Liposome Formulation Process Development

Inquiry

CD Formulation possesses extensive knowledge and expertise in liposome formulation development, offering valuable assistance throughout the process. We provide comprehensive services for drug delivery, biomedical applications, cosmetics, and food industries. Our cutting-edge technology center is equipped with advanced equipment and highly skilled professionals to ensure efficient screening and optimization procedures that yield top-notch outcomes. Our team comprises seasoned experts with profound understanding and practical experience in liposome development. Whether you need help with liposome preparation, drug delivery systems, biomedical applications or advancements in cosmetics and food industry, we are committed to providing utmost professionalism through our guidance and support.

Why Liposome Formulation Process Development Service Needed?

In order to achieve optimal clinical outcomes of liposome preparations, it is imperative to thoroughly investigate the preparation process. Even slight modifications in the drug preparation procedure can significantly impact the safety and efficacy of liposome formulations. Various techniques such as membrane hydration, solvent injection, emulsion formation, active drug delivery, and microfluidic technology are employed for liposome production to generate drugs with distinct particle sizes, structures, and functionalities. The production process involves multiple steps wherein lipid hydration, membrane extrusion, washing and filtering necessitate extensive expertise and meticulous process control. Optimization at any stage can enhance overall operational efficiency by streamlining and fortifying the entire process.

What Can We Do About Liposome Formulation Process Development?

The following services are offered for the development of liposome processes.

This service involves the evaluation of various factors, including the ratio of drugs to lipids, method of preparation, technique for loading, type and proportion of buffer used, dosage of active pharmaceutical ingredient (API), and ratio of water to oil.

The service includes the following types but is not limited to optimization of liposome ratio parameters (the type and proportion of these materials have a great impact on their performance and function), and adjustment of liposome structure (size, shape, distribution, etc., jointly determine the structure of the liposome and directly affect the release and delivery of drugs); optimization of preparation process parameters.

Our Platform for Liposome Formulation Process Development

| Technology Platform |

Specifics |

Extrusion Technique for Liposomes

|

The extrusion process primarily involves three factors: the temperature and pressure of extrusion, as well as the selection of polycarbonate film. |

High pressure homogenizer

|

The technology involves dissolving lipid material in an aqueous phase with a surfactant, followed by high-pressure homogenization to create small and uniformly distributed liposomes. This process ensures consistent repeatability and enables large-scale production of stable liposomes with advantages such as small particle size, high encapsulation rate, and facilitating continuous production. |

Lyophilization Technology

|

The successful preparation of lyophilized liposomes depends on encapsulation efficiency, particle size, and various factors including liposome wall material, drug type, freeze-drying protective agent, and duration. Lyophilized liposome powder offers superior storage stability compared to liquid-placed liposomes. |

Our technologies are as following.

| Technology Platform |

Specifics |

| Active Drug Loading Technology |

The transmembrane gradient (pH/ion), incubation temperature and duration, drug-lipid ratio, logarithm of the drug-oil water partition coefficient (logP), and acidity coefficient (pKa) all serve as influential factors in active drug delivery. |

| Microfluidics Technology |

Variable particle size (from tens of nanometers to hundreds of microns) and narrow particle size distribution can be achieved by adjusting the flow ratio of the aqueous and lipid phases, liquid channel length, temperature, mixing conditions and lipid concentration. |

| Spray Freeze Drying Technology |

Fast drying speed, suitable for heat-sensitive materials, efficient production of complex powders with precise characteristics. |

| Coacervation Technique |

Not suitable for solvents.

Monodisperse.

Easy commercialization. |

| Ultrafiltration/Wash Filtration Technology |

The process of ultrafiltration concentrates liposomes and replaces the aqueous phase with a buffer or other clinically suitable solution, while also effectively eliminating any residual organic solvents present in the aqueous phase. Factors influencing this process include membrane material and pore size, transmembrane pressure (TMP), and tangential flow rate. |

Our Advantages in Liposome Formulation Process Development

- Extensive Expertise. Our experienced team specializes in developing and optimizing liposome formulations, providing tailored solutions for your specific needs.

- Advanced Technology. We utilize cutting-edge equipment like high-pressure homogenizers and nanosizers to achieve precise liposome size distribution and high encapsulation efficiency.

