Therapeutic Proteins & Peptides - CD Formulation

Call Us:

- Home

- Services

- Therapeutic Peptide Synthesis and Production

- Therapeutic Peptide Chemical Synthesis

- Therapeutic Peptide Biosynthesis

- Custom Specialty Peptides Synthesis

- Multiple Antigenic Peptide (MAP) Synthesis

- Cyclic Peptide Synthesis

- Stapled Peptide Synthesis

- Long Peptide Synthesis

- Cell Penetrating Peptide (CPP) Synthesis

- Linear Peptide Synthesis

- Peptoid Synthesis

- Disulfide-Rich Peptide (DSR) Synthesis

- Peptide Antigens Synthesis

- D-Amino Acid-Containing Peptide Synthesis

- Bicyclic Peptide Synthesis

- Custom Modified Peptide Synthesis

- C-Terminal Modified Peptide Synthesis

- N-Terminal Modified Peptide Synthesis

- Unusual & Non-natural Amino Acids Modified Peptide Synthesis

- Phosphorylated Peptide Synthesis

- Prenylated Peptide Synthesis

- Sulphated Peptide Synthesis

- PEGylated Peptide Synthesis

- Biotinylated Peptide Synthesis

- Glycosylated Peptide Synthesis

- Acetylated Peptide Synthesis

- Amidated Peptide Synthesis

- Methylated Peptide Synthesis

- Peptide Dimer Synthesis

- Fatty Acid Modified Peptide Synthesis

- Custom Labeled & Conjugated Peptide Synthesis

- Enzyme Labeled Peptide Synthesis

- Isotope Labeled Peptide Synthesis

- Imaging Agent Labeled Peptide Synthesis

- Quenched Fluorescent Peptide (FRET Peptide) Synthesis

- Fluorescence Labeled Peptide Synthesis

- Carrier Protein-Conjugated Peptide Synthesis

- DNA-Conjugated Peptide Synthesis

- RNA-Conjugated Peptide Synthesis

- siRNA-Conjugated Peptide Synthesis

- Nanoparticle-Conjugated Peptide Synthesis

- Gold Nanoparticle-Conjugated Peptide Synthesis

- Therapeutic Peptide Library

- Therapeutic Peptide Array

- Large Scale Therapeutic Peptide Synthesis

- Neoantigen Peptide Service

- Therapeutic Protein Production & Engineering

- Therapeutic Protein Production

- Yeast Expression System-Based Therapeutic Protein Production

- Baculovirus-Insect Cell Expression System-Based Therapeutic Protein Production

- Escherichia Coli Expression System-Based Therapeutic Protein Production

- Mammalian Cell Expression System-Based Therapeutic Protein Production

- Glyco-Engineering-Based Therapeutic Protein Production

- Eukaryotic Algae Engineering-Based Therapeutic Protein Production

- Therapeutic Protein Engineering

- Therapeutic Protein Production

- Therapeutic Proteins & Peptides Process Development

- Cell Line Development for Therapeutic Proteins & Peptides

- Therapeutic Proteins & Peptides Upstream Cell Culture Process Development

- Therapeutic Proteins & Peptides Upstream Fermentation Process Development

- Therapeutic Peptides Upstream Synthetic Process Development

- Therapeutic Proteins Downstream Purification Process Development

- Therapeutic Peptides Downstream Purification & Isolation Process Development

- Therapeutic Proteins & Peptides Formulation Process Development

- Therapeutic Proteins & Peptides Process Characterization and Process Validation

- Therapeutic Proteins & Peptides Production Process Scale-up

- Therapeutic Proteins & Peptides Technology Transfer

- Proteins & Peptides Formulation Research and Development

- Proteins & Peptides Pre-formulation Studies

- Proteins & Peptides Formulation Development

- Proteins & Peptides Liquid Formulation Development

- Proteins & Peptides Sterile Formulation Development

- Proteins & Peptides Buffer-free Lyophilized Formulation Development

- Proteins & Peptides High-concentration Formulation Development

- Protein & Peptide Lyophilization Formulation Development

- Proteins & Peptides Spray Drying Formulation Development

- Proteins & Peptides Drug Delivery System Development

- Proteins & Peptides Oral Delivery System Development

- Proteins & Peptides Transdermal Delivery System Development

- Proteins & Peptides Injectable Delivery System Development

- Proteins & Peptides Inhaled Delivery System Development

- Proteins & Peptides Intranasal Delivery System Development

- Proteins & Peptides Innovative Delivery System Delivery Development

- Proteins & Peptides Liposomal Delivery System Development

- Proteins & Peptides Microneedle Delivery System Development

- Proteins & Peptides Microspheres Delivery System Development

- Proteins & Peptides Nanoparticles Delivery System Development

- Proteins & Peptides Microemulsion Delivery System Development

- Proteins & Peptides Hydrogels Delivery System Development

- Packaging Material Screening and Testing Services for Protein & Peptide Formulation

- Proteins & Peptides Characterization and Analytical Testing Services

- Therapeutic Proteins & Peptides Characterization

- Proteins & Peptides Primary Structure Characterization

- Higher-Order Structures (HOS) Proteins & Peptides Characterization

- Peptide Mapping Analysis

- Proteins & Peptides Particle and Aggregation Characterization

- Proteins & Peptides Viscosity Analysis

- Proteins & Peptides Quantitative Analysis

- Proteins & Peptides Sequencing Analysis

- Amino Acid Analysis

- Post-translational Modifications (PTMs) Analysis

- Proteins & Peptides Stability and Thermal Denaturation Analysis

- Proteins & Peptides Crystal Structure Elucidation

- Proteins & Peptides Druggability Assessment

- Proteins & Peptides Formulation Analysis

- Proteins & Peptides Quality Control and Release Testing

- Proteins & Peptides Analytical Method Development

- Proteins & Peptides Analytical Method Validation and Transfer

- Proteins & Peptides Product-related Impurity Analysis

- Proteins & Peptides Process-related Impurity Analysis

- Proteins & Peptides Elemental-related Impurity Analysis

- Proteins & Peptides Residual Solvent and Volatile Impurity Analysis

- Proteins & Peptides Extractables and Leachables Analysis

- Proteins & Peptides Residual Host Cell DNA Testing

- Proteins & Peptides Residual Host Cell Protein (HCP) Analysis

- Virus Clearance Testing

- Cell Line Characterization

- Proteins & Peptides Biosimilarity Studies

- Proteins & Peptides Comparability Studies

- Proteins & Peptides Stability Testing

- Proteins & Peptides Forced Degradation Studies

- Proteins & Peptides Batch-release Testing

- Proteins & Peptides Biological Evaluation

- Therapeutic Proteins & Peptides Characterization

- Proteins & Peptides cGMP Manufacturing

- Therapeutic Peptide Synthesis and Production

- Technologies

- Prtoein & Peptide Characterization Technologies

- Dynamic Light Scattering (DLS) Technology

- Differential Scanning Fluorescence (DSF) Technology

- Analytical Ultracentrifugation (AUC) Technology

- Differential Scanning Calorimetry (DSC) Technology

- Asymmetrical Flow Field-Flow Fractionation (AF4) Technology

- Hollow Fiber Flow-Field-Flow Fractionation (HF5) Technology

- Nanoparticle Tracking Analysis (NTA) Technology

- Micro-Flow Imaging (MFI) Technology

- Multi-angle Light Scattering (MALS) Technology

- Multi-angle Dynamic Light Scattering (MADLS) Technology

- X-ray Diffraction (XRD) Technology

- UV-Vis Spectrophotometry Technology

- Circular Dichroism (CD) Spectroscopy Technology

- Fourier Transform Infrared (FT-IR) Spectroscopy Technology

- Cryo-electron Microscopy (cryo-EM) Technology

- Small-angle X-ray Scattering (SAXS) Technology

- Mass Spectrometry (MS)-Based Sequencing Technology

- Hydrogen-Deuterium Exchange Mass Spectrometry (HDX-MS) Technology

- Isoelectric Focusing (IEF) Technology

- Capillary Isoelectric Focusing (cIEF) Technology

- Capillary Zone Electrophoresis-Mass Spectrometry (CZE-MS) Technology

- SDS-PAGE Technology

- Capillary Gel Electrophoresis (CGE) Technology

- Surface Plasmon Resonance (SPR) Technology

- Viral Titers Determination Using TCID50

- Liquid Chromatography (LC) Technologies

- Ion Exchange Chromatography (IEX) Technology

- Hydrophobic Interaction Chromatography (HIC) Technology

- Size Exclusion Chromatography (SEC) Technology

- Affinity Chromatography (AC) Technology

- Reversed-phase Chromatography (RP-HPLC / RP-UPLC) Technology

- Mixed Mode Chromatography (MMC) Technology

- Fast Protein Liquid Chromatography (FPLC) Technology

- Tangential Flow Filtration (TFF) Technology

- Membrane Filtration Technology

- Protein Expression Technologies

- Peptide Synthesis Technologies

- Prtoein & Peptide Characterization Technologies

- Online Order

- Company

- Inquiry

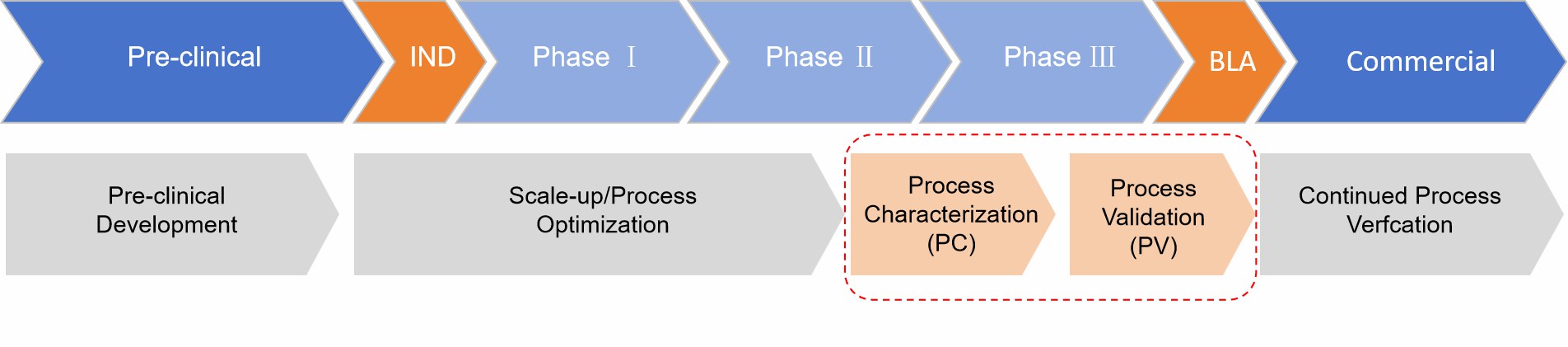

Fig. 1 Process characterization and process validation in the drug development process. (CD Formulation)

