Microparticle Drug Delivery System for Nanoformulations

Inquiry

Microparticle systems exhibit improved therapeutic and diagnostic characteristics and can be produced using various materials, including polymers. These systems have demonstrated efficacy in enhancing the physical and chemical attributes, as well as the biological functionality, of active substances. CD Formulation provides development services for microparticle drug delivery systems, specifically tailored for nanoformulations. We harness our advanced microparticle technology platform to create customized solutions that meet the unique needs of our clients, focusing on the engineering and design of the delivery systems.

Advantages of Microparticle Drug Delivery Systems

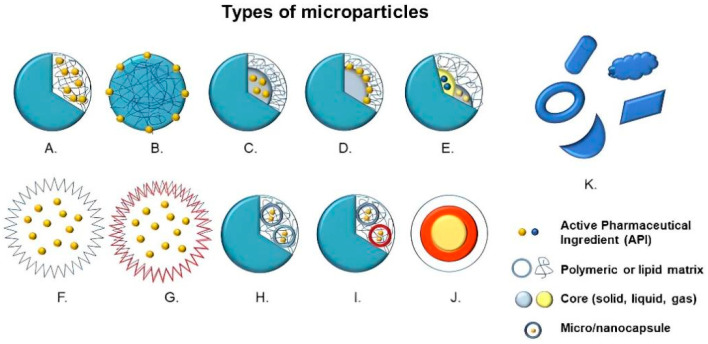

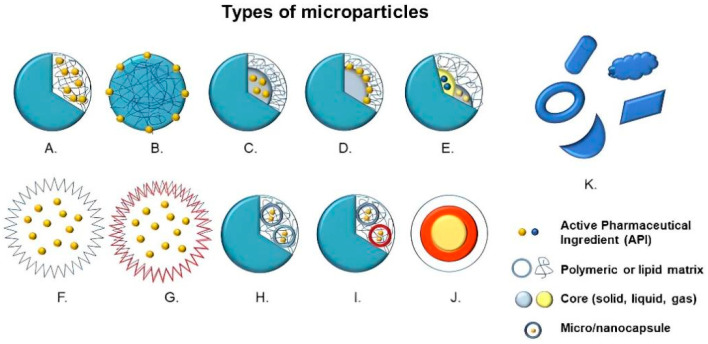

Microparticle systems, encompassing microparticles, microspheres, and microcapsules within the size range of 1-1000 µm, serve as prevalent drug delivery platforms. These systems can be categorized into two main types based on their structural composition: microspheres and microcapsules. Microspheres exhibit a homogenous dispersion or dissolution of active compounds and raw materials, while microcapsules feature a membrane shell encapsulating a solid, liquid, or gas core where the active ingredients are contained.

Fig.1 Types of microparticles: A. Microsphere with entrapped active pharmaceutical ingredient (API), B. Microsphere with adsorbed API, C. Microcapsule with entrapped API, D. Microcapsule with adsorbed API, E. Multinucleated microcapsule, F. Hollow microparticle, G. Hollow microparticle with several layers, H. Microparticle containing microcapsules, I. Microparticles containing multinucleated microcapsules, J. Multilayer microparticles and K. Microparticles with irregular shapes. (Rita Y. P. da Silva, et al. 2023)

Fig.1 Types of microparticles: A. Microsphere with entrapped active pharmaceutical ingredient (API), B. Microsphere with adsorbed API, C. Microcapsule with entrapped API, D. Microcapsule with adsorbed API, E. Multinucleated microcapsule, F. Hollow microparticle, G. Hollow microparticle with several layers, H. Microparticle containing microcapsules, I. Microparticles containing multinucleated microcapsules, J. Multilayer microparticles and K. Microparticles with irregular shapes. (Rita Y. P. da Silva, et al. 2023)

Microparticles, especially microspheres and microcapsules, are very popular in the field of drug design as a new drug delivery system. Microparticles have the following advantages as drug delivery systems.

- Microparticles can prolong the therapeutic effects of nanoformulations.

- The frequency of nanoformulation can be reduced, thereby greatly improving patient compliance.

- Modulating drug absorption in a more reproducible manner significantly improves clinical efficacy.

