3D Printing Service of Oral Thin Film

Inquiry

3D printing technology has been used to develop new and complex drug delivery systems that are nearly impossible to produce by adopting traditional formulation techniques. This technology has shown good application prospects in the development and production of oral thin films, which can be used to produce oral thin films with multilayers of active pharmaceutical ingredients (APIs) that can be personalized according to the needs of patients. CD Formulation has extensive experience in 3D printing of oral thin film, providing a more uniform amorphous drug distribution than other casting methods, and we can also use 3D printing to adjust the dosage of drugs according to the patient's health condition.

Advantages of 3D Printing Oral Thin Films

- 3D printing can be based on the patient's condition and needs to superimpose the layers of oral thin films to accommodate more APIs per unit area, solves the problems of size limitation, low drug load, sensitivity to temperature changes and mechanical stress sources of conventional oral thin films.

- 3D printing can adjust the drug dose according to the patient's health condition, controlling drug release over a longer period, thus reducing the frequency of dosing.

- 3D printing can subdivide oral thin films into different active layers as well as excipient layers, which can be based on the patient's condition and needs to superimpose the layers of oral thin films to accommodate more APIs per unit area.

- 3D printing can indeed produce insoluble oral thin films polymers, which makes this new drug delivery system more promising.

Our Workflow of 3D Printing Oral Thin Films

Selecting of 3D Printing Method for Oral Thin Films

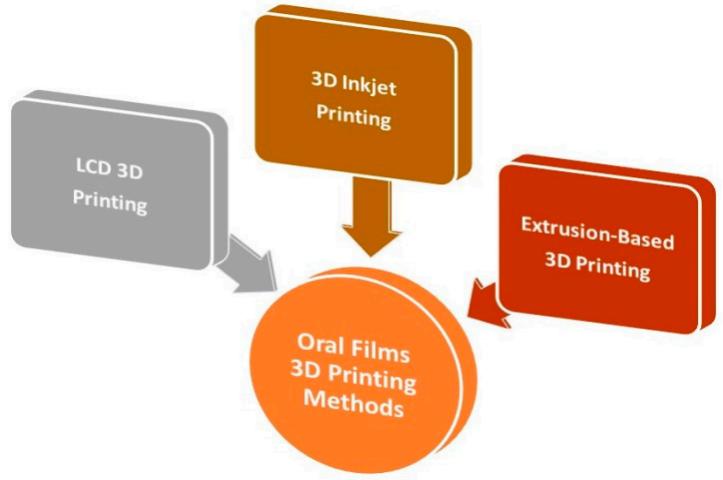

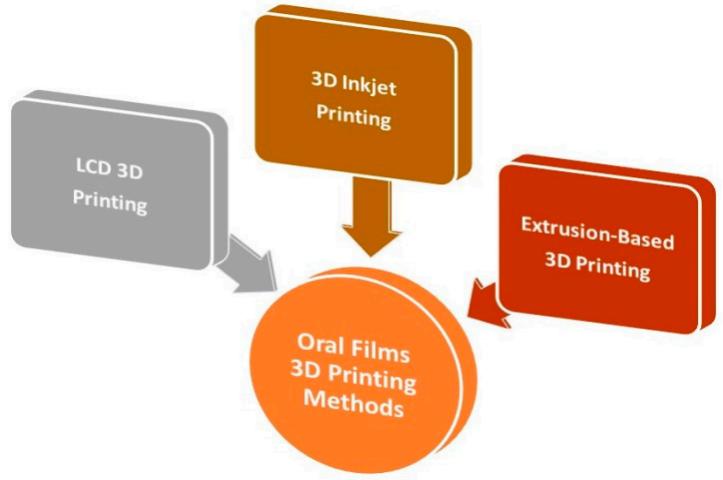

Printing methods for oral thin films have 3D inkjet printing, fused deposition modeling (FDM), pressure-assisted microsyringe (PAM)/semisolid extrusion (SSE), direct powder extrusion (DPE) and liquid crystal display (LCD) 3D printing. We will select the best printing method based on the expected cost of the customer, the object to be printed, the viscosity of the starting material, the type of polymer, the Properties of the APIs, etc.

Fig.1 Three-dimensional printing methods for oral films. (Patil, V.G., et al., 2020)

Fig.1 Three-dimensional printing methods for oral films. (Patil, V.G., et al., 2020)

Screening of Polymers for 3D Printing

Common synthetic polymers used in 3D printing have polycaprolactone (PCL), polylactic acid (PLA) and polylactic acid-glycolic acid (PLGA), polyethylpyrrolidone (PVP), polyvinyl alcohol (PVA), and based on ABS, hydroxy propyl methyl cellulose (HPMC) and carboxymethyl cellulose (CMC), these polymers are characterized by high printability and mechanical strength. Polymers play a crucial role in the manufacture of 3D printing of oral thin films. Therefore, the selection of the right polymer is crucial for a high-quality oral thin film. Our technical team will select the appropriate polymer based on the customer's APIs and the printing method chosen, etc.

