Fast-Disintegrating Buccal Film Development

Inquiry

The fast-disintegrating buccal film is a film containing APIs that dissolves or disintegrates in the saliva remarkably fast, within a few seconds without the need for water or chewing. Fast-dissolving buccal film drug delivery system as an important new way of administering drugs, more and more studies on fast-disintegrating buccal films have been conducted in recent years, which has become a cutting-edge replacement for more traditional sorts of drug delivery systems. CD Formulation has continuously explored and established innovative fast-disintegrating buccal film development drug platforms, focusing on the development of various complex fast-disintegrating buccal film drug delivery systems to meet the needs of different types of drugs.

Why Develop Fast-Disintegrating Buccal Film?

- The fast-disintegrating buccal film is a film made of hydrophilic polymers that dissolve quickly in the mouth to deliver drugs into the systemic circulation for their effects.

- It is easy to swallow, does not require water when administered, the patient takes the drug anytime and anywhere in any situation, and the dosage is accurate.

- The drug leaves minimal or no residue in the mouth after administration, there is no danger of choking and also provides a pleasant oral sensation.

- The fast-disintegrating buccal film has become an advanced alternative to traditional tablets, capsules, and liquids, and the film is similar in size, shape, and thickness to a postage stamp for easy portability.

- There is no contact between the medicine and the GI tract or acidic environments, the drug is preserved from degradation.

Our Fast-Disintegrating Buccal Film Formulation Development Services

As a global leader in oral thin film development, CD Formulation has extensive experience in the development of fast-disintegrating buccal film formulation development, our team of experts is familiar with the relevant regulatory requirements of fast-disintegrating buccal film and will take into account any problems in the development process of fast-disintegrating buccal film formulation for customer, and customer does not need to think about any problems in the development process.

Formulation Design

The formulation design phase is critical in determining the basic structure of fast-dissolving buccal film for optimal drug release. In the formulation design process, our team of experts focuses on API-excipient interaction studies,

etc.

Preparation Method Screening

The preparation methods of the fast-disintegrating buccal film have solvent casting, hot-melt extrusion, semisolid casting, solid dispersion extrusion, etc. When selecting the preparation method, we select the appropriate casting method based on the properties of the raw materials and excipients. In addition, we adjust as necessary to achieve repeatable, uniform content and consistent film thickness.

Quality Control

In the quality control phase, we performed various tests, including disintegration time, tensile strength, folding endurance, in-vitro dissolution, and drug release studies to assess the performance of a fast-disintegrating buccal film.

Packing

Due to the particularity of fast-disintegrating buccal film, it is easy to absorb moisture, we will customize the packaging according to the customer's needs and choose the right material to avoid the film being affected by environmental conditions.

Our Platforms for Fast-Disintegrating Buccal Film Formulation Development

| Technologies & Platforms |

Specifics Contents |

| Solvent Casting Technology Platform |

Solvent casting is the most used preparation technology. The process is to dissolve or suspend film-forming materials, raw materials, and other auxiliary materials in suitable solvents, such as water, ethanol, acetone, etc. The air bubbles are removed after mixing evenly, and then cast on the mold or coated with film forming agent and cut and package after drying. |

| Hot-Melt Extrusion Technology Platform |

Hot melt extrusion, which does not require the use of solvents during the production process, shapes a mixture of polymers, drugs, and other excipients into a film by melting all the components. This technology is often used to prepare solvent-free oral thin films. |

| Semi-Solid Casting Technology Platform |

The water-soluble film-forming polymer solution is made using this procedure. The resultant solution is mixed with an acid-insoluble polymer solution (Examples: cellulose acetate butyrate, cellulose acetate phthalate). The right quantity of plasticizer is then added to create a gel mass. Using heat-controlled drums, this gel mass is subsequently cast into the films or ribbons. The films should be between 0.015 and 0.05 inches thick. The ratio of film-forming polymer to acid-insoluble polymer should be 1:4. |

| Solid Dispersion Extrusion Technology Platform |

The solid dispersion has become an established solubilization technology for poorly water-soluble drugs. This technology is often used to prepare oral-soluble films containing insoluble APIs. |

Our Advantages in Fast-Disintegrating Buccal Film Development

- Professional Teams : The mechanical properties of the film are an important factor to consider in fast-disintegrating buccal film formulation development, with special consideration given by our team of experts to lower glass transition temperatures and the screening of excipients, etc.

- Reliable Excipients Suppliers : We have a team that is familiar with legal regulation, and our team will screen the excipients used in the fast-disintegrating buccal film formulation from a regulatory perspective and ensure that the excipients selected are safe.

- Tailored Solutions : Formulation of the fast-disintegrating buccal film involves the application of both aesthetic and performance characteristics such as strip-forming polymers, plasticizers, APIs, sweetening agents, saliva stimulating agents, flavoring agents, coloring agents, stabilizing and thickening agents, masking agents, rapid dissolution, physical appearance, taste, etc. We offer customized solutions, working closely with our customers to understand their needs and develop tailor-made solutions to meet their unique specifications.

- One-stop Solutions : We provide one-stop solutions for fast-disintegrating buccal film, with high-cost performance and competitive prices.