- It is easy to inject and can be used in various fields including long-acting injection.

- Fewer side effects.

- Encapsulation and delivery of microparticles can not only mitigate dose dumping but also enhance environmental stability.

- Microparticles are more biocompatible.

Drug Release Mechanism of Microparticles

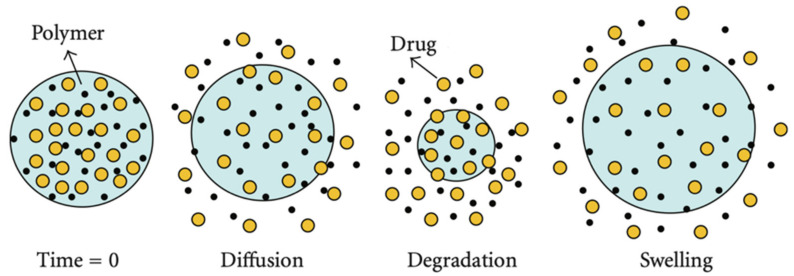

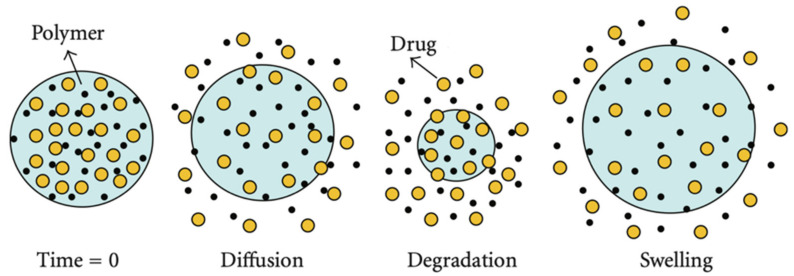

There are three different mechanisms for drug release from polymer microparticle systems, such as release through diffusion from the particle surface, release through particle erosion caused by polymer degradation, and release through swelling of the polymer matrix.

Diffusion

Diffusion is the process by which drug molecules dissolve in the body fluids surrounding or within the microparticles and migrate out of the microparticles.

Erosion

Erosion begins when dissolved polymer particulate degradation products are able to diffuse into the release area.

Swelling

PLGA systems with flexible polymer chains tend to absorb large amounts of water when in vivo and swell to increase internal pressure and porosity, allowing drug molecules to diffuse out of the swollen network.

Fig.2 Drug release mechanisms of PLA microspheres. (Antonios Vlachopoulos, et al. 2022)

Fig.2 Drug release mechanisms of PLA microspheres. (Antonios Vlachopoulos, et al. 2022)

Our Process for Developing Microparticle Drug Delivery Systems

CD Formulation can perform a feasibility study to assess the compatibility of microparticle drug delivery systems with specific requirements and characteristics. This study involves pre-formulation investigations, development of microparticle formulations, characterization and analysis of microparticles to verify the final nanoformulation, laboratory scale-up, and commercial scale production.

Pre-formulation Studies of Microparticle Formulations

The purpose of pre-formulation studies is to explore the best way to develop and produce microparticles.

Microparticle Formulation Development

We prepare microparticles using appropriate manufacturing techniques and perform characterization and analysis of microparticles to confirm initial formulation feasibility.

Laboratory Scale-up and Commercial Production

We use laboratory scale-up to further confirm that the formulation process and microparticle quality meet the expected requirements. Once the final formulation is confirmed, the microparticle drug delivery system is ready to start commercial-scale production.

