Thermogravimetric (TGA) Analysis for Oral Thin Film

Inquiry

Since a thermal process is utilized in current oral thin film manufacturing to achieve molecular-level mixing and film forming, thermal degradation of the drug or excipients used in the formulation may occur due to the high processing temperatures of casting, extrusion, and printing. Therefore, thermogravimetric (TGA) analysis is often used to evaluate the thermal behavior of the formulation and select a suitable processing temperature range before oral thin film manufacturing. CD Formulation provides professional TGA analysis to gain a deeper understanding of the thermal behavior of oral thin film samples, thereby assisting in the development and commercialization of oral dissolved film products.

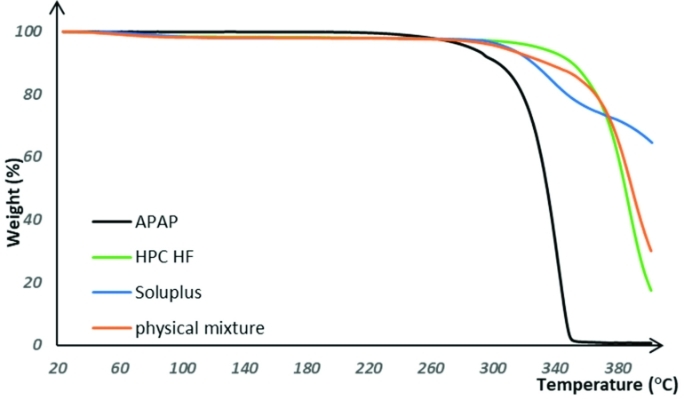

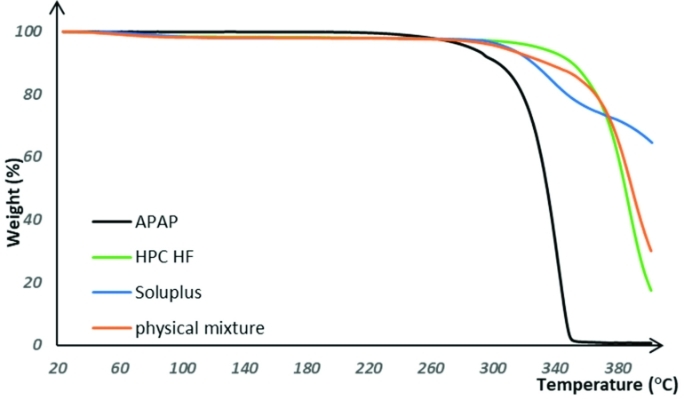

Fig.1 The thermal degradation curves for raw materials and physical mixtures.

Fig.1 The thermal degradation curves for raw materials and physical mixtures.

(Jiaxiang Zhang, et al., 2021)

What is Oral Thin Film TGA Analysis?

The TGA analysis is a technique used to measure the changes in an oral thin film's weight as a function of temperature or time in a controlled atmosphere. During TGA, the oral thin film samples are heated in a controlled environment, and any weight loss or gain is monitored. This can provide valuable information about the composition, thermal stability, decomposition, and moisture content of the material being analyzed.

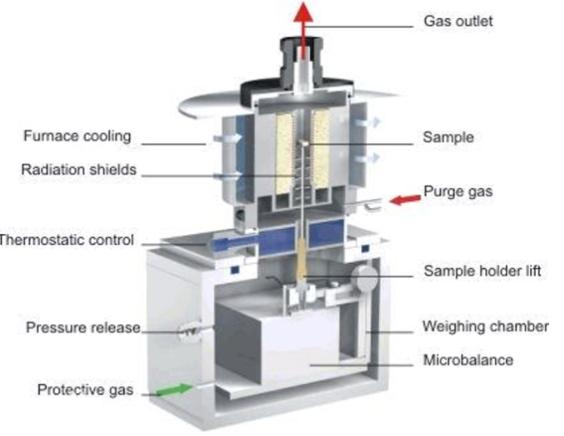

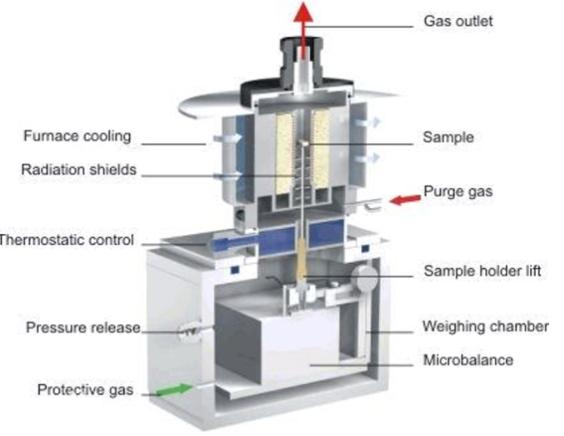

Fig.2 Thermogravimetric analyzer.

Fig.2 Thermogravimetric analyzer.

The Importance of Oral Thin Film TGA Analysis

- The TGA analysis can aid in selecting a suitable processing temperature range.

- The TGA analysis can help identify any degradation products in the thin film that undergo thermal decomposition, which can ensure the safety and efficacy of the drug delivery system.

- The TGA analysis helps determine the temperature at which the film starts to decompose, providing insight into its thermal stability.

Our Oral Thin Film TGA Analysis Services

TGA analysis is important in the solid-state characterization of oral thin films, when the thin film sample sublimates, vaporizes, decomposes gas, or loses crystal water during heating, the quality of the sample will change. In this case, the TGA curve is not a straight line but a decline. By analyzing the TGA curve, we can know to what degree the film under test changes, and based on the weight loss, we can calculate how much substance is lost. TGA analysis helps study the physical phenomena of crystal properties such as melting, evaporation, sublimation, and adsorption. It also helps to study the chemical phenomena of oral thin film samples such as dehydration, dissociation, oxidation, and reduction.

Workflow of Our Oral Thin Film TGA Analysis

CD Formulation has professional TGA analysis technicians who can help customers to provide accurate TGA analysis results, our service process is as follows:

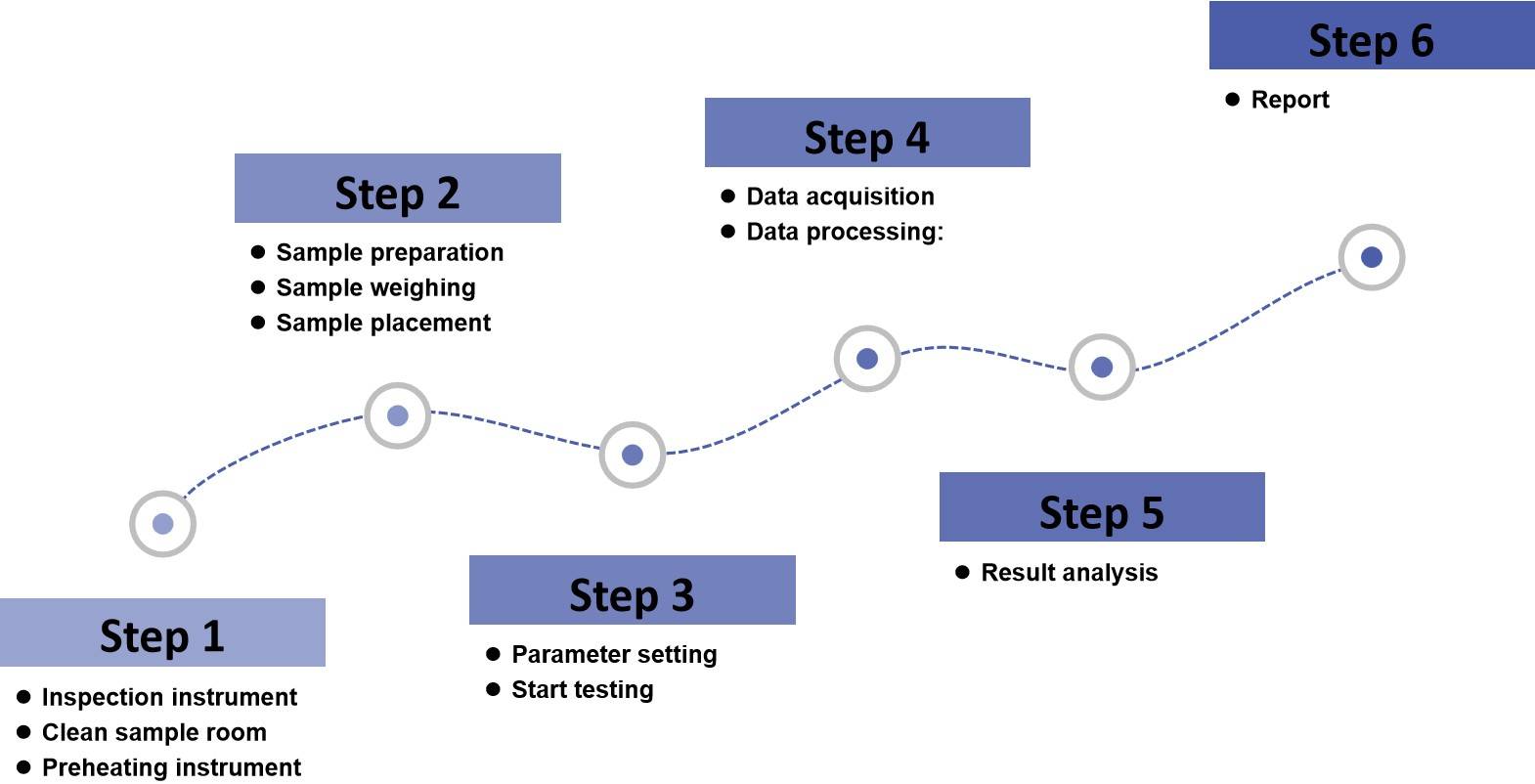

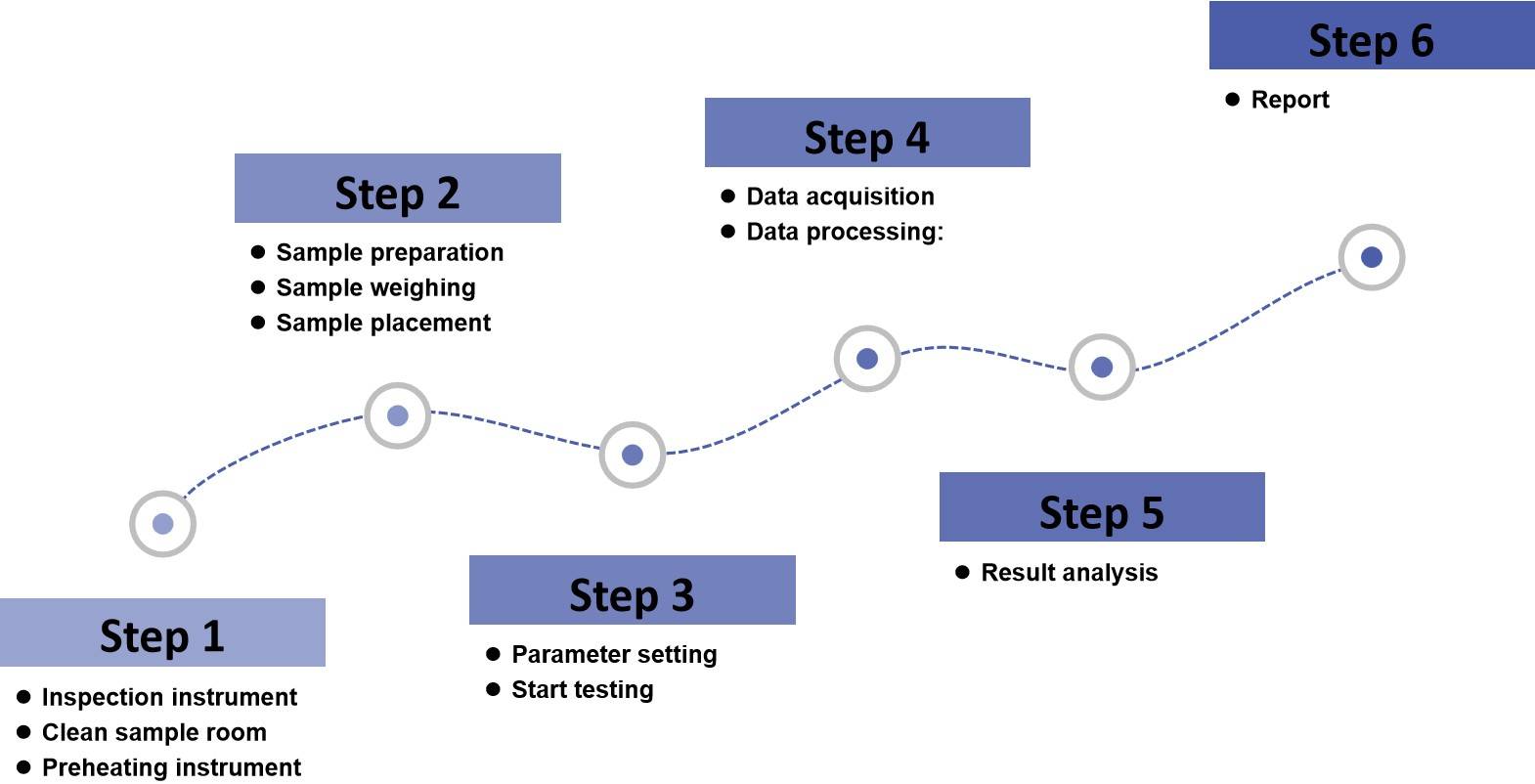

Fig.3 Workflow of Oral Thin Film TGA Analysis Services. (CD Formulation)

Fig.3 Workflow of Oral Thin Film TGA Analysis Services. (CD Formulation)

Preparation Before Experiment: We will communicate with customers about their testing needs and make detailed experimental plans. Before the start of the experiment, our specialized technicians will thoroughly clean the sample room, test the instrument, and preheat the experimental instrument to ensure the accuracy of the experimental results.