Morphological Analysis

Morphological analysis of the surface of filaments and 3D printed films is performed using scanning electron microscopy to determine surface properties and observe any defects or irregularities in the structure.

Disintegration Studies and In Vitro Drug Release Study of the Films in Simulated Saliva

The disintegration of the released drug was studied by placing the sample into a beaker containing simulated saliva and under magnetic agitation.

Our Platforms for 3D Printing Oral Thin Films

| Technologies & Platforms |

Specifics Contents |

| FDM Technology Platform |

FDM is one of the most popular techniques in 3D printing. Create 3D printing structures according to CAD geometry by depositing thermoplastic filaments layer by layer and extruding them through a nozzle (melted or softened). |

| 3D Inkjet Printing Technology Platform |

3D inkjet printing is an extension of traditional inkjet printing, limited to single-layer coating. |

| PAM/SSE Technology Platform |

PAM/SSE uses sticky and semi-solid materials to make microsyringes. It uses compressed air to extrude a semi-solid material, resulting in a 3D-printed microstructure. |

| DPE Technology Platform |

DPE avoids the initial filament manufacturing of hot melt extrusion (HME). As a result, production costs are greatly reduced, formulation development is accelerated, and attention is shifted to a single 3D printing process. |

| LCD 3D Printing Technology Platform |

LCD 3D printing is an emerging technology with low equipment cost. It is one of the three light-cured 3D printing technologies available today. |

Our Advantages in 3D Printing Oral Thin Film

- Advanced Technology: We have a variety of 3D printing technology platforms, and we can choose printing methods according to customer requirements.

- Expertise: Proven research portfolio solutions and expert teams in 3D printing oral thin films development.

- Flexibility: Collaborative and customized project design successful project execution.

- Professional Team: We have a dedicated technical team ensuring that every aspect of the 3D printing services we provide meets the highest scientific standards.

Published Data

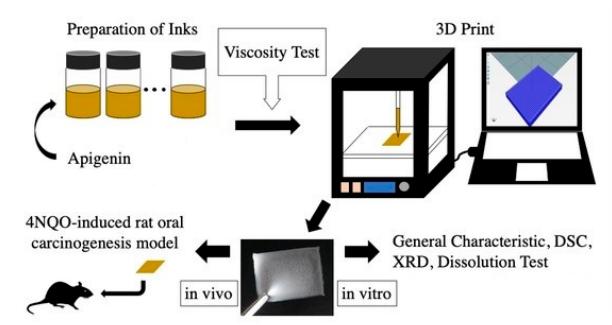

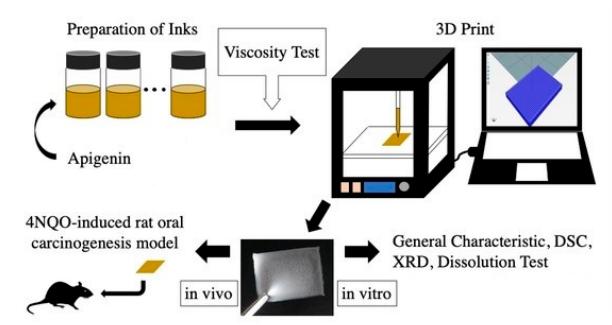

Technology: 3D Printing technique

Journal: Processes

IF: 3.5

Published: 2023

Results: In this research, using apigenin as an API, obtained 3D-printed MBFs for oral leucoplakia, proving their chemopreventive effects on oral cancer in vivo on rats. The MBFs contain polymers (HPMC, CARBOPOL, and Poloxamer), water and ethanol for apigenin solubilization. The printer ink's suitable viscosity was adjusted, leading to the thriving manufacturing of the 3D-printed oral mucoadhesive films.

Fig.2 Overview of preparation, physicochemical, pharmacotechnical, and anticancer properties of 3D-printed mucoadhesive buccal films with apigenin. (Emma Adriana Ozon, et al., 2023)

Fig.2 Overview of preparation, physicochemical, pharmacotechnical, and anticancer properties of 3D-printed mucoadhesive buccal films with apigenin. (Emma Adriana Ozon, et al., 2023)

As a leader in the development of new drugs, CD Formulation is committed to applying 3D printing technology to the development and production of oral thin films to promote the development of the drug delivery field. If you have a requirement about our 3D printing service of oral thin film, please contact us by phone or email, our colleagues will reply to you within three working days.

References

- Emma Adriana Ozon, Iulian Sarbu, et al. Three-Dimensional Printing Technologies in Oral Films Manufacturing—A Minireview. Processes. 2023: 2-19.

- Patil, V.G.; Mahaparle, S, et al. 3D Printing: Opportunities and Challenges. J. Emerg. Technol. Innov. Res. 2020, 7: 828–836.

- Touraj Ehtezazi1, Marwan Algellay1, et al. Next Steps in 3D Printing of Fast Dissolving Oral Films for Commercial Production. Recent Patents on Drug Delivery & Formulation. 2020: 5-20.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services