Microparticle Development for Nanomedicine

Inquiry

Microparticle formulations refer to solid, liquid, semi-solid or gaseous pharmaceutical formulations composed of particles with a certain particle size made through a certain dispersion and encapsulation technology with drugs or appropriate carriers. CD Formulation has dedicated itself to developing particulate drug delivery systems through microencapsulation methods for a long time. They have been helping researchers and pharmaceutical companies from different countries in creating microparticles for nanomedicines. These systems are commonly utilized to prolong drug delivery duration, increase bioavailability, improve stability, and direct drugs to particular locations.

Benefits of Microparticles in Drug Delivery System

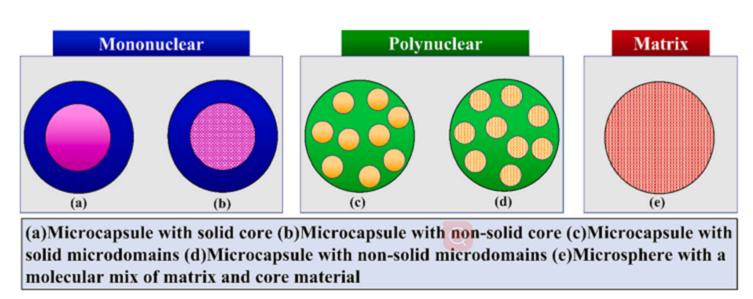

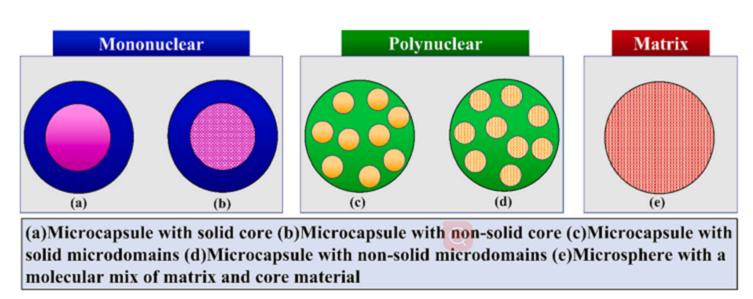

Microparticles are particles with a diameter of 1-1000 μm. Depending on their internal structure, particulate systems can be classified into microspheres and microcapsules.

Fig.1 Schematic representation of different structures of microparticles. (Subrat Kumar Panigrahi, et al. 2024)

Fig.1 Schematic representation of different structures of microparticles. (Subrat Kumar Panigrahi, et al. 2024)

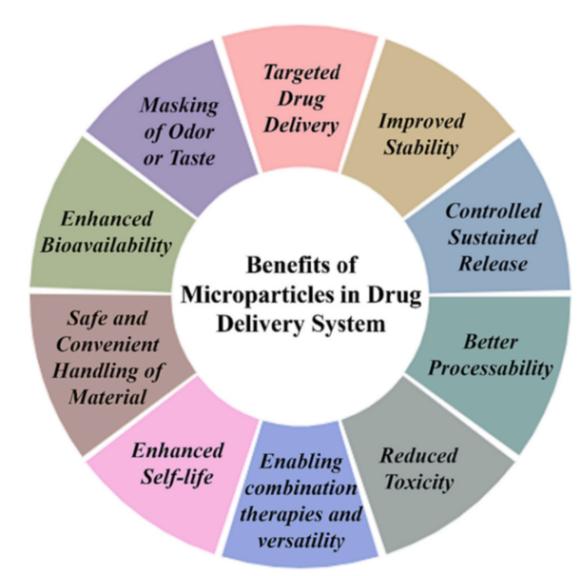

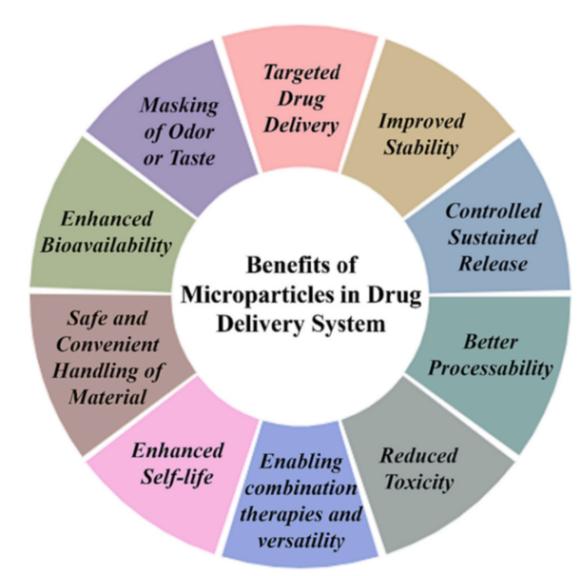

Microparticles have higher efficacy, lower toxicity, and better stability. Microparticles can provide a multifunctional drug delivery and tissue engineering platform with the advantages of facilitating the delivery of poorly soluble drugs, long-term controlled/sustained release, maintaining the stability of active compounds in the body, and ensuring the efficacy of these compounds until their target release.