Sample Preparation: Prepare the sample according to the instrument requirements and experimental scheme.

Analysis: Set instrument parameters and put in samples for testing.

Data Analysis and Report: After completing sample analysis, analyze and process the data, and write a report.

Our Oral Thin Film TGA Analysis Capabilities

| TGA Analysis |

Detailed Information |

| Thermogravimetric analyzer |

We have the latest TGA analysis equipment, we can help our clients determine the temperature at which the oral thin film begins to degrade, estimate the number of volatile components present, and assess its overall thermal stability. |

Advantages of Our Oral Thin Film TGA Analysis

- Rapid Analysis: We provide quick and efficient oral thin film TGA analysis services.

- Accurate Results: We use state-of-the-art equipment and techniques to ensure accurate and reliable TGA analysis results.

- Comprehensive Insight: We offer in-depth TGA analysis, providing a thorough understanding of thermal properties, degradation behavior, and stability of oral thin film formulations.

Published Data

Technology: Thermogravimetric analysis (TGA)

Journal: Bioengineering

IF: 5.0

Published: 2018

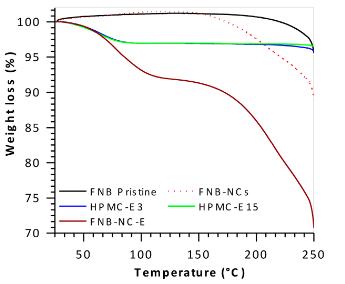

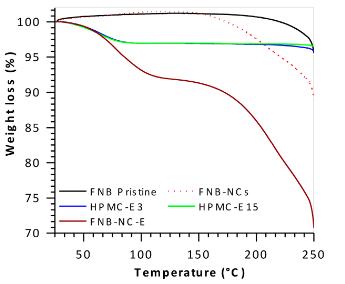

Results: The purpose of this study was to make a fenofibrate (FNB) nanocrystal (NC) by wet media milling, characterizations, and formulation into oral strip films (OSFs). Thermogravimetric analysis (TGA) was carried out within 30-250 ℃ at the heating rate of 10 ℃/min under nitrogen flow (20 mL/min) using a TGA/DSC STARe system. The results show that the TGA curve of pristine FNB shows a single-step weight loss at ~248 ℃. This strong endothermic peak also observed in TGA patterns, was an indication of FNB degradation. The TGA curve of FNB-NCs demonstrated endothermic weight loss peaks in four steps at 65 ℃, 120 ℃, 200 ℃, and 248 ℃. The first weight loss peak observed for HPMC-E3 corresponds to the evaporation of water. Curves of OSFs containing FNB-NCs clearly showed weight loss in three different steps at 80 ℃, 215 ℃, and 248 ℃. These steps were directly correlated with those of the HPMC placebo OSF samples (85 ℃, 200 ℃, and 235 ℃) and FNB-NCs (248 ℃).

Fig.4 Thermogravimetric analysis patterns. (Bhavesh D. Kevadiya, et al., 2021)

Fig.4 Thermogravimetric analysis patterns. (Bhavesh D. Kevadiya, et al., 2021)

We have a professional TGA analysis team that specializes in TGA analysis of oral thin film, ensuring that our clients receive insights and recommendations tailored to the unique properties of oral thin film products. If you require our oral thin film TGA analysis, please contact us by phone or email, and our colleagues will get back to you within three working days.

References

-

Jiaxiang Zhang, Anqi Lu, et al. Development and Evaluation of Amorphous Oral Thin Films Using Solvent-Free Processes: Comparison between 3D Printing and Hot-Melt Extrusion Technologies. Pharmaceutics. 2021,13(10).

- Bhavesh D. Kevadiya, Manish Barvaliya, et al. Fenofibrate Nanocrystals Embedded in Oral Strip-Films for Bioavailability Enhancement. Bioengineering. 2018, 5(1).

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 The thermal degradation curves for raw materials and physical mixtures.

Fig.1 The thermal degradation curves for raw materials and physical mixtures. Fig.2 Thermogravimetric analyzer.

Fig.2 Thermogravimetric analyzer. Fig.3 Workflow of Oral Thin Film TGA Analysis Services. (CD Formulation)

Fig.3 Workflow of Oral Thin Film TGA Analysis Services. (CD Formulation) Fig.4 Thermogravimetric analysis patterns. (Bhavesh D. Kevadiya, et al., 2021)

Fig.4 Thermogravimetric analysis patterns. (Bhavesh D. Kevadiya, et al., 2021)