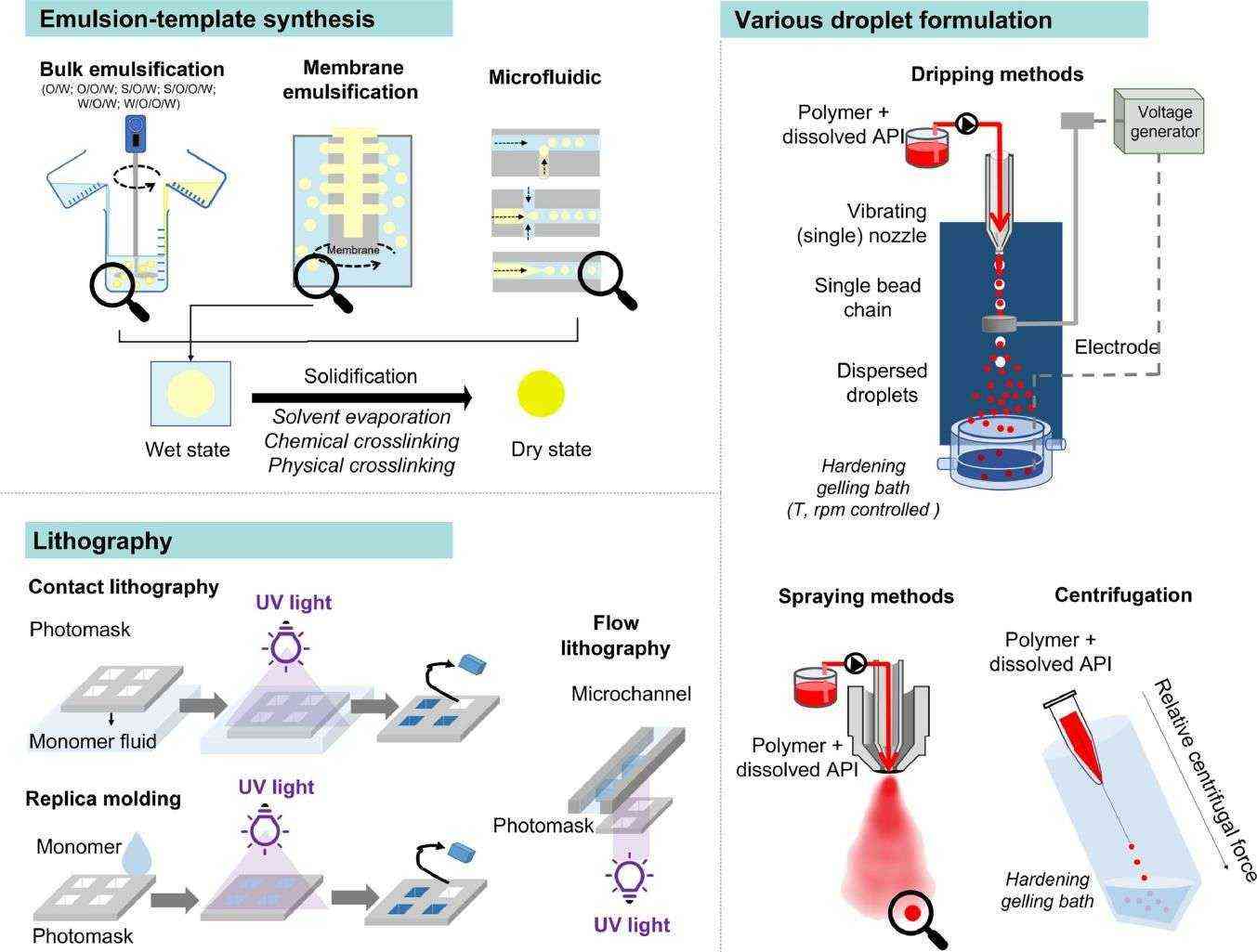

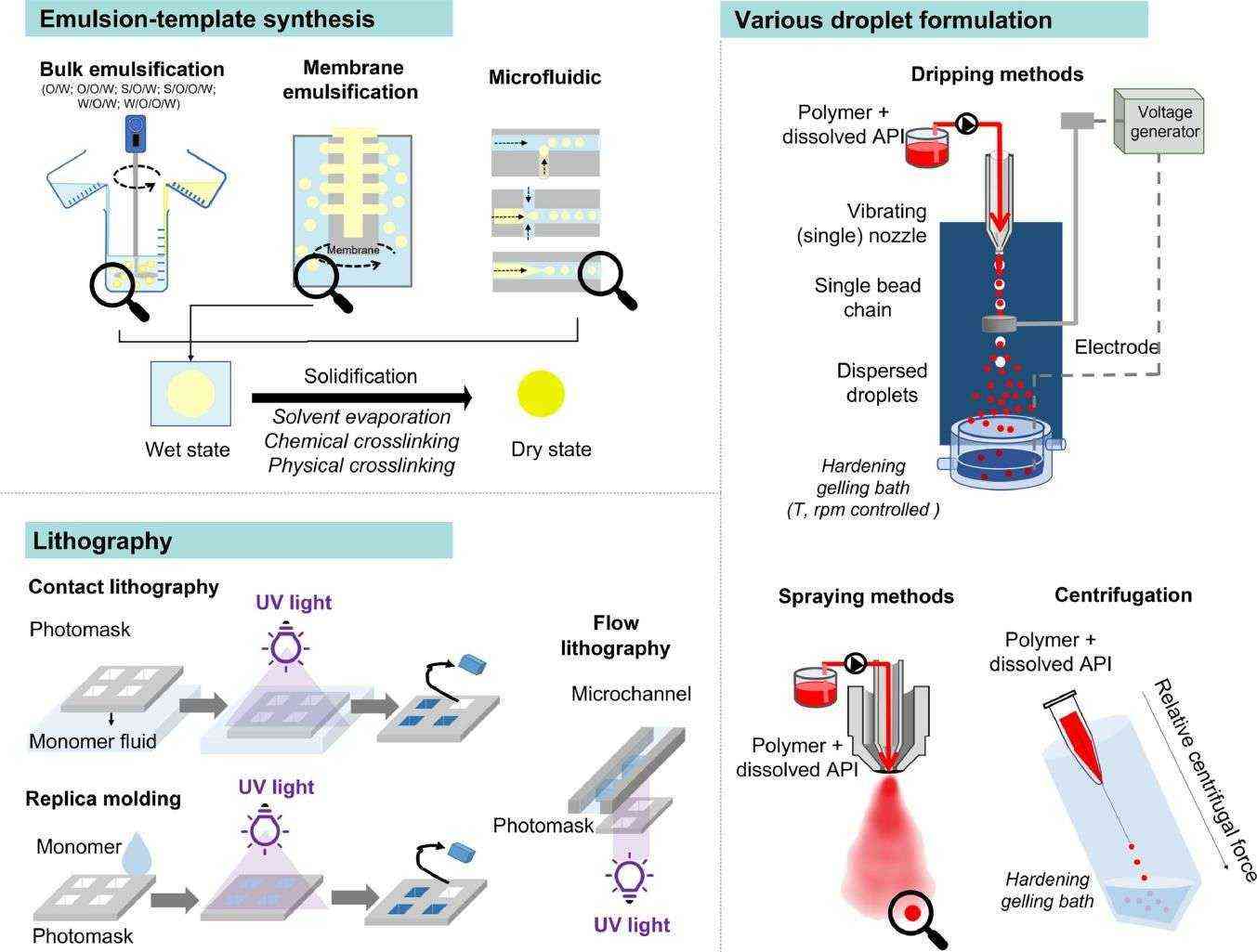

Our Techniques for Developing Microparticle Drug Delivery Systems

Microparticles can not only improve the bioavailability of drugs and minimize the toxic side effects of drugs in drug delivery systems, but also increase the solubility of poorly soluble or hydrophobic drugs by increasing their surface area. Therefore, microparticles are widely used in drug delivery systems. CD Formulation relies on our advanced design concept and microparticle technology platform to develop and construct microparticle drug delivery systems. We have also explored multiple techniques for microparticle drug delivery systems, such as emulsion-template synthesis, various droplet formulation and lithography.

Emulsion-template Syntheses to Produce Microspheres and Microcapsules

Bulk Emulsification: This method is used to prepare hydrophilic or hydrophobic microspheres capable of carrying small to large drug molecules (peptides, proteins).

Membrane Emulsification: In this method, droplets are produced by a drop-by-drop mechanism. The liquid part that forms the droplets can be a solution or an emulsion. We squeeze them through a microporous membrane to form a simple or complex emulsion.

Microfluidics: In this method, emulsion droplets are formed at the intersection of two or more immiscible liquids in microchannels. Microfluidics-based emulsion template synthesis produces uniform emulsion droplets with controllable size, shape, composition and structure.