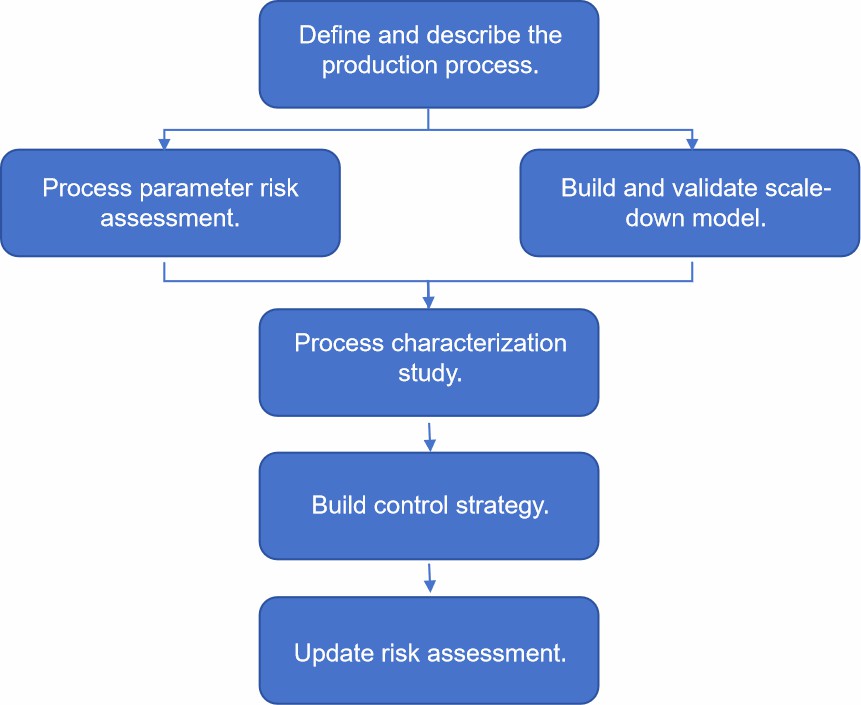

Fig. 1 Process characterization and process validation in the drug development process. (CD Formulation) Fig. 2 Process characterization (PC) flow. (CD Formulation)

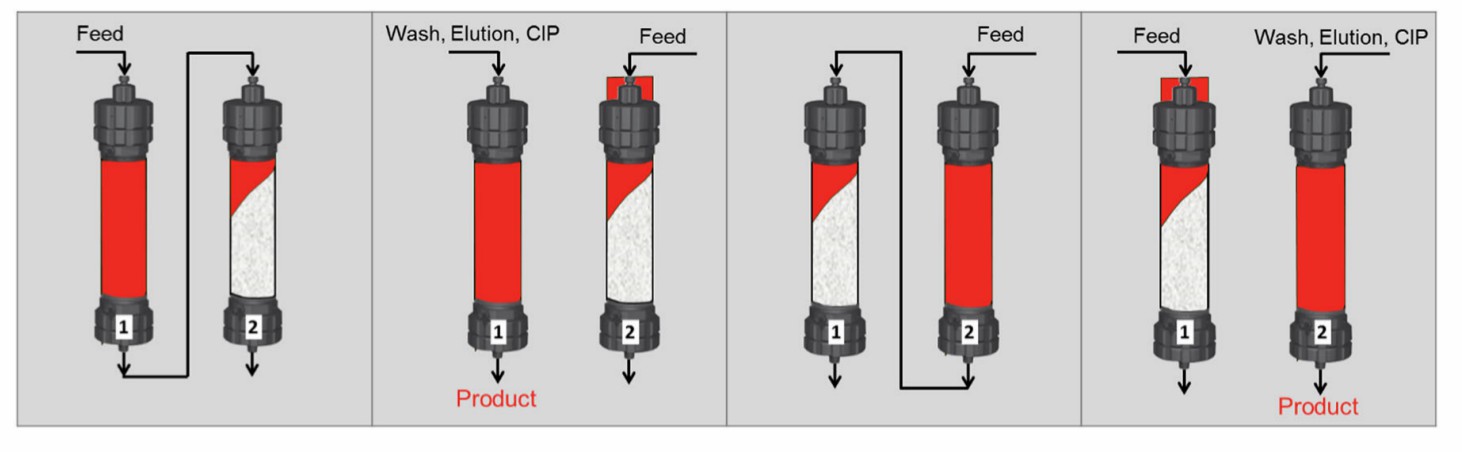

Fig. 2 Process characterization (PC) flow. (CD Formulation) Fig. 3 Schematic of one cycle of the twin-column CaptureSMB process. (Angelo J, et al., 2019)

Fig. 3 Schematic of one cycle of the twin-column CaptureSMB process. (Angelo J, et al., 2019)