Crystallinity Testing Service for Nanoformulations

Inquiry

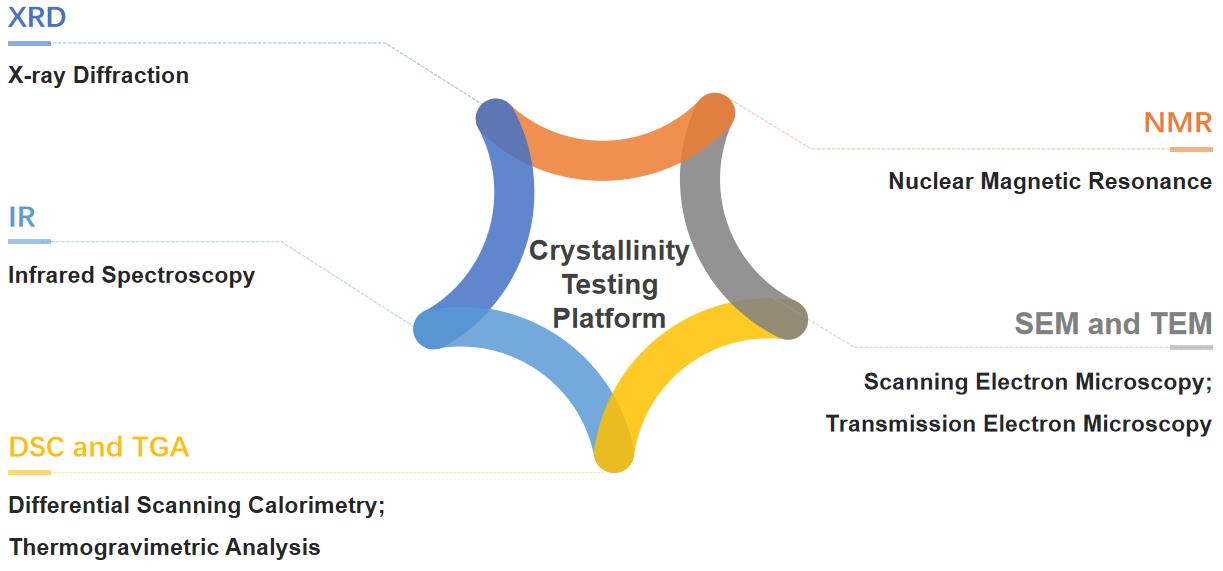

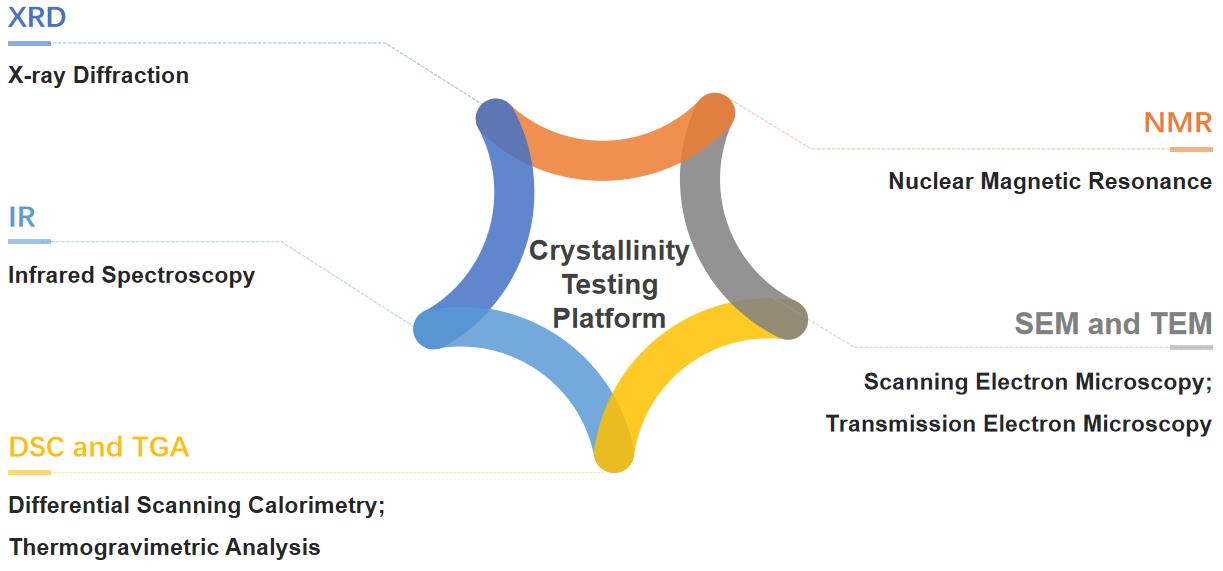

The crystallinity of nanomedicine is the percentage of the weight or volume of the crystallized part to the total weight or volume. It is a key physical parameter that has an important impact on the performance and application of nanocarrier materials. Therefore, accurate determination of crystallinity is of great significance for the research and application of nanocarrier materials. CD Formulation can offer the crystallinity of nanoformulations testing services utilizing different testing methods such as XRD, DSC, NMR, etc.

Why is Nanoformulation Crystallinity Testing Important?

The crystallinity of APIs or nanocarrier drugs is of great significance in the pharmaceutical industry.

First of all, crystallinity represents high purity, which can eliminate the interference of impurities on drug activity and ensure the reliability of drug efficacy.

Secondly, crystallinity is closely related to crystal form, and different crystal forms have different biological activities. By controlling the crystallinity, the appropriate crystal form can be selected to achieve the purpose of regulating drug activity.

In addition, crystallinity is also related to the physical properties of the drug, such as solubility, dissolution rate, etc., which directly affects the absorption, distribution and metabolism of the drug.

Meanwhile, it is important to determine the crystallinity of nanoparticles, for example, lipids and encapsulated drugs may undergo polymorphic transformation during storage, leading to drug extrusion and instability. Lipid crystallinity also strongly affects drug loading and drug release. Therefore, our R&D team is committed to researching the nanoproperty characterization of nanomedicines including the crystallinity of nanocarrier materials.

Our Nanoformulation Crystallinity Testing Platform

With the help of our advanced equipment and creative analytical design concept, we have set up our special and strong crystallinity of nanoformulation testing platform.

Fig. 1 Our crystallinity of nanoformulation testing platform. (CD Formulation)

Fig. 1 Our crystallinity of nanoformulation testing platform. (CD Formulation)

Our Nanoformulation Crystallinity Testing Techniques

CD Formulation explores and researches nanoformulation crystallinity testing techniques including X-ray diffraction (XRD), density method, infrared spectroscopy, and differential scanning calorimetry (DSC), etc. We always select an appropriate crystallinity testing method based on specific research purposes, sample properties, and experimental conditions.

X-ray Diffraction Method (XRD)

The total scattering intensity measured by this method is the sum of the scattering intensity of materials in the entire space and is only related to the intensity of the primary ray, the chemical structure, and the total number of electrons participating in diffraction, that is, the mass. Crystallinity is the ratio of scattering from the crystalline part to the total intensity of scattering.

Density Method

It is assumed that in a crystalline polymer, crystalline and amorphous parts coexist. If the density of the completely crystalline polymer (ρc) and the density of the completely amorphous polymer (ρa) can be measured, the crystallinity of the sample can be obtained according to the two-part coexistence model.

Infrared Spectroscopy

The infrared spectrum of crystalline polymers has a specific crystallization-sensitive absorption band (crystalline band), and its intensity is also related to the degree of crystallinity. As the crystallinity increases, the intensity of the crystal band increases. On the contrary, if the non-crystalline part increases, the amorphous absorption band increases. This crystal band can be used to determine the crystallinity of the crystalline polymer.

Thermal Analysis Methods

Our commonly used thermal analysis methods include Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA). These methods evaluate crystallinity by measuring the thermal behavior of the material as it is heated. Materials with high crystallinity have higher melting points and thermal stability.

Nuclear Magnetic Resonance (NMR) Absorption Method

Nuclear magnetic resonance is a method of obtaining crystallinity information by measuring the magnetic resonance signals of atomic nuclei in nanocarrier materials. Nanocarrier materials with different crystallinity levels will show different NMR spectral characteristics. We use NMR methods to provide quantitative information on crystallinity and have high applicability to amorphous materials and liquid crystal materials.

