Active pharmaceutical ingredients (APIs) for veterinary use refer to various powders, crystals, and extracts prepared by chemical synthesis, plant extraction or biotechnology, which are used to make veterinary drugs, and cannot be directly fed. The production of APIs often has multiple process routes. The process routes will not only directly affect the possibility of industrial production of products, but also affect material costs, product quality and even the environment.

How Do We Develop Veterinary APIs Process?

CD Formulation boasts a diverse range of veterinary APIs manufacturing capabilities, enabling us to meet the demands of various veterinary pharmaceutical formulations with unparalleled expertise and quality assurance. We have complete process R&D technology platforms, which can provide small test, pilot test, and process development for large-scale production to help customers quickly realize product commercialization.

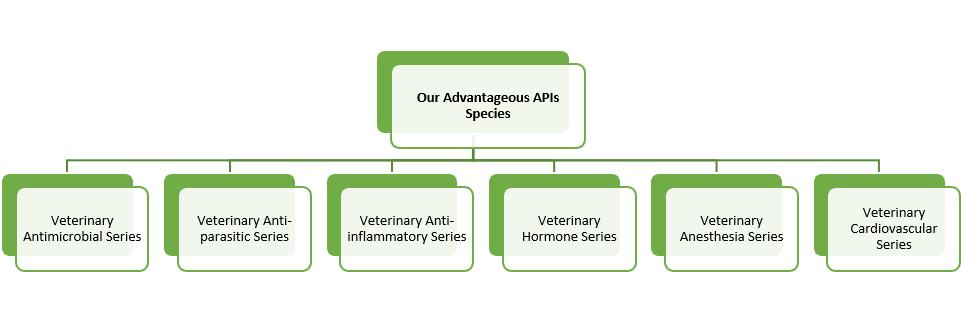

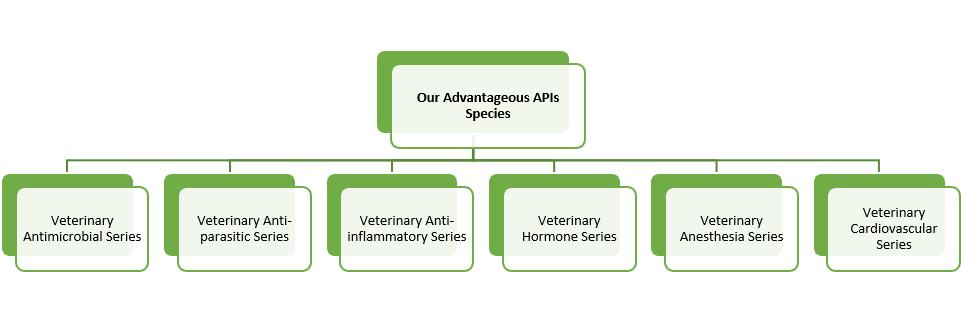

Veterinary APIs Species – CD Formulation

Veterinary APIs Species – CD Formulation

What Can We Do for Veterinary APIs Process Development?

- Route Design and Screening

CD Formulation first conducts research on the product to be developed, consults a large amount of information, analyzes the synthesis route and the source of the synthesis raw material, and analyzes the synthesis equipment and synthesis cost to understand whether there is any intellectual property problem in the synthesis route, whether the production cost is acceptable, whether meet green chemistry and more.

Our experienced team is able to carry out process optimization through parallel reactions, determine process parameters and perform process control. In our company, the process optimization of APIs is a dynamic process. With the continuous optimization of the process, we always pay attention to the changes in the specifications of starting materials, reagents or solvents, and reaction conditions, and evaluate the impact of these changes on product quality (such as crystal forms, impurities, etc.) Influence.

- Identification of Impurities

We can perform impurity identification, impurity profiling, synthesis and standard setting, and help you control product quality.

We can provide customers with samples that meet various quality standards, including for preclinical pharmacodynamics and toxicology studies, whether you need small quantities of APIs for initial development work or large quantities for late-stage trials. Our efficient work can help customers shorten the development cycle.

- Chemical Process Reaction Safety Evaluation

We can help with design space studies, production process risk assessments, and process safety testing and evaluation. We optimize process conditions and improve production safety by monitoring changes in parameters such as temperature, heat, and pressure during chemical reactions, physical mixing, distillation, and crystallization.

Based on our specialized analytical equipment, including gas chromatography, liquid chromatography and mass spectrometry, our experts will support your analytical needs at every stage with highly reliable stability, purity, analytical method development and quality control testing programs.

CD Formulation provides customers with professional and comprehensive technology transfer services, helping customers efficiently complete product technology transfer and project planning, while reasonably controlling costs and risks.

Highlights of Our Technology Platforms

- PROTAC technology

- Green chemical technology

- Peptide Technology

- Photocatalytic reaction

- Continuous response technology

- Isotope labeling and modification technology

- Bioelectronic isostere technology

- Fluorescent probe technology

- Fluorine chemical technology

- Macrocycle chemical technology

- Nucleotide chemistry technology

CD Formulation possesses extensive capabilities for the development of veterinary APIs, enabling us to meet diverse demands in veterinary pharmaceutical manufacturing with efficiency and expertise. If you are interested in our services, or have questions, please feel free to contact us!

Veterinary APIs Species – CD Formulation

Veterinary APIs Species – CD Formulation