Droplet Formulation

Droplets can be formed by spraying, dripping, or centrifugal force.

Lithography

In the photolithography-based approach, we use molds or photomasks to produce microparticles of different shapes and sizes through UV-initialized photopolymerization.

Fig.3 Commonly used processes to produce polymer-based microparticles. (Nikolett Kállai-Szabó, et al. 2024)

Fig.3 Commonly used processes to produce polymer-based microparticles. (Nikolett Kállai-Szabó, et al. 2024)

Highlights of Our Microparticle Drug Delivery System Development

- Depending on our innovative microparticle technology platform, our team has accumulated rich experience in the construction of microparticles as a nanodrug delivery system.

- We have extensive expertise in encapsulation techniques and fabrication technology for microparticles. We are able to customize high-quality microparticles and perform characterization of microparticles for our customers.

- We are also committed to exploring and researching the construction techniques for microparticle drug delivery systems, including emulsion-template synthesis, droplet formulation and lithography.

Custom Microparticle Development Services

We have conducted in-depth research on microparticle formulation development. With our advanced microparticle drug delivery system, we provide customized formulation development services for microparticles. Our team has conducted in-depth research on the drug release mechanism of microparticles and microparticle drug delivery technology and is able to develop microparticles for different purposes to help clinical transformation and commercial production and application of microparticles.

Microparticle Development for Nanomedicine

Using our mature microparticle delivery system, CD Formulation offers customized development services tailored to individual customer needs. Our in-depth research into microparticle characteristics, drug release mechanisms, and specific delivery technologies enables us to provide personalized solutions that enhance the bioavailability, clinical safety, and efficacy of various microparticle formulations.

