Nanogel Development for Nanomedicine

Inquiry

Nanogel offers benefits such as its small size, ability to be engulfed by cells, and capacity to pass through protective membranes in the human body, facilitating drug delivery to the brain and efficient drug loading. As a result, nanogel is extensively utilized in drug delivery. CD Formulation offers our professional nanogel development services for nanomedicines to cater to diverse needs through our cutting-edge nanogel preparation techniques.

Classification and Advantages of Nanogels as Drug Delivery Carriers

Nanogels are three-dimensional hydrogel materials with sizes ranging from 1 nm to 1000 nm formed by cross-linking swellable naturally occurring and/or synthetic polymer networks. Nanogels possess the properties, such as small size, porosity, amphiphilicity, softness, high degradability, high biocompatibility, etc. According to the phase change triggering mechanism of nanogels, nanogels can be divided into ordinary nanogels and stimuli-responsive nanogels.

Ordinary Nanogels

Ordinary nanogels will swell when absorbing water, and their drug administration and subsequent release behavior will be single.

Stimuli-Responsive Nanogels

Stimuli-responsive nanogels will swell or fully dissolve when exposed to different environments, and their drug administration and subsequent release behavior will be more intelligent. This type of nanogels include thermo-responsive nanogels, pH-responsive nanogels, magnetic-responsive nanogels, ultrasound-Responsive nanogels, etc.

Thermo-Responsive Nanogels

Thermo-responsive nanogels contain hydrophobic and hydrophilic groups, and their gelling behavior is related to the interaction between different groups and water.

pH-Responsive Nanogels

Three-dimensional structure of pH-responsive nanogels consists of anionic or cationic groups that can undergo protonation or deprotonation. Anionic groups such as carboxylic acid or sulfonic acid groups are present, while cationic groups typically feature terminal amino groups.

Magnetic-Responsive Nanogels

We constructed hybrid nanogels using magnetic nanoparticles (MNPs) and temperature-sensitive nanogels, and loaded the chemical drug DOX (DOX-MagNanogel).

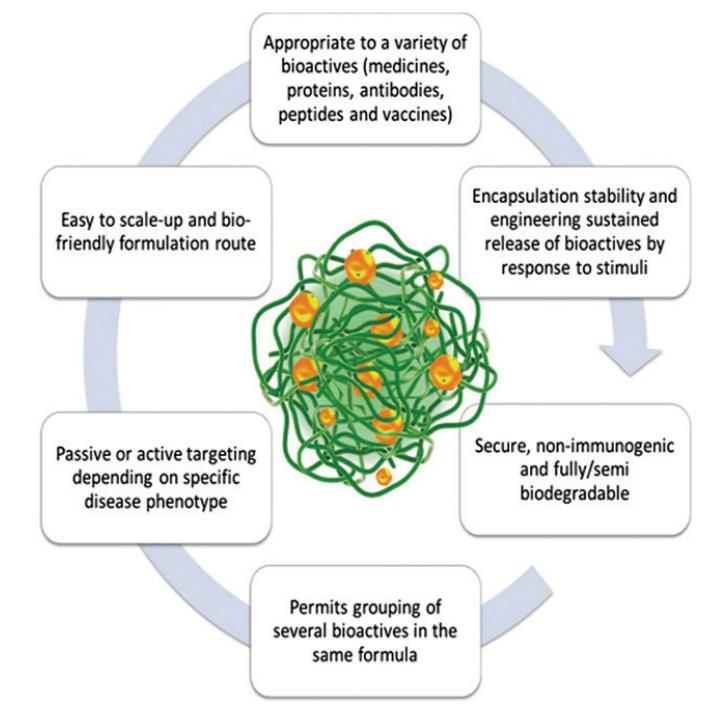

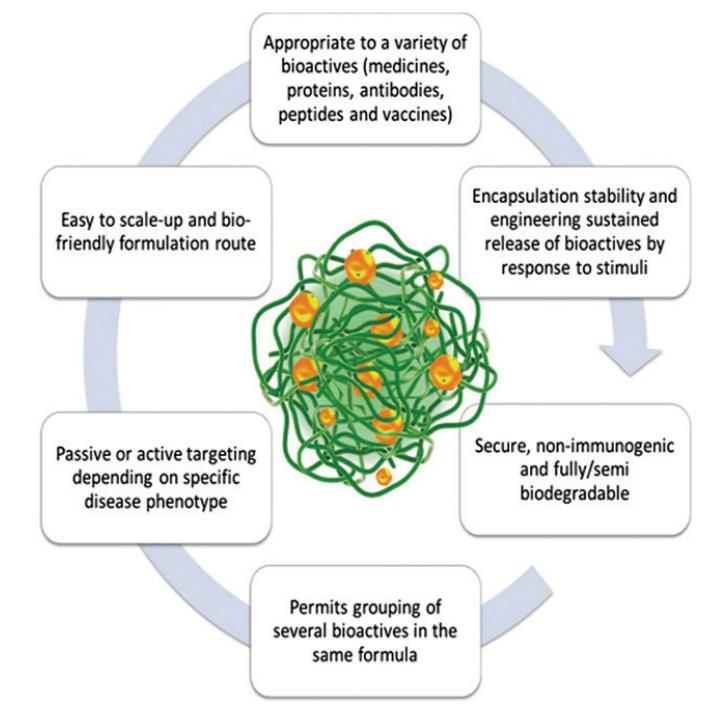

Nanogels can also be designed to have a core-shell or core-shell-corona structure, as well as contain spherical or various other shape types of nanoparticles and are widely used in therapeutic areas with different routes of administration. Here are potential advantages of nanogels as follows.