Published Data

Technology: Solvent casting technique

Journal: European Journal of Pharmaceutical Sciences

IF: 5

Published: 2020

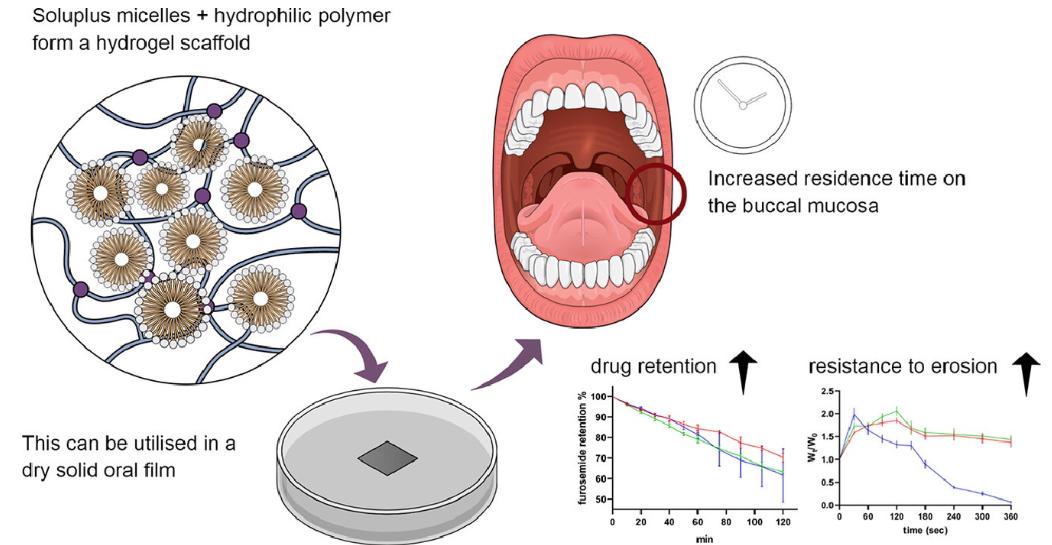

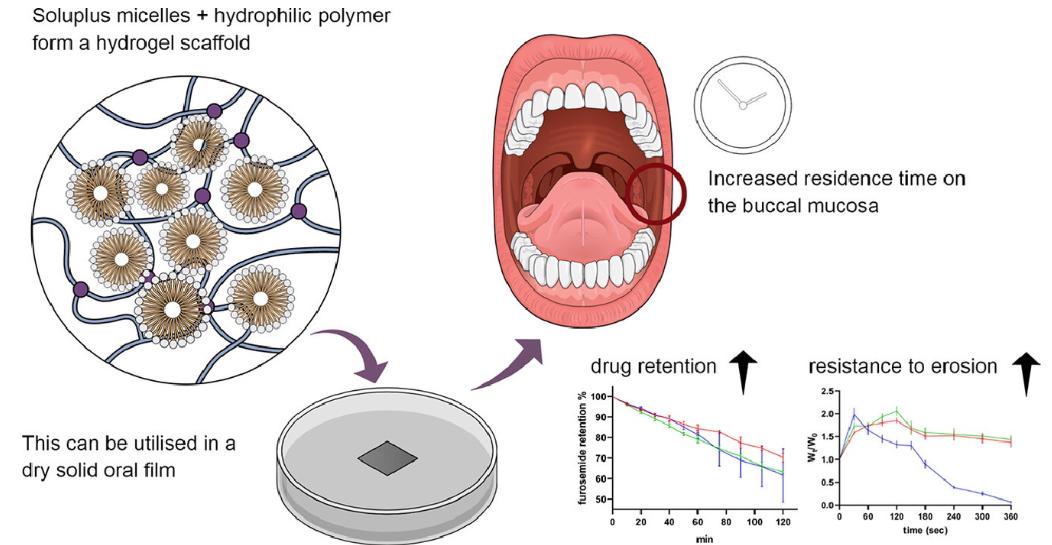

Results: The novel buccal delivery system investigated in this study combines the solubilization and nanocarrier capabilities of Soluplus®, with the mucoadhesive properties of an additive polymer, that allow prolonged contact with the mucosal surface, in a dry and user-friendly oral film.

Fig.1 Mucoadhesive buccal films based on a graft co-polymer - A mucin-retentive hydrogel scaffold. (Julia F. Alopaeus, et al., 2020)

Fig.1 Mucoadhesive buccal films based on a graft co-polymer - A mucin-retentive hydrogel scaffold. (Julia F. Alopaeus, et al., 2020)

CD Formulation specializes in the development of various oral thin films and has rich experience in the development of fast-disintegrating buccal film drug delivery system. If you have any requests for our fast-disintegrating buccal film services, please contact us by phone or email, our colleagues will reply to you within three working days.

References

- Apoorva Mahajan, Neha Chhabra, et al. Formulation and Characterization of Fast Dissolving Buccal Films. Der Pharmacia Lettre. 2011, 3(1): 152-165.

- S. M. Shahidulla1, Ayesha Begum, et al. BUCCAL FILM: AN UPDATED OVERVIEW. INTERNATIONAL JOURNAL FOR INNOVATIVE RESEARCH IN MULTIDISCIPLINARY FIELD. 2022, Vol (8): 132-140.

- Julia F. Alopaeusa, Marie Hellfritzsch, et al. Mucoadhesive buccal films based on a graft co-polymer - A mucin-retentive hydrogel scaffold. European Journal of Pharmaceutical Sciences. 2020, Vol (142).

- Angela Abruzzo, Beatrice Vitali, et al. Mucoadhesive Buccal Films for Local Delivery of Lactobacillus brevis. Pharmaceutics. 2020:2-19.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services