Fig.2 Benefits of microparticles in drug delivery system. (Subrat Kumar Panigrahi, et al. 2024)

Fig.2 Benefits of microparticles in drug delivery system. (Subrat Kumar Panigrahi, et al. 2024)

Our Microparticle Development Services

We are committed to the microparticle development based on our advanced design concept, instruments, and equipment many years. Our solutions of microparticle development include selection of core and encapsulating materials, synthesis of microparticles by microencapsulation techniques.

Selection of Core and Encapsulating Materials

Core materials: Depending on our client's needs and process requirements, core materials might be solid particles, liquid droplets, dispersions, or sometimes gas molecules, etc.

Encapsulating materials: Encapsulation materials are required to meet specific dosage formulation or product requirements (such as stability of the formulation during particle processing, biocompatibility, etc.), they can form a coherent film around the core material, and they are chemically compatible with the core material and do not react.

Synthesis of Microparticles

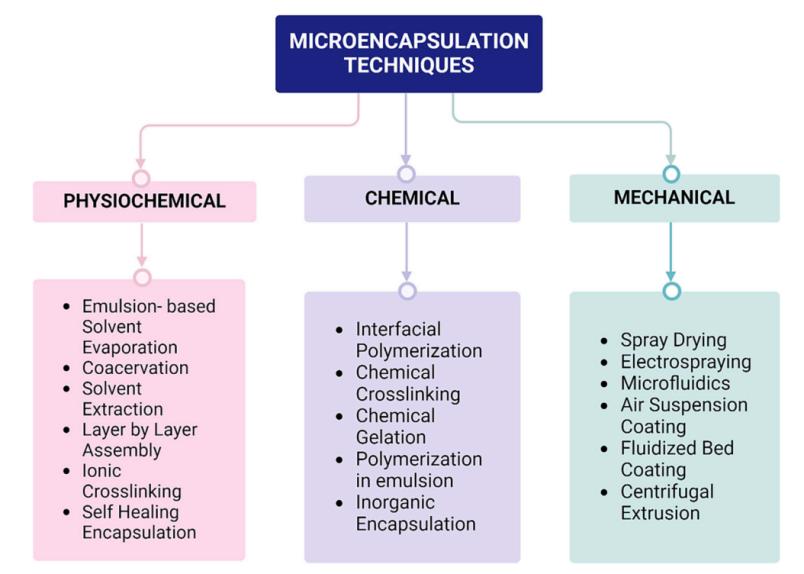

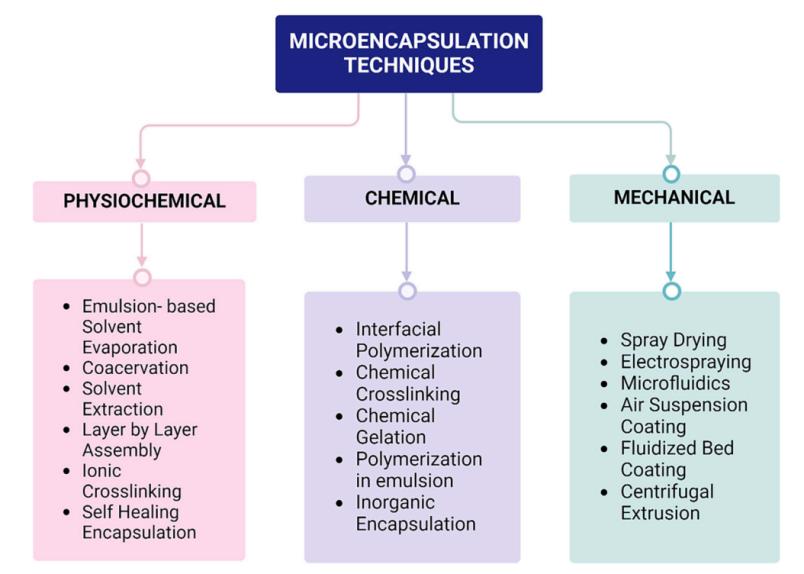

The synthesis process of microparticles is called microencapsulation. It encapsulates the core material in a protective shell or membrane, producing micron-sized particles. We can synthesis microparticles by the following microencapsulation techniques based on different properties of raw materials including physicochemical, chemical, or mechanical processes, being further subclassified into physical-chemical and physicalemechanical processes.