Fig.1 Schematic illustration of potential advantages of nanogel formulations. (Iordana Neamtu, et al. 2017)

Fig.1 Schematic illustration of potential advantages of nanogel formulations. (Iordana Neamtu, et al. 2017)

Explore Our Preparation Methods of Nanogels

The carrier materials used to prepare nanogels mainly include acrylic acid, acrylamide, polysaccharide and pluronic acid, cationic polyethylenimine, polyvinyl alcohol, polyvinylpyrrolidone and polylactic acid, etc. Nanogels are formed by physical or chemical cross-linking of carrier materials. Physical cross-linking occurs through non-covalent bonds, while chemical cross-linking occurs through covalent bonds. CD Formulation is committed to the research of nanogel preparation technology for many years. We can provide our customers with nanogel preparation technology based on physical or chemical cross-linking.

Physical Cross-Linking

Physically cross-linked nanogels are supramolecular particles composed of polymer molecules formed by noncovalent interactions. After we mixed the polymers in aqueous solution, they will be cross-linked through hydrogen bonds, van der Waals forces, hydrophobic forces and electrostatic interactions to form nanogels.

Chemical Cross-Linking

This method is the most advanced and more versatile method for preparing nanogels. Chemical cross-linking methods include inverse emulsion polymerization, reversible addition-fragmentation chain transfer (RAFT), click chemical cross-linking, and photo-induced cross-linking. Our main process of free radical polymerization is to dissolve free radical initiators, monomers and stabilizers in a homogeneous or heterogeneous system. The free radical initiator initiates the polymerization of the monomers to form a three-dimensional network of nanogels.

Inverse Emulsion Polymerization

This process involves a polymerization reaction that starts by continuously emulsifying a water-in-oil emulsifier in the oil phase. The size of nanogels can be controlled by different factors like surfactant, monomer, and cross-linker ratios, as well as pH levels.

Reversible Addition-Fragmentation Chain Transfer (RAFT) Polymerization

Using RAFT, the polymer goes through a sequence of reactions involving disulfide compounds, such as reversible addition, reversible degradation of the adduct, and chain transfer reactions, to regulate the polymer's molecular weight in the free radical polymerization process. This technology has the capability to alter the micelle structure of amphiphilic polymers by adjusting the length, structure, and characteristics of the polymer.

Click Chemistry Cross-linking Polymerization

One more method for preparing nanogels that we can provide is through click chemistry, which involves the use of copper(I)-catalyzed azide-alkyne (CuAAC) click reaction, copper-free click reaction, and pseudo-click chemistry.

Photo-Induced Crosslinking Polymerization

During the irradiation process, water molecules decompose into hydroxyl radicals and hydrogen atoms, potentially converting the polymer into micro-based substances, resulting in intermolecular cross-linking and promoting the formation of nanogels.

We also explored other chemical cross-linking methods for nanogels, including copper-catalyzed click chemistry reactions of azides and alkynes, Michael addition of thiols and α,β-unsaturated carboxyl groups such as acrylates and maleimides, Schiff base reaction of aldehydes with amines or acyl fats, thiol-disulfide exchange reaction, amide cross-linking of amines and carboxylic acids or activated esters, enzymatic cross-linking of thiols, etc.

Our Analytical Capabilities for Nanogels

The phase transition and rheological behavior of nanogels are characterized by monitoring particle size, zeta potential, etc. CD Formulation can provide our clients with the following characterization services for nanogels.

- Particle Size and Distribution

- Surface Morphology

- Zeta potential

- Drug Content

- Composition and Structure of Nanogels

- In Vitro Drug Release

Why Choose Us to Develop Nanogels?

- We have a skilled research and development team with extensive expertise in tailoring nanogels. Apart from regular nanogels, we can create various types of stimuli-responsive nanogels for clients, such as those sensitive to temperature, pH, magnetic fields, ultrasound, etc.

- We also are committed to exploring nanogel fabrication technology including physical and chemical cross-linking, such as inverse emulsion polymerization, reversible addition-fragmentation chain transfer polymerization, click chemical cross-linking polymerization, and photo-induced cross-linking polymerization.

- We can explore the phase transition and rheological behavior of nanogels by monitoring particle size, zeta potential, morphology, in vitro drug release, etc.