Microscopy Methods

Microscopy methods include optical microscopy, scanning electron microscopy (SEM), and transmission electron microscopy (TEM). These methods evaluate the crystallinity of a material by observing its microstructure. Optical microscopes can be used to observe the morphology and grain size of crystals. SEM and TEM can provide higher-resolution images and can observe the grain boundaries and defects of crystals. Crystallinity can be quantitatively assessed by analyzing the grain boundary density and grain size distribution of crystals.

In addition to the above methods, we also use a thermal imaging camera to evaluate the crystallinity by measuring the thermal radiation of the nanocarrier materials.

Why Choose Us to Test Nanoformulation Crystallinity?

- Our laboratory has multiple advanced instruments and equipment for crystallinity analysis and research of nano-preparations, such as XRD, DSC, NMR, SEM, etc.

- We also established a crystallinity analysis platform to meet the needs of crystallinity analysis during the research process of nanoformulation.

- Our R&D team has rich experience in developing and calculating the crystallinity of nanoformulation for many years, and they have explored a variety of crystallinity testing methods for nanoformulations, including XRD, DSC, TGA, SEM, etc.

Published Data

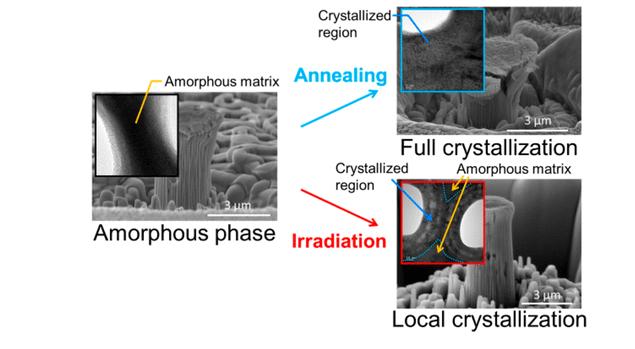

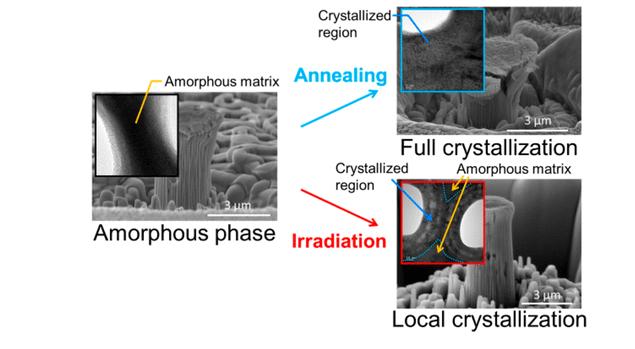

Technology: Crystallinity detection technology

Journal: Nano Letters

IF: 10.8

Published: 2019

Results:

The authors studied the emergence of metalloid plasticity through crystallinity control in monolithic zirconia with a vertically aligned honeycomb-like periodic nanopore structure fabricated using anodization techniques. After heat treatment and/or proton irradiation, the crystal order of nanoporous zirconia films changes between monoclinic, tetragonal and amorphous phases, while the vertical pore structure is maintained. These results benefit from tunable structural stability and provide new opportunities for nanoporous ceramic materials for various applications.

Fig.2 Crystallinity control in nanoporous process. (Jung Woo Kim, et al. 2019)

Fig.2 Crystallinity control in nanoporous process. (Jung Woo Kim, et al. 2019)

CD Formulation has multiple analytical equipment and a strong team and can provide you with crystallinity testing services for your nanoformulation development. If you need any assistance with crystallinity testing in formulations, please contact us at any time.

References

- Jung Woo Kim, Dahye Shin, Yang Jeong Park, et al. Ductilization of Nanoporous Ceramics by Crystallinity Control. Nano Letters. 2019, DOI: 10.1021/acs.nanolett.9b02838.

How It Works

STEP 2

We'll email you to provide your quote and confirm order details if applicable.

STEP 3

Execute the project with real-time communication, and deliver the final report promptly.

Related Services

Fig. 1 Our crystallinity of nanoformulation testing platform. (CD Formulation)

Fig. 1 Our crystallinity of nanoformulation testing platform. (CD Formulation) Fig.2 Crystallinity control in nanoporous process. (Jung Woo Kim, et al. 2019)

Fig.2 Crystallinity control in nanoporous process. (Jung Woo Kim, et al. 2019)