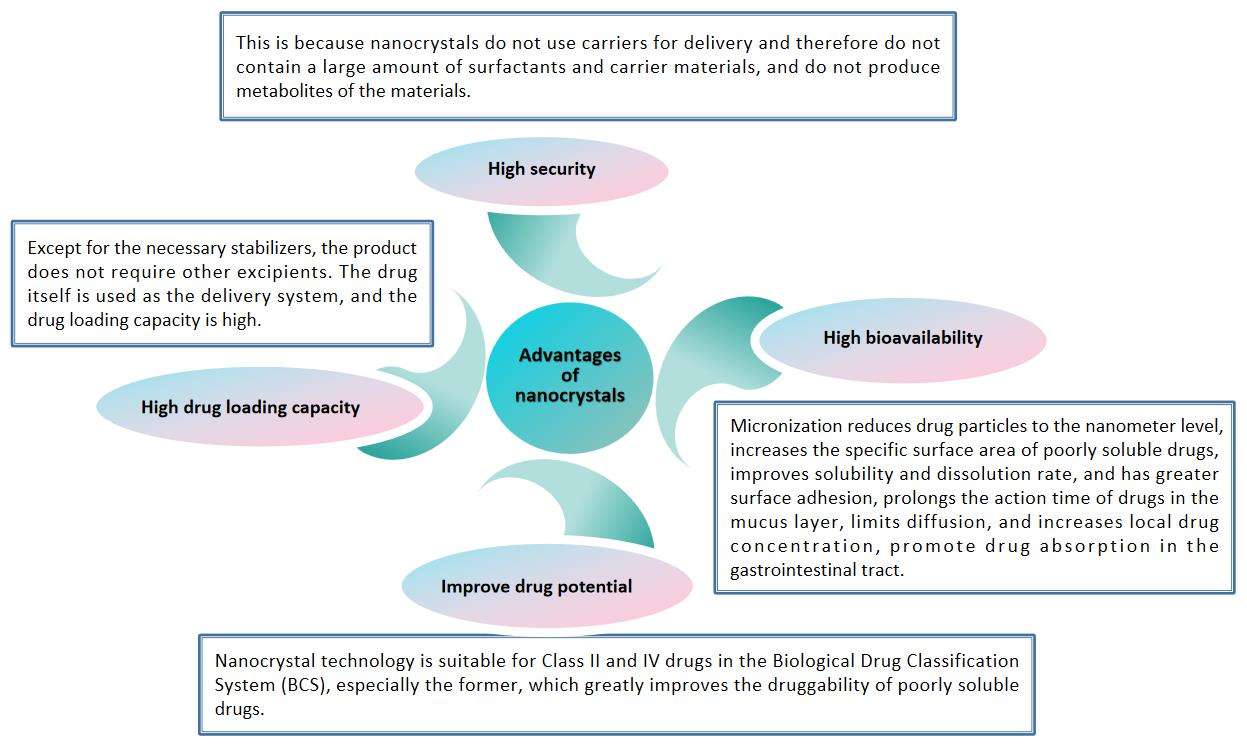

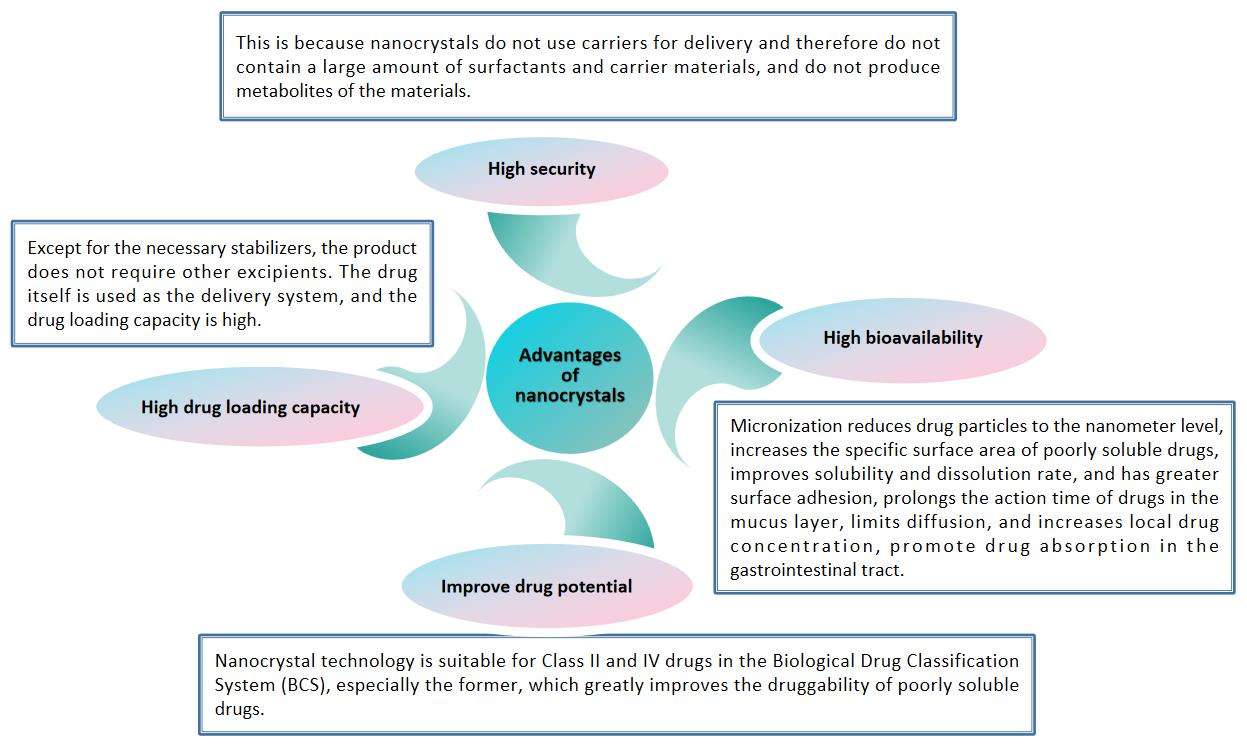

Advantages of Nanocrystals

Nanocrystal drugs are drug particles that are directly micronized to the nanometer level. They are carrier-free sub-micron colloidal dispersion systems. The particle size is generally 100- 1000 nm and contain only active pharmaceutical ingredients (API) and stabilizers.

Fig.1 Advantages of nanocrystals. (CD Formulation)

Fig.1 Advantages of nanocrystals. (CD Formulation)

Explore Our Nanocrystal Preparation Methods

Nanocrystals are usually prepared in the form of nanosuspensions, and the organic solvent is removed by rotary evaporation or centrifugation, and redispersible drug particles are obtained after freeze-drying. There are three basic methods for preparing drug nanocrystals, "top-down" method, the "bottom-up" method and the combination method. CD Formulation relies on our advanced design concept to use the following preparation methods for nanocrystals, such as, "top-down" method, and "bottom-up" method, and combination technologies.

Fig.2 Schematic representation of the main methods for the production of drug nanocrystals. (Flavia Fontana, et al. 2018)

Fig.2 Schematic representation of the main methods for the production of drug nanocrystals. (Flavia Fontana, et al. 2018)

"Top-Down" Method

"Top-down" method is to crush coarse drug particles through physical methods to obtain nano-sized particles. The main methods are high pressure homogenization (HPH) and wet media milling. The main advantages of these processes include the preparation of crystalline nanoparticles, flexibility in scale-up production and no harsh solvents.

High pressure homogenization (HPH): HPH method can be subdivided into piston gap homogenization and microfluidization.

Wet media milling: Wet media milling (pearl milling or bead milling) mainly disperses the drug in an aqueous phase containing a stabilizer to obtain a coarse suspension, which is then added to the grinder and relies on shear friction of the grinding beads to reduce the particle size of the drug.

Laserablation and crushing technology: Laserablation technology and crushing technology are new technologies for the preparation of nanocrystals. When using laser ablation technology, the drug is ejected from the solid under the action of the laser, forming nanocrystalline drugs in the surrounding liquid. When using laser fragmentation technology, the laser directly breaks the coarse suspension of drug particles to form nanocrystalline drugs.

"Bottom-Up" Method

"Bottom-up" method is to precipitate drug nanocrystals from a supersaturated solution of the drug, which can be subdivided into solvent-antisolvent precipitation method, supercritical fluid method, solvent evaporation and spray drying method.

Solvent-antisolvent precipitation: Solvent-antisolvent precipitation is to fully mix a drug solution (dissolved in an organic solvent that is miscible with water) and an antisolvent (water or an aqueous medium) to form an aqueous supersaturated solution, which nucleates the drug and forms a precipitate, eventually forming nanocrystals.