Published Data

Technology: Ainverse miniemulsion technique for ntimicrobial quaternized chitosan/Ag composite nanogels (QCS/Ag CNGs) preparation

Journal: Carbohydrate Polymers

IF: 11.2

Published: 2022

Results:

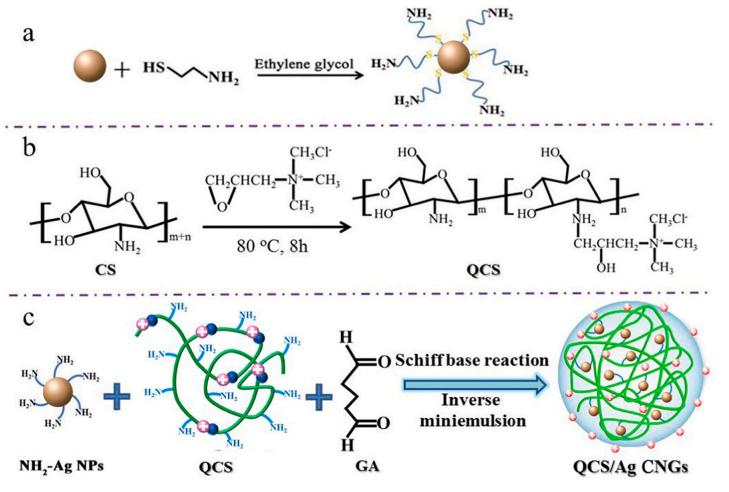

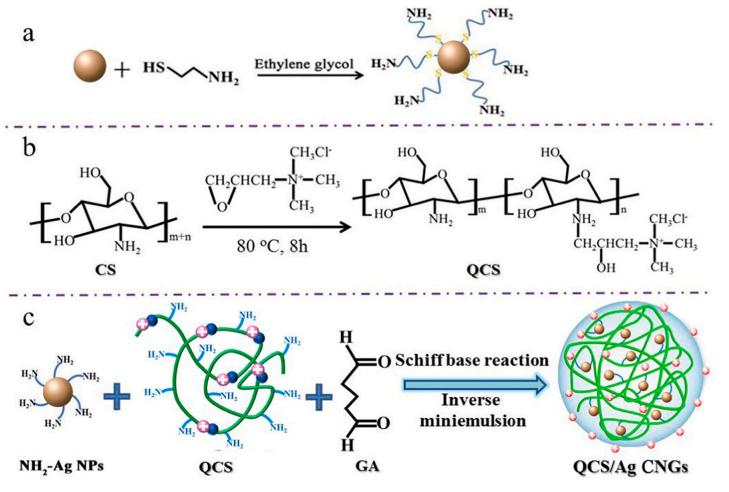

The authors prepared antibacterial quaternized chitosan/Ag composite nanogels (QCS/Ag CNGs) with tunable properties through inverse miniemulsion technology, with high encapsulation efficiency of NH2 -Ag nanoparticles (NPs). Through the synergistic sterilization of Ag NPs and QCS, QCS/Ag CNGs possess excellent broad-spectrum antibacterial activity and low biotoxicity.

The synthesis of NH2-Ag NPs and QCS, and preparation of QCS/Ag CNGs was shown in Fig. 2.

Fig.2 Synthetic routes of (a) NH2-Ag NPs and (b) QCS. (c) Preparation of QCS/Ag CNGs in inverse miniemulsions. (Feng Gao, et al. 2022)

Fig.2 Synthetic routes of (a) NH2-Ag NPs and (b) QCS. (c) Preparation of QCS/Ag CNGs in inverse miniemulsions. (Feng Gao, et al. 2022)

As your partner, CD Formulation can wholeheartedly advise you on nanogel formulation development services and develop products that meet your requirements. If you need to consider our services, please feel free to contact us for your details.

References

- Iordana Neamtu, Alina Gabriela Rusu, Alina Diaconu, et al. Basic concepts and recent advances in nanogels as carriers for medical applications. Drug Delivery.2017,24(1): 539-557.

- Feng Gao, Yifang Mi, Xinlei Wu, et al. Preparation of quaternized chitosan/Ag composite nanogels in inverse miniemulsions for durable and antimicrobial cotton fabrics. Carbohydrate Polymers. 2022,278,118935.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig.1 Schematic illustration of potential advantages of nanogel formulations. (Iordana Neamtu, et al. 2017)

Fig.1 Schematic illustration of potential advantages of nanogel formulations. (Iordana Neamtu, et al. 2017) Fig.2 Synthetic routes of (a) NH2-Ag NPs and (b) QCS. (c) Preparation of QCS/Ag CNGs in inverse miniemulsions. (Feng Gao, et al. 2022)

Fig.2 Synthetic routes of (a) NH2-Ag NPs and (b) QCS. (c) Preparation of QCS/Ag CNGs in inverse miniemulsions. (Feng Gao, et al. 2022)