- Customizable Formulations. We can create liposome formulations customized to your requirements, including a wide range of lipids, additives, and drug payloads.

- Stringent Quality Control. We implement strict quality control measures throughout the development process to ensure consistent and reliable liposome formulations.

- Cost-effective Solutions. Our efficient processes and flexible project management approach provide cost-effective solutions that fit within your budget.

- Scalability. Our processes are designed for easy transition from benchtop to commercial-scale production without compromising efficiency or quality.

Published Data

Technology: Liposome drug product assessment technology

Journal: International Journal of Pharmaceutics

IF: 10.5

Published: 2021

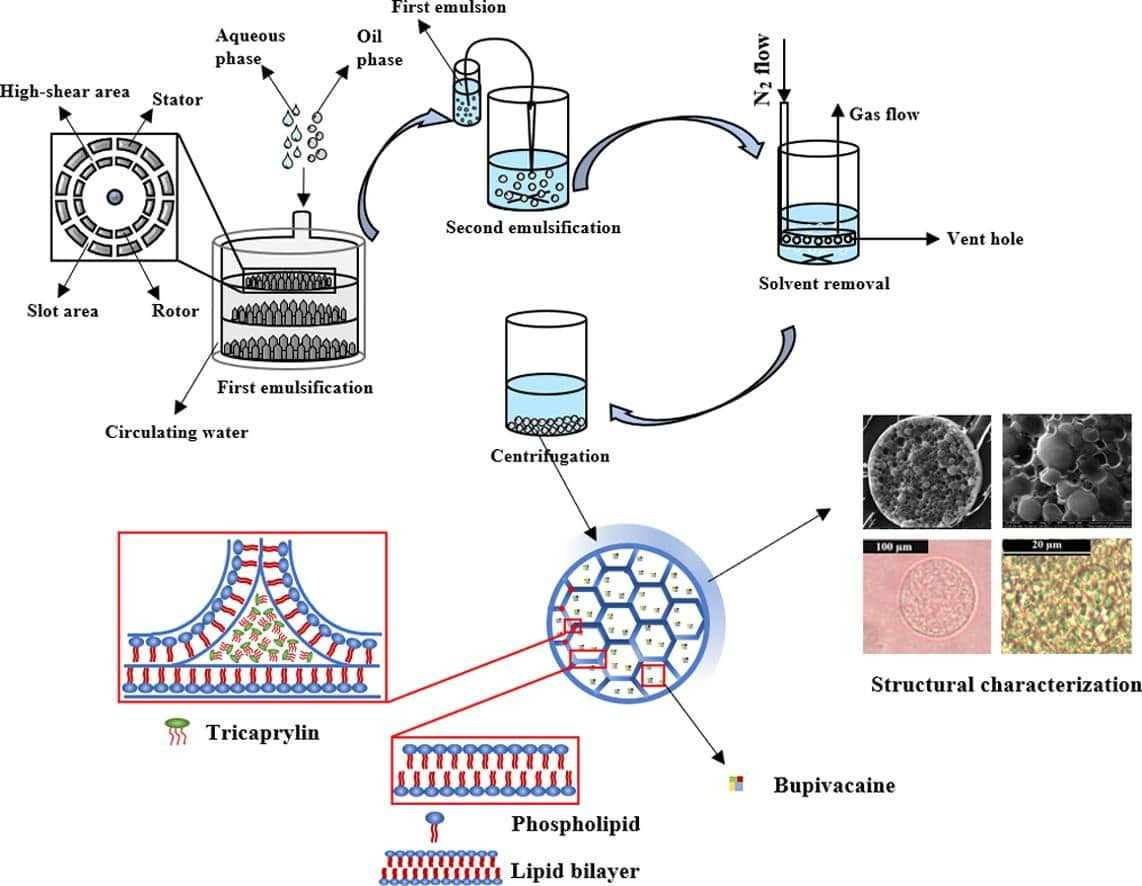

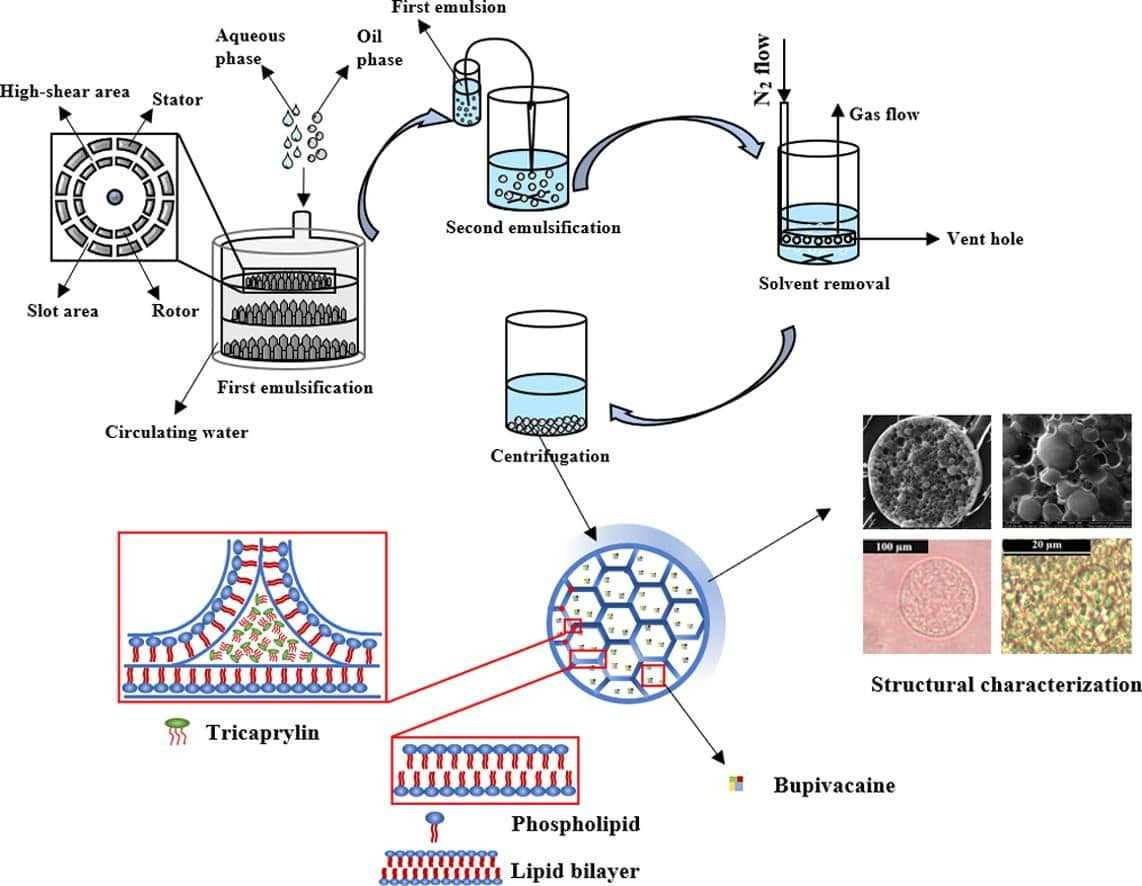

Results: In this study, the authors extended the Quality by Design (QbD) principle to liposome products containing hydrophilic active pharmaceutical ingredients (APIs). They argued for the feasibility and advantages of implementing the QbD concept based on a multi-vesicular liposome system. Bupivacaine, a local anesthetic, was selected as the model compound to evaluate three key attributes of the liposome drug product (particle size, morphology, and drug encapsulation efficiency) in order to assess the preparation process.

Fig.1 Process for assessing the liposome. (Bohong Lu, et al., 2020)

Fig.1 Process for assessing the liposome. (Bohong Lu, et al., 2020)

The services provided by CD Formulation are supported by cutting-edge technology and state-of-the-art equipment, ensuring a comprehensive and professional approach. If you have any particular needs, don't hesitate to contact us. Our team is on standby and ready to assist with any inquiries or consultations you may require.

References

- Bohong Lu, Qiuyan Ma, et al. Methods of Liposomes Preparation: Formation and Control Factors of Versatile Nanocarriers for Biomedical and Nanomedicine Application. Pharmaceutics. 2021 April, 598, 120335

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services