Fig.3 Classification of different microencapsulation techniques. (Subrat Kumar Panigrahi, et al. 2024)

Fig.3 Classification of different microencapsulation techniques. (Subrat Kumar Panigrahi, et al. 2024)

We have developed a variety of methods over the years, such as electrospraying, spray drying, microfluidics, solvent evaporation, gelation, coacervation, etc.

Electrospraying provides precise control of particle size and is suitable for use with fine biomolecules. In this method, a high voltage is applied to a polymer solution to create a charged jet. The jet breaks up into droplets and the solvent evaporates, forming fine particles.

Spray drying involves atomizing a liquid feed solution into fine droplets in a drying chamber where the solvent rapidly evaporates, leaving behind solid particles.

Microfluidic technology is a process in which immiscible fluids collide with each other through the interaction of flow shear force and surface tension in microchannels with a scale of more than ten micrometers and are finally divided into discrete micron-sized droplets.

CD Formulation uses solvent evaporation or diffusion to produce particles. This manufacturing method often utilizes the dissolution and assembly of organic compounds in volatile solvents to prepare microparticles.

Gelation utilizes a gel system formed by cross-linking to construct a sustained-release carrier, and the solvent in the volatile polymer solidifies to form microparticles.

Coacervation is when two immiscible polymers or polymers and non-polymers interact to form a coacervate phase, resulting in the formation of particles or microcapsules within this phase due to increased polymer concentration or separation of the polymer-rich phase from the continuous phase.

Our Analytical Capabilities for Microparticles

After synthesizing particles through different encapsulation technologies, we can also characterize the shape, size, size distribution, elemental composition, density, porosity, and crystallinity of the particles through SEM, EDX, specific gravity analysis, BET surface area analysis and XRD technology to meet the needs of our customers' quality requirements for particulate prototypes.

- Shape

- Particle size and Distribution

- Elemental Composition

- Density

- Drug Loading

- Targeting Evaluation

- Porosity

- Crystallinity

Why Choose Us to Develop Microparticles?

- Our R&D team has a multidisciplinary background, including R&D backgrounds in nanomedicine, pharmacy, biology, materials science, etc. They have active innovative thinking, extensive biological expertise, and experimental research experience. They are committed to exploring and researching microparticle development including the selection of core and encapsulating materials, and the synthesis of microparticles.

- Based on our variety of advanced instruments and equipment, we have developed different microparticle fabrication methods, such as electrospraying, spray drying, microfluidics, solvent evaporation, gelation, coacervation, etc.

- We also provide customers with quality analysis and evaluation for microparticles, including particle size and distribution, shape, porosity, density, in vitro drug release, etc.

Published Data

Technology: microencapsulation techniques for the synthesis of microparticles

Journal: Advances in Colloid and Interface Science

IF: 15.6

Published: 2024

Results:

