Thermoresponsive Peptide & Protein Hydrogel Development

InquiryAt CD Formulation, our process for developing temperature-responsive peptide and protein hydrogels is rooted in a multidisciplinary approach that combines formulation science, material engineering, and advanced analytical techniques. We can tailor the hydrogel properties to meet specific needs, such as desired gelation temperature, drug release kinetics, and mechanical properties.

Thermoresponsive Hydrogels for Drug Delivery

Thermoresponsive hydrogels (TRHs), also known as temperature-sensitive hydrogels, undergo volume changes and sol-gel transitions in response to temperature. An important feature of this type of gel is that it is a solution below the lower critical solution temperature (LCST) and forms a gel above the LCST. TRHs can quickly locate drugs at local injection sites and avoid drug loss, thereby improving treatment efficiency and reducing adverse reactions to normal cells and tissues. This makes TRHs have good application prospects in the field of drug delivery.

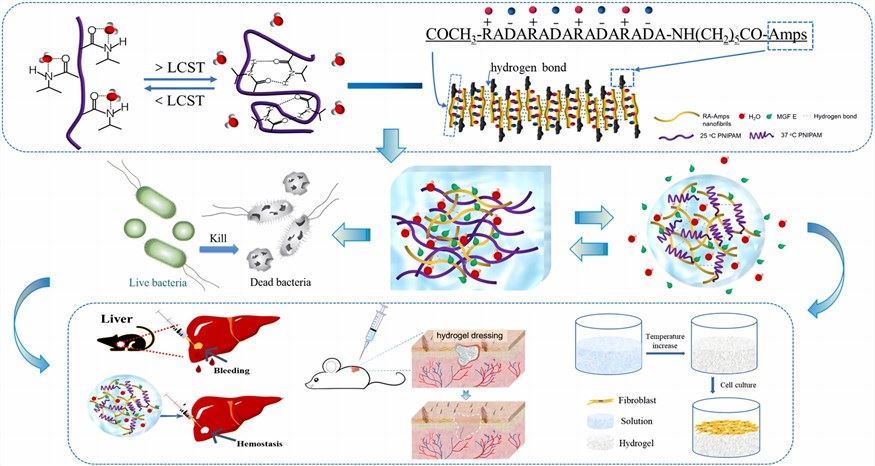

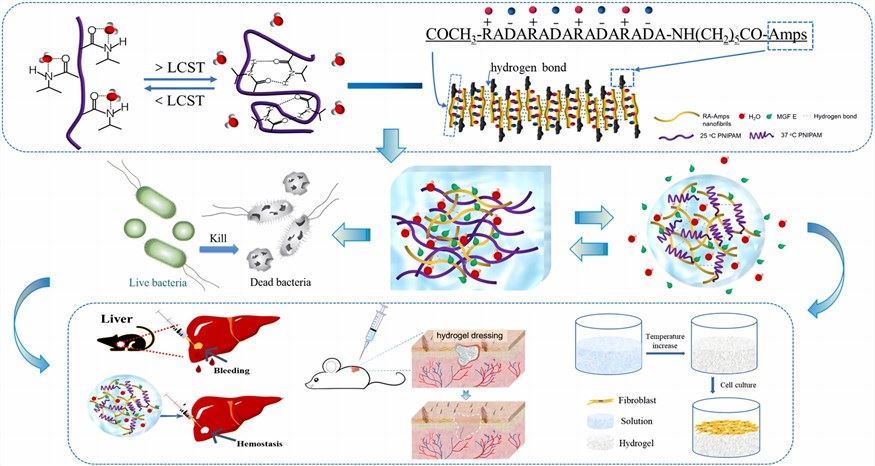

Hydrogel with a self-assembled peptide coupled with an antimicrobial peptide (Feng T.; et al. 2022)

Hydrogel with a self-assembled peptide coupled with an antimicrobial peptide (Feng T.; et al. 2022)

Our Peptide & Protein TRHs Development Process

-

Materials Selection

Identify optimal thermo-responsive polymers and monomers based on target gelation temperature.

-

Synthesis Optimization

Use controlled polymerization to achieve defined macromer composition, architecture and functionality.

-

Peptide/Protein Loading

Establish an optimal method to incorporate protein into hydrogel network pre- or post-gelation.

-

Gelation Optimization

Characterize and refine the sol-gel transition based on physiological temperature.

-

Formulation Optimization

Maximize peptide/protein stability and tailor the release profile.

-

Characterization

Analyze critical quality attributes including gelation kinetics, mechanics, and morphology.

Our Materials for Peptide and Protein TRHs Development

| Types |

Chitosan (CS) |

Poly (N-isopropylacrylamide) (PNIPAM) |

Poloxamer |

| <LCST |

CS with free amino groups can embed negatively charged peptide/protein molecules through electrostatic interaction. |

The amide group in the PNIPAM polymer chain forms a strong hydrogen bonding force with the surrounding water molecules, showing a stretched state. |

Poloxamers are PEO-PPO-PEO triblock copolymers composed of polyoxyethylene (PEO) and polyoxypropylene (PPO).

Different ratios of PEO and PPO result in different gelling temperatures. |

| >LCST |

Controlled by hydrophobic interactions and hydrogen bonds, the CS system forms a hydrogel and releases drugs. |

The hydrophilic effect in the PNIPAM molecular chain weakens, the molecular chain changes from loose to tight, and the drug is released. |

The poloxamers system undergoes a reversible sol-gel transition to release the drug. |

Applications of Peptide & Protein TRHs We Developed

- Ocular Drug Administration

We can help customers develop TRHs for ocular delivery to treat glaucoma, damage repair, age-related macular degeneration, diabetic retinopathy, etc. The temperature-sensitive ophthalmic gel has sustained drug release characteristics, which can significantly extend the residence time of drugs in the eye, enhance drug absorption in the aqueous humor, and improve ocