Plasticizer Screening of Oral Thin Film

Inquiry

The plasticizer is an important component of oral thin films, the commonly used plasticizers are ethanol, propylene glycol, low molecular weight polyethylene glycol, and phthalic dimethyl ester, etc. Generally, the amount of plasticizer ≤ 20% can effectively prevent cracking and wrinkling after the film dries. CD Formulation screen is the most suitable plasticizer based on the type of oral thin film and compatibility with film-forming agents, etc.

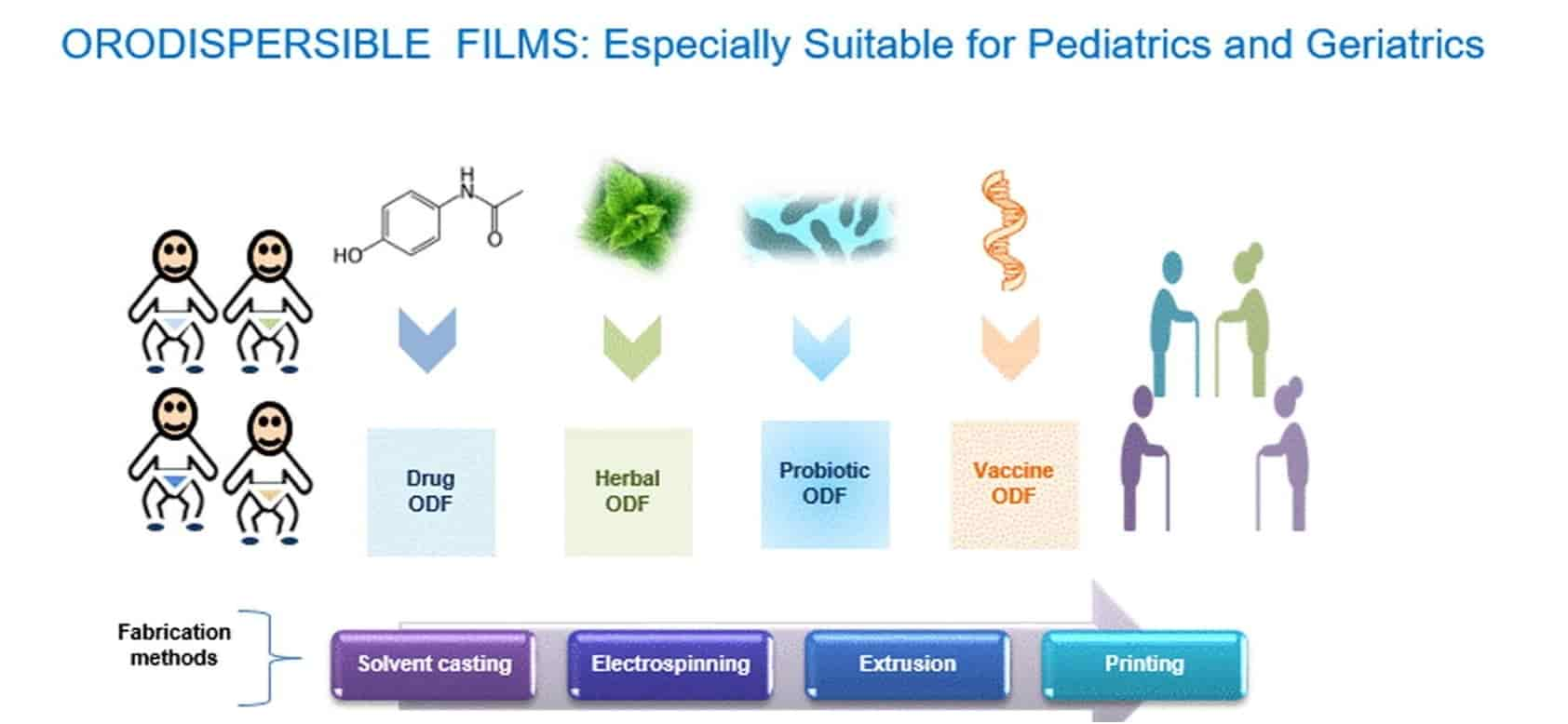

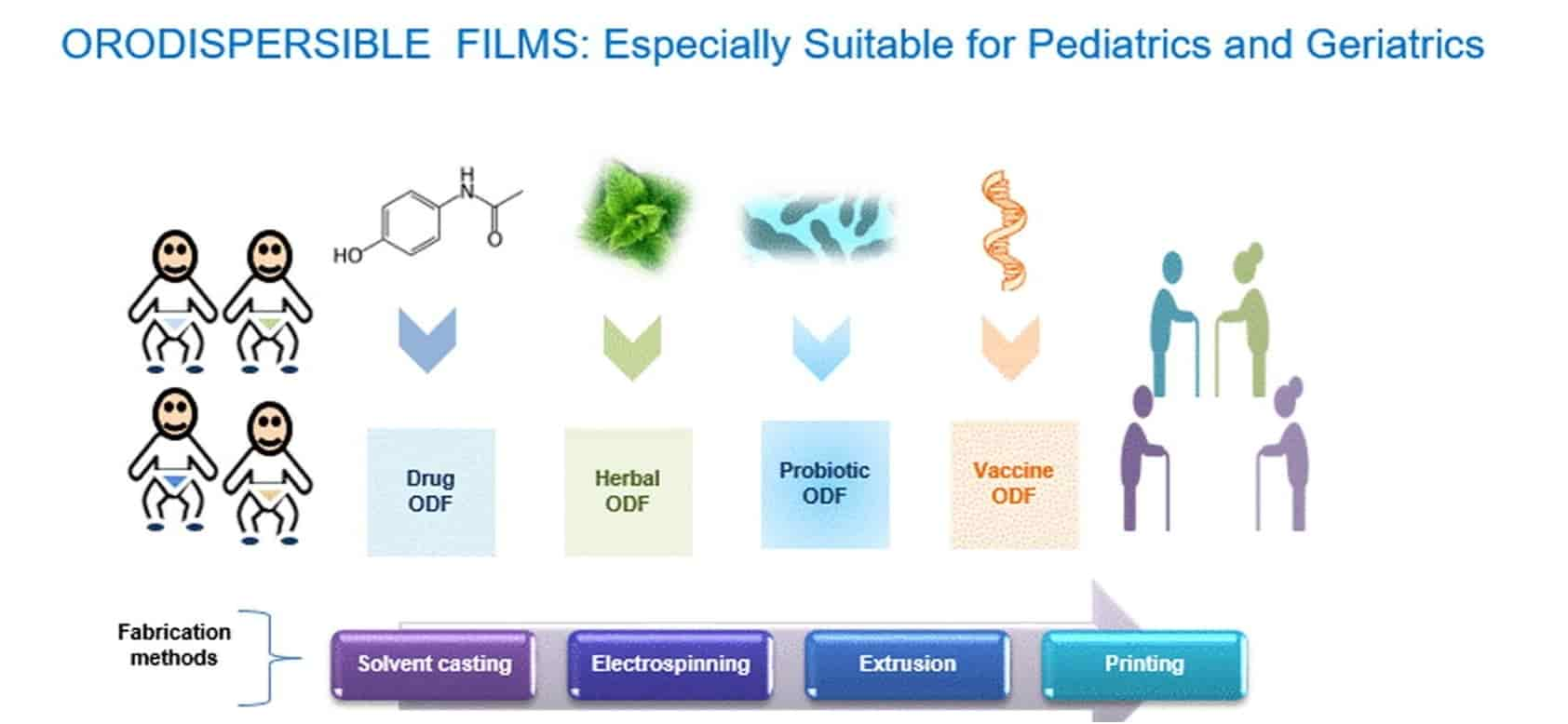

Fig.1 Orodispersible films: Conception to quality by design. (Maram Suresh Gupta, et al., 2021)

Fig.1 Orodispersible films: Conception to quality by design. (Maram Suresh Gupta, et al., 2021)

The Importance of Plasticizer Screening for Oral Thin Film Development

- Help to improve the mechanical properties of the oral thin films, such as tensile strength and elongation, etc.

- Reduce the brittleness of the film.

- Improve the fluidity.

- Increase the strength of the polymer.

Our Plasticizer Screening Services

Based on the quality by design (QbD) principle in the development of oral thin film, we investigate the appearance, tensile strength, drug release rate, and compatibility with film-forming agent, and screen the most suitable plasticizer to ensure the development of high-quality oral thin film.

Appearance

Improper selection of plasticizers may result in cracking and spalling of the film. In the design of plasticizer screening formulation, the appearance is an evaluation index that cannot be ignored. The appearance of the oral thin film should be complete, without cracks and without shedding, etc.

Tensile Strength

The oral thin film is pulled by external forces during the process of taking and applying them. If the toughness and strength are not enough, they are often prone to tearing and breakage. The screen of plasticizers should consider the tensile strength.

Drug Release Rate

The type and dosage of plasticizers will also affect the morphology and drug release rate of oral thin film, we will choose according to specific needs.

Compatibility with Film-forming Agent

The effect of different film-forming materials on plasticizers is also selective. For example, cellulose hydrophilic derivatives as film-forming materials are very sensitive to plasticizers containing hydroxyl groups, such as polyethylene glycol, while polyvinyl alcohol as a film-forming material is more suitable for using glycerol as a plasticizer.

Our Platforms for Oral Thin Film Plasticizer Screening

| Technologies & Platform |

Description |

| Tensile Strength Testing Technology Platform |

Tensile strength is the maximum stress applied to a point of film at which the strip specimen breaks. A film should have good tensile strength. Load failure refers to the weight at which the film breaks. Tensile strength is calculated by the applied load at rupture divided by the cross-sectional area of the strip. |

| In-Vitro Disintegration Testing Technology Platform |

The drug release rate is usually expressed as in vitro dissolution. The disintegration time of a film is determined using disintegration machinery stated in authoritative pharmacopoeias. The disintegration time is usually a function of the film composition since it changes with the formulation, and it typically spans from 5 to 30 seconds. This test is commonly performed using the USP disintegration device. |

| Compatibility Study Technology Platform |

We are familiar with the study guidelines of the compatibility of oral thin film and explore the compatibility between film-forming agents and candidate plasticizers to provide a basis for the selection of plasticizers. |

Advantages of Our Plasticizer Screening Services

- Comprehensive Evaluation: We will evaluate plasticizers from the aspects of safety, effectiveness, stability, economy, and compliance to help customers select the most suitable plasticizers.

- Systematic Study: In the plasticizer screening process of oral thin films, we will focus more on systematically studying the characteristics of oral thin films, careful thinking, and observation.

- Strict: We always combine of plasticizers with the formulation composition and production process of the finished product and conduct comprehensive quality control of plasticizers.

- Professional: Our expert team is familiar with the advantages and disadvantages of various plasticizers and the development of oral thin films and can adjust the plasticizers at any time according to the characteristics of the developed oral thin films.

Published Data

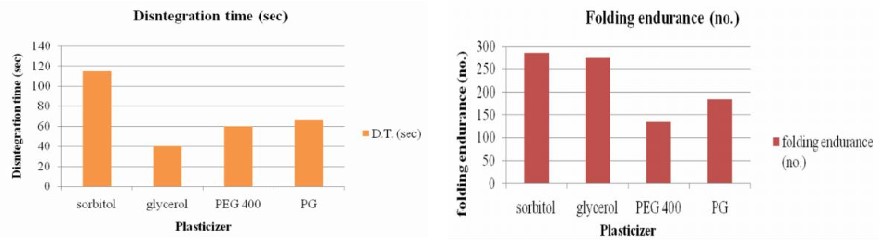

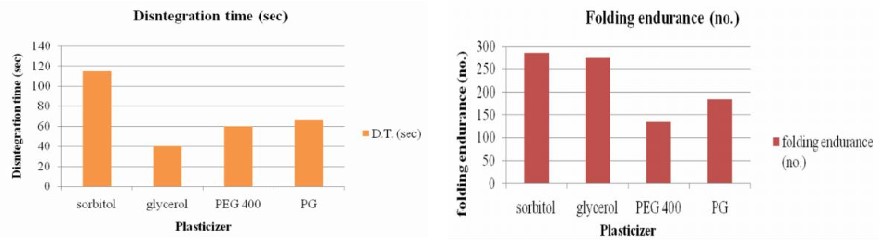

Technology: Effect of plasticizers on fast dissolving oral films

Journal: International Journal of PharmTech Research

IF: 3.3

Published: 2013

Results: The different batches of oral films with different plasticizers were prepared and evaluated for various parameters. The results show that plasticizers have influence on disintegration time and folding endurance. PG was found to be better plasticizer than PEG 400 for the preparation of films. Polyethylene glycol 400 (PEG 400) and propylene glycol (PG) were selected as the plasticizers to be used separately. In addition, concentration of PEG 400 and PG less than 10% was not enough to plasticize the films because the formed films were brittle and fragmented easily. On the other hand, concentration of PEG and PG higher than 30%posed problems in drying the films. Moreover, the formed films were sticky, difficult to handle and remove from the petri dish.

Fig.2 Effect of plasticizers on disintegration time and folding endurance. (Upendra C Galgatte, et al., 2013)

Fig.2 Effect of plasticizers on disintegration time and folding endurance. (Upendra C Galgatte, et al., 2013)

Owning the most professional team, CD Formulation can bring the most professional plasticizer screening technical guidance for customers. If you have a requirement about our plasticizer screening for oral thin film, please contact us by phone or email, and our colleagues will reply to you within three working days.

References

- Maram Suresh Gupta, Tegginamath Pramod Kumar, et al. Orodispersible films: Conception to quality by design. Advanced Drug Delivery Reviews. 2021, Vol (178).

- F. Hirpara, Sujit Kumar Debnath, et al. Optimization & screening of different film forming polymers and plasticizers in fast dissolving sublingual film. International Journal of Pharmacy and Pharmaceutical Sciences. 2016, Vol (6):41-42.

- Upendra C Galgatte, Sunil S Khanchandani, et al. Investigation of Different Polymers, Plasticizers and Superdisintegrating Agents Alone and In Combination for Use In The Formulation Of Fast Dissolving Oral Films. International Journal of PharmTech Research. 2013, Vol (4):1465-1472.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services