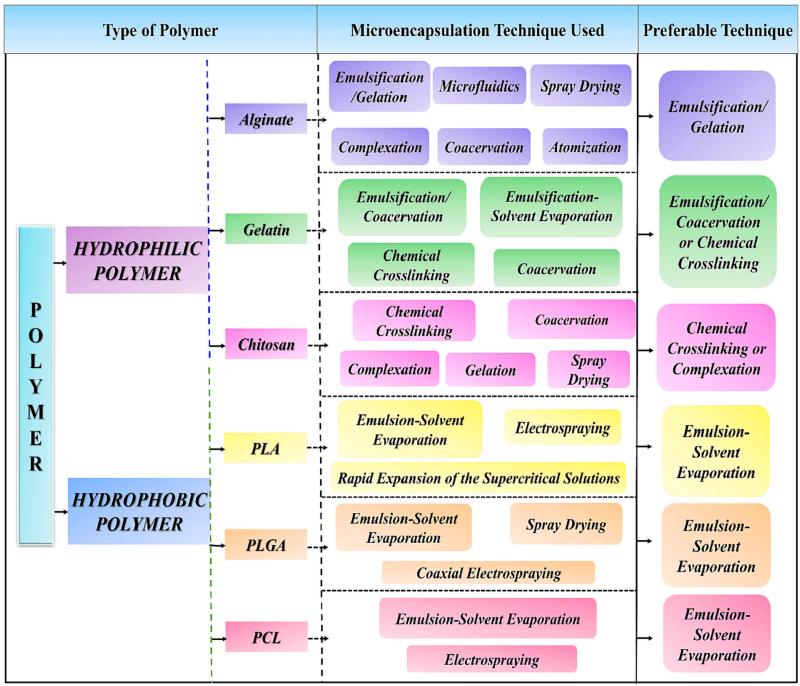

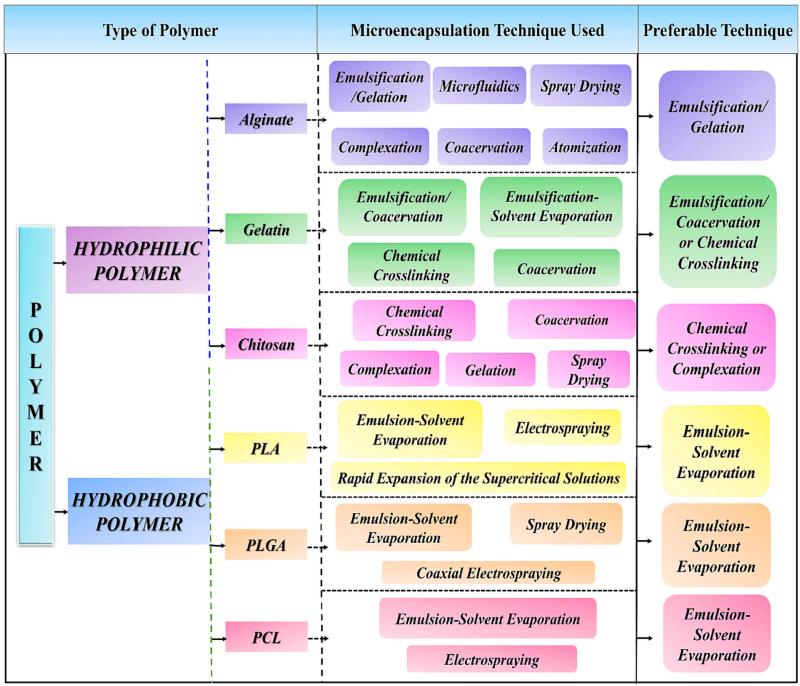

The authors review different microencapsulation techniques for the synthesis of microparticles and the factors affecting microencapsulation, which are critical to realizing the full potential of microparticle synthesis. The authors also summarized microencapsulation technologies for the synthesis of different polymer particles. This review provides necessary technical support for the possibility of optimizing microencapsulation technology to produce microparticles with the characteristics and properties required for different applications.

Here are different microencapsulation techniques for the synthesis of microparticles shown in this article:

Fig.4 Schematic representation of the synthesis of microparticles from different hydrophilic and hydrophobic polymers. (Subrat Kumar Panigrahi, et al. 2024)

Fig.4 Schematic representation of the synthesis of microparticles from different hydrophilic and hydrophobic polymers. (Subrat Kumar Panigrahi, et al. 2024)

CD Formulation, as your truthful partner, has always been at the forefront of microparticle development, covering microparticle fabrication and characterization. If you have any need for our services, please contact us by phone or email and we will reply to you within three working days.

References

- Subrat Kumar Panigrahi, Sougat Das, Saptarshi Majumdar. Unveiling the potentials of hydrophilic and hydrophobic polymers in microparticle systems: Opportunities and challenges in processing techniques. Advances in Colloid and Interface Science. 2024, 326,103121.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 Schematic representation of different structures of microparticles. (Subrat Kumar Panigrahi, et al. 2024)

Fig.1 Schematic representation of different structures of microparticles. (Subrat Kumar Panigrahi, et al. 2024) Fig.2 Benefits of microparticles in drug delivery system. (Subrat Kumar Panigrahi, et al. 2024)

Fig.2 Benefits of microparticles in drug delivery system. (Subrat Kumar Panigrahi, et al. 2024) Fig.3 Classification of different microencapsulation techniques. (Subrat Kumar Panigrahi, et al. 2024)

Fig.3 Classification of different microencapsulation techniques. (Subrat Kumar Panigrahi, et al. 2024) Fig.4 Schematic representation of the synthesis of microparticles from different hydrophilic and hydrophobic polymers. (Subrat Kumar Panigrahi, et al. 2024)

Fig.4 Schematic representation of the synthesis of microparticles from different hydrophilic and hydrophobic polymers. (Subrat Kumar Panigrahi, et al. 2024)