Published Data

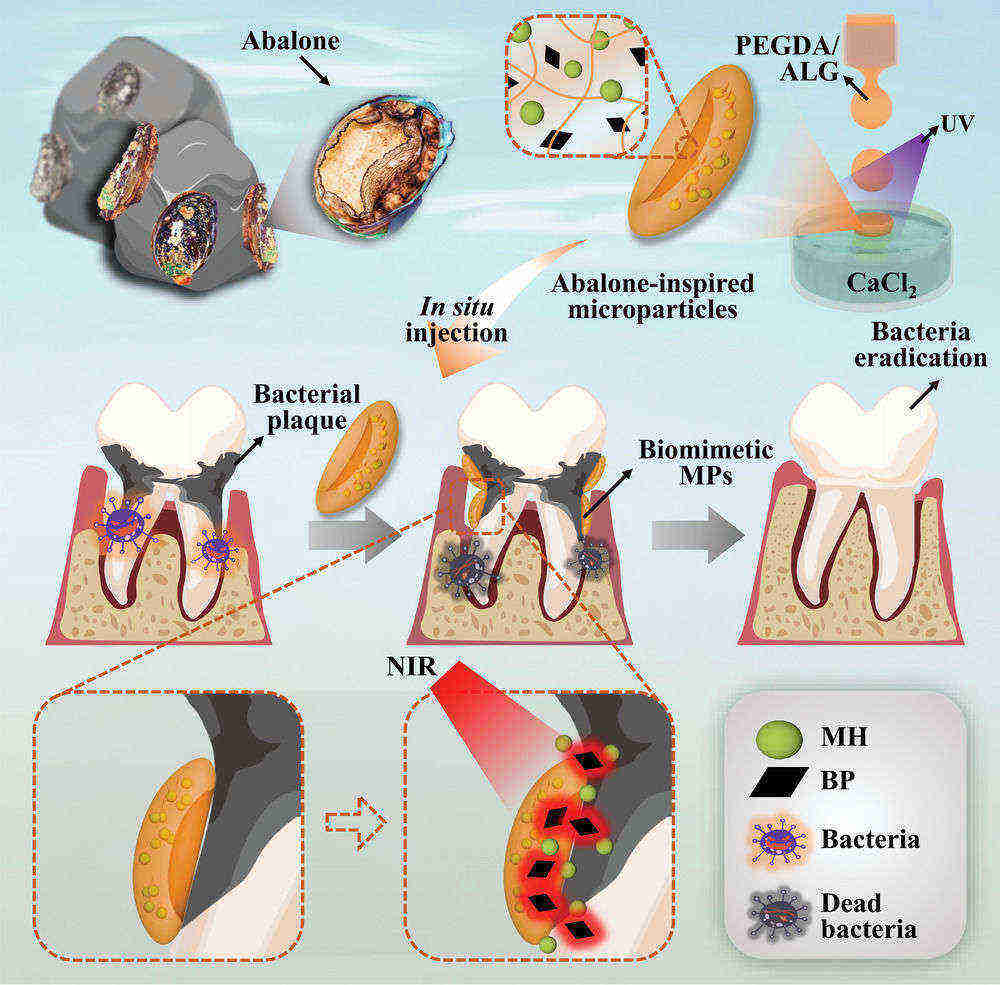

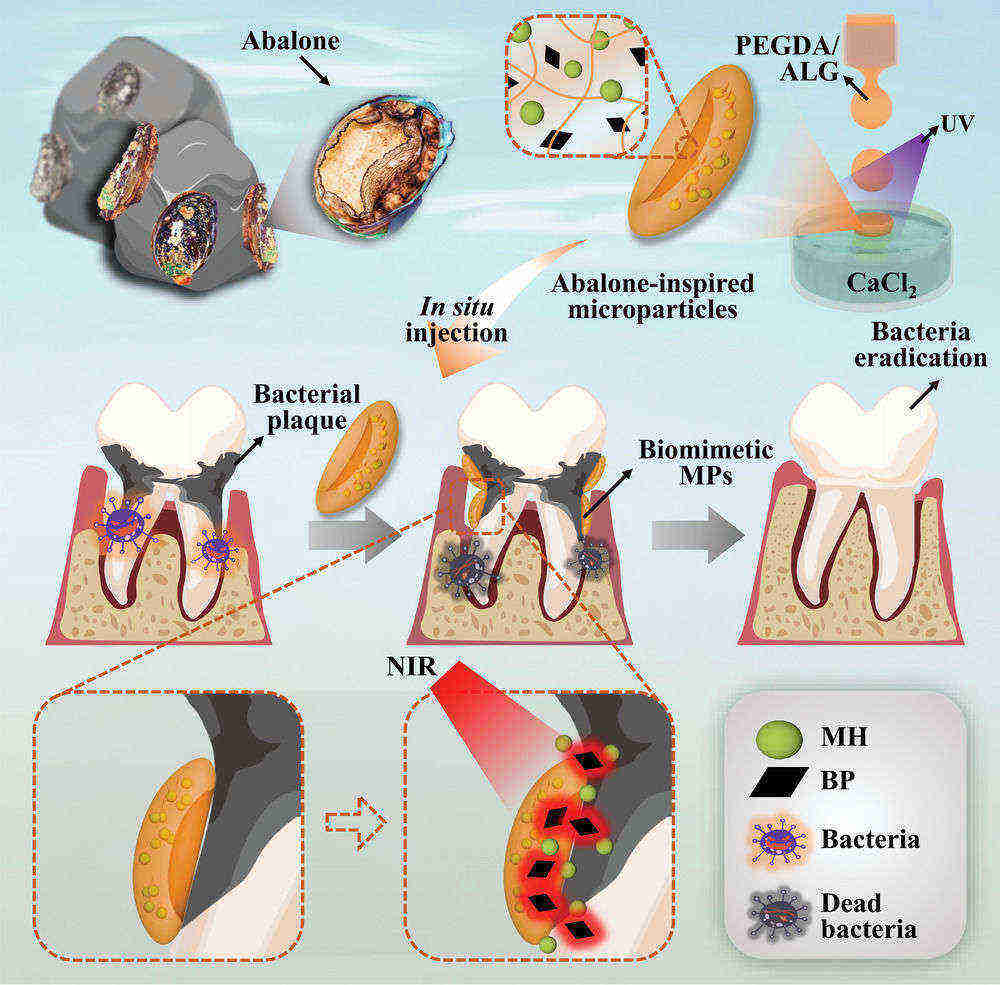

Technology: Novel adhesive and photo-responsive microparticle delivery system

Journal: Advanced Science

IF: 15.1

Published: 2022

Results:

The authors developed a novel adhesive and light-responsive microparticle delivery system to treat periodontitis via microfluidic electrospray technology. The microparticles are produced by rapid ionic cross-linking of sodium alginate and photocuring of poly (ethylene glycol) diacrylate by twisting microfluidic droplets during high-speed dripping of calcium chloride solution. It has been proven from living periodontitis that abalone particles have strong adhesion and can control the release of drugs on teeth, thus having outstanding antibacterial effects on periodontitis.

Fig.4 The graphical illustration of the abalone-inspired microparticles' design, preparation process, and application. (Chuanhui Song, et al. 2022)

Fig.4 The graphical illustration of the abalone-inspired microparticles' design, preparation process, and application. (Chuanhui Song, et al. 2022)

Microparticle drug delivery system can effectively protect the encapsulated active ingredients from degradation, accurately control the release rate of the incorporated drugs, and facilitate administration. As your most loyal partner, CD Formulation can respond immediately to your needs for microparticle drug delivery system services and offer reasonable and personalized service proposals for you. If you are interested in our microparticle drug delivery system services, please contact us.

References

- Rita Y. P. da Silva, Danielle L. B. de Menezes, Verônica da S. Oliveira, et al. Microparticles in the Development and Improvement of Pharmaceutical Formulations: An Analysis of In Vitro and In Vivo Studies. Int J Mol Sci. 2023,24(6): 5441.

- Antonios Vlachopoulos, Georgia Karlioti, Evangelia Balla, et al. Poly(Lactic Acid)-Based Microparticles for Drug Delivery Applications: An Overview of Recent Advances. Pharmaceutics. 2022,14(2):359.

- Nikolett Kállai-Szabó, Dóra Farkas, Miléna Lengyel, et al. Microparticles and multi-unit systems for advanced drug delivery. European Journal of Pharmaceutical Sciences. 2024,194,106704.

- Chuanhui Song, Danqing Huang, Cheng Zhao, et al. Abalone-Inspired Adhesive and Photo-Responsive Microparticle Delivery Systems for Periodontal Drug Therapy. Advanced Science. 2022,9, 2202829.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 Types of microparticles: A. Microsphere with entrapped active pharmaceutical ingredient (API), B. Microsphere with adsorbed API, C. Microcapsule with entrapped API, D. Microcapsule with adsorbed API, E. Multinucleated microcapsule, F. Hollow microparticle, G. Hollow microparticle with several layers, H. Microparticle containing microcapsules, I. Microparticles containing multinucleated microcapsules, J. Multilayer microparticles and K. Microparticles with irregular shapes. (Rita Y. P. da Silva, et al. 2023)

Fig.1 Types of microparticles: A. Microsphere with entrapped active pharmaceutical ingredient (API), B. Microsphere with adsorbed API, C. Microcapsule with entrapped API, D. Microcapsule with adsorbed API, E. Multinucleated microcapsule, F. Hollow microparticle, G. Hollow microparticle with several layers, H. Microparticle containing microcapsules, I. Microparticles containing multinucleated microcapsules, J. Multilayer microparticles and K. Microparticles with irregular shapes. (Rita Y. P. da Silva, et al. 2023) Fig.2 Drug release mechanisms of PLA microspheres. (Antonios Vlachopoulos, et al. 2022)

Fig.2 Drug release mechanisms of PLA microspheres. (Antonios Vlachopoulos, et al. 2022) Fig.3 Commonly used processes to produce polymer-based microparticles. (Nikolett Kállai-Szabó, et al. 2024)

Fig.3 Commonly used processes to produce polymer-based microparticles. (Nikolett Kállai-Szabó, et al. 2024) Fig.4 The graphical illustration of the abalone-inspired microparticles' design, preparation process, and application. (Chuanhui Song, et al. 2022)

Fig.4 The graphical illustration of the abalone-inspired microparticles' design, preparation process, and application. (Chuanhui Song, et al. 2022)