Transdermal Delivery - CD Formulation

Call Us:

- Home

- Services

- Transdermal Formulation Development

- Gel Transdermal Formulation Development

- Cream Transdermal Formulation Development

- Ointment Transdermal Formulation Development

- Spray Transdermal Formulation Development

- Transdermal Patch Development

- Single-Layer Drug-In-Adhesive Transdermal Patch Development

- Multi-Layer Drug-In-Adhesive Transdermal Patch Development

- Matrix Transdermal Patch Development

- Reservoir Transdermal Patch Development

- Vapor Transdermal Patch Development

- Active Gel Transdermal Patch Development

- Controlled Release Transdermal Patch Development

- Transdermal Microneedle Patch Development

- Nano Transdermal Patch Development

- Nanofiber/Microfiber Transdermal Patch Development

- Microemulsion/Nanoemulsion Transdermal Patch Development

- Metal Nano Transdermal Patch Development

- Solid Lipid Nano Transdermal Patch Development

- Polymer Nano Transdermal Patch Development

- Vesicle Nano Transdermal Patch Development

- Nano Gel Transdermal Patch Development

- Liposome Transdermal Patch Development

- Nanocrystal Transdermal Patch Development

- Ethosomes Transdermal Patch Development

- Peptide Transdermal Formulation Development

- Protein Transdermal Formulation Development

- Nucleic Acid Transdermal Formulation Development

- Transdermal Formulation Analysis and Testing Services

- Conventional Characterization for Transdermal Formulation

- Transdermal Formulation Appearance Analysis

- Transdermal Formulation Rheological Properties Analysis

- Transdermal Formulation Weight Testing

- Transdermal Formulation Thickness Testing

- Transdermal Formulation Folding Endurance Testing

- Transdermal Formulation Moisture Absorption Rate Testing

- Transdermal Formulation Moisture Content Percentage Testing

- Transdermal Formulation Surface pH Testing

- Transdermal Formulation Swelling Index Testing

- Transdermal Formulation Tensile Strength Testing

- Transdermal Formulation Drug Content and Excipient Content Assays

- Transdermal Formulation Drug Content Uniformity Testing

- Transdermal Formulation Crystal Structure Analysis

- Transdermal Formulation Peel Adhesion Testing

- Transdermal Formulation Shear Testing

- Transdermal Formulation Release Liner Removal Testing

- Transdermal Formulation Tack Testing

- Transdermal Formulation Cold Flow Evaluation

- Transdermal Formulation Residual Drug Analysis

- In Vitro Penetration Testing of Transdermal Formulation

- In Vitro Release Testing of Transdermal Formulation

- Nanoproperty Characterization for Transdermal Formulation

- Quality Control and Release Testing for Transdermal Formulation

- Transdermal Formulation API and Excipient Characterization

- Transdermal Formulation Analytical Method Development and Validation

- Transdermal Formulation Analytical Method Transfer

- Transdermal Formulation Batch Release Testing

- Transdermal Formulation Residual Solvents Testing

- Transdermal Formulation Extractables and Leachables Testing

- Transdermal Formulation Elemental Impurities Testing

- Transdermal Formulation Impurity Analysis

- Transdermal Formulation Stability Testing

- Transdermal Formulation Temperature Cycling Testing

- Transdermal Formulation Forced Degradation Testing

- Transdermal Formulation Packaging Integrity Testing

- Transdermal Formulation Bioequivalence Evaluation

- Conventional Characterization for Transdermal Formulation

- Biological Evaluation for Transdermal Formulation

- GMP Manufacturing Services of Transdermal Formulation

- Transdermal Formulation Development

- Technologies

- Applications

- Order Online

- Company

- Inquiry

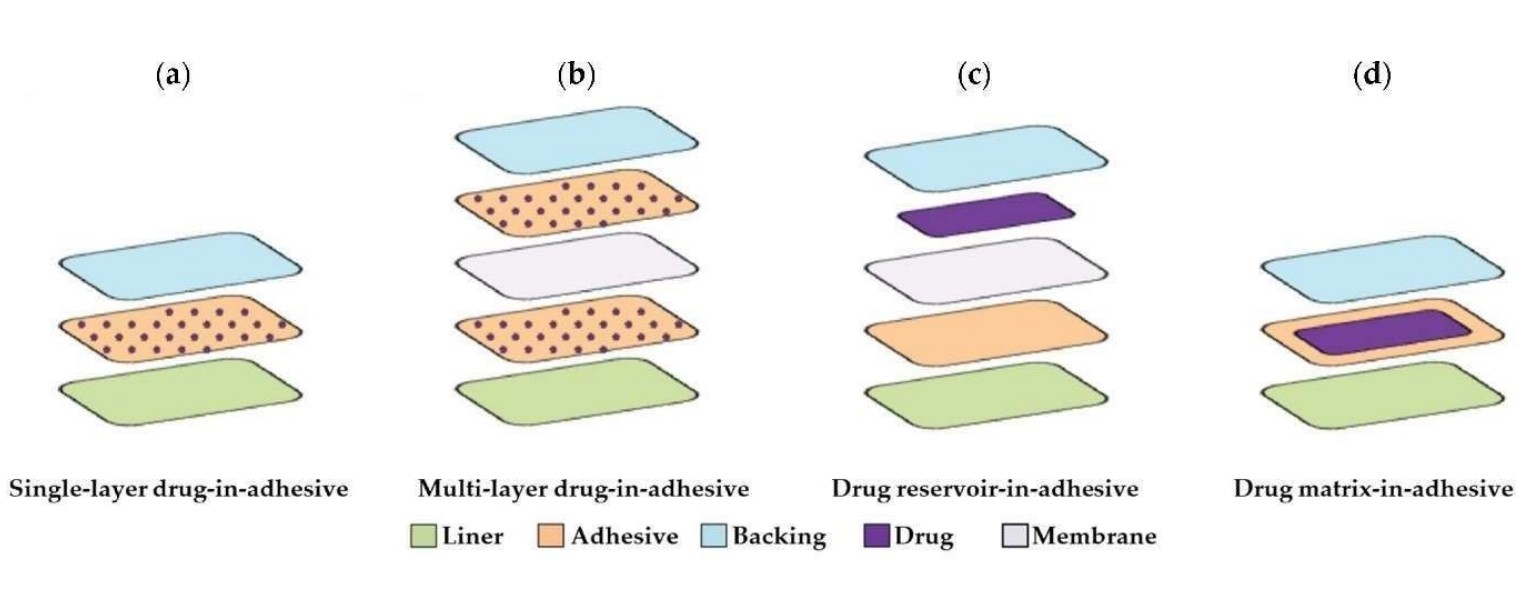

Fig.1 Illustrates various types of transdermal delivery patches: (a) Single-layer drug-in-adhesive patch;(b) Multi-layer drug-in adhesive patch; (c) Drug reservoir-in-adhesive patch; (d) Drug matrix-in-adhesive patch. (Naziya Shaikh, et al. 2024)

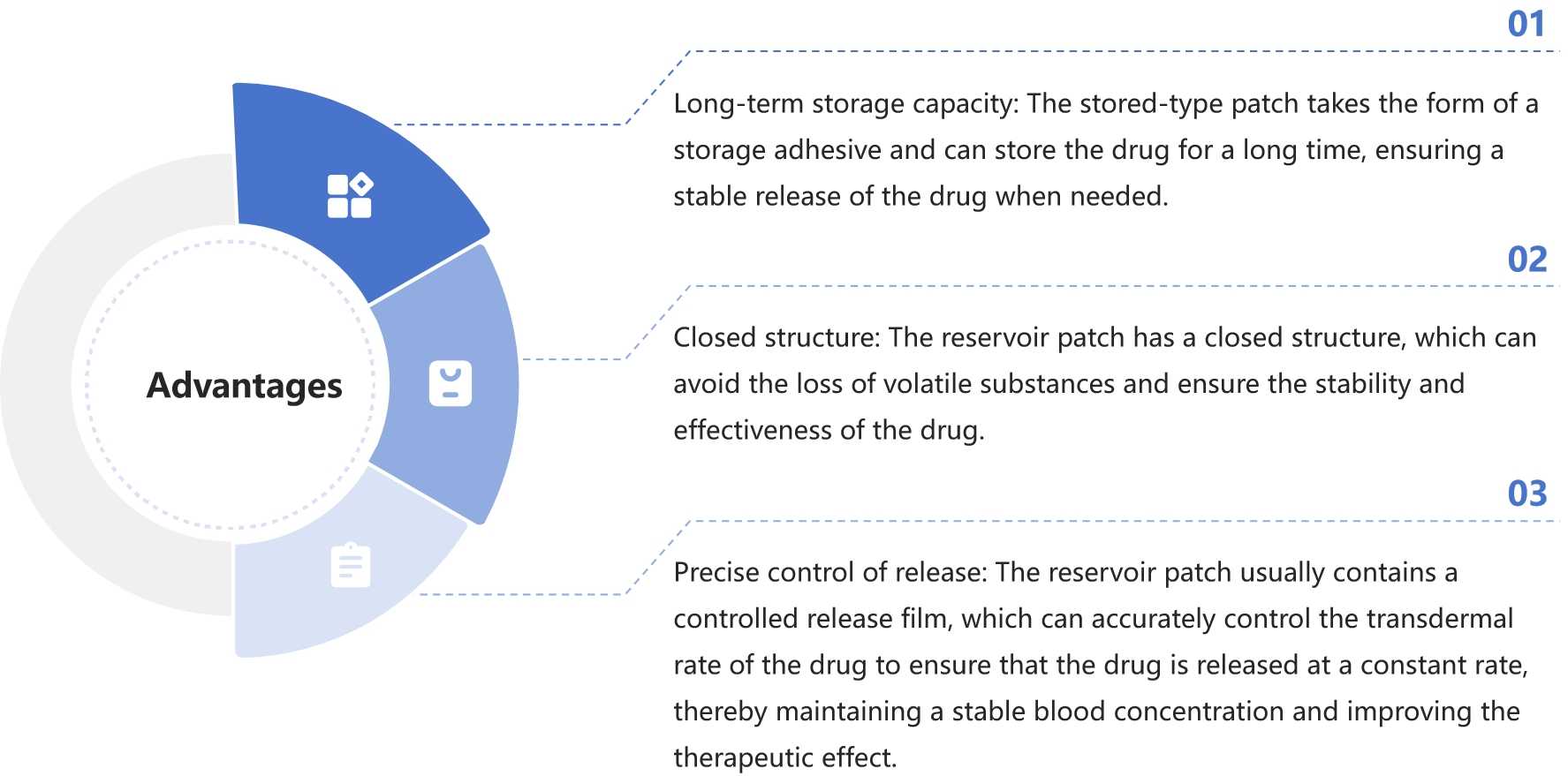

Fig.1 Illustrates various types of transdermal delivery patches: (a) Single-layer drug-in-adhesive patch;(b) Multi-layer drug-in adhesive patch; (c) Drug reservoir-in-adhesive patch; (d) Drug matrix-in-adhesive patch. (Naziya Shaikh, et al. 2024) Fig.2 Advantages of Reservoir Transdermal Patches (CD Formulation)

Fig.2 Advantages of Reservoir Transdermal Patches (CD Formulation)