Supercritical fluid technology: Supercritical fluid technology dissolves drugs in supercritical fluid (SCF). When the supercritical liquid is atomized under reduced pressure through a nozzle with a smaller pore size, the supercritical fluid rapidly vaporizes and crystallizes the drug to form drug nanocrystals.

Solvent evaporation and spray drying: Solvent evaporation and spray drying is a technology that uses physical methods to remove the solvent in the drug solution and crystallize the drug to form nanocrystals.

Combination Method

The combined method combines the "top-down" method and "bottom-up" method and CD Formulation uses their respective advantages to prepare drug nanocrystals that are easy to produce industrially.

NanoEdge technology: NanoEdge technology is a combination of precipitation method and high-pressure homogenization method.

H69 technology (PharmaSol): H69 technology is a high-pressure cavitation precipitation-homogenization combination technology.

H96 technology: H96 technology is a combination of freeze-drying method and high-pressure homogenization method.

H42 technology: H42 technology is a combination of spray drying method and high-pressure homogenization method.

In addition to the above nanocrystal preparation methods, CD Formulation is exploring advanced nanocrystal preparation techniques, including PLH, CT, ARTcrystals, and Ultrasonic methods combined with antisolvent precipitation technology, to support researchers.

Our Analytical Capabilities for Nanocrystals

After obtaining nanocrystal products, we also provide nanocrystal characterization and performance evaluation services according to the different needs of customers. The purpose of characterization is to understand the properties of the sample, such as size, morphology and crystal form. Based on this, the performance of different quality characteristics of the product can be quantitatively controlled, thereby achieving product quality controllability. The evaluation is to obtain the performance indicators (stability, cytotoxicity, dissolution rate) of nanocrystals to explore more effective drug delivery strategies. CD Formulation can provide you with the following characterization and evaluation services of nanocrystals including:

- Particle Size and Distribution

- Morphological Characterization

- Structural Characterization

- Surface Property (Zeta Potential)

- Stability

- Cytotoxicity

- In Vitro Dissolution

- In Vivo Dissolution

Why Choose Us to Develop Nanocrystals?

- We have built a world-heading nanocrystal technology platform, this technology can reduce drug particle size to the nanometer level, which can effectively improve the solubility and dissolution rate of poorly soluble drugs, reduce administration volume, and reduce toxic and side effects, thereby improving bioavailability and clinical efficacy.

- Based on our nanocrystal technology platform, our professional team has made breakthroughs in nanocrystal preparation technology and can customize high-quality nanocrystals that meet the requirements of customers according to their different requirements.

- We also continue to improve our nanocrystal preparation methods, including HPH, wet media milling, solvent-antisolvent precipitation, supercritical fluid, solvent evaporation, spray drying, etc. to make our nanocrystal preparation process reproducible and easy for further industrialization.

- We can offer characterization and evaluation services for nanocrystals, such as particle size and distribution, morphology, zeta potential, stability, in vitro and in vivo dissolution, etc.

Published Data

Technology: Antisolvent precipitation method for hybrid nanocrystals

Journal: Advanced Drug Delivery Reviews

IF: 16.1

Published: 2019

Results:

Nanocrystal technology enables simultaneous therapy and bioimaging and has become widely accepted for studying pharmacokinetics and solubility of nanocrystals in vivo. Nanocrystals also have the advantage of long-term durability in interacting with biological tissues and cells in the body. The authors introduce hybrid nanocrystal technology, including theoretical concepts, preparation methods and applications. The authors also discuss recent developments in self-differentiating hybrid nanocrystals utilizing environmentally sensitive probes, which provide necessary therapeutic strategies for the development of nanocrystal-based drug therapy systems.

CD Formulation has been leading the way in nanocrystal development for many years. If you are interested in our services, please do not hesitate to contact us for in-depth discussion and communication.

References

- Flavia Fontana, Patrícia Figueiredo, Pei Zhang, et al. Production of pure drug nanocrystals and nano co-crystals by confinement methods. Advanced Drug Delivery Reviews. 2018, 131, 3-21.

- Yi Lu, Yongjiu Lv, Tonglei Li. Hybrid drug nanocrystals. Advanced Drug Delivery Reviews. 2019,143: 115-133.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 Advantages of nanocrystals. (CD Formulation)

Fig.1 Advantages of nanocrystals. (CD Formulation) Fig.2 Schematic representation of the main methods for the production of drug nanocrystals. (Flavia Fontana, et al. 2018)

Fig.2 Schematic representation of the main methods for the production of drug nanocrystals. (Flavia Fontana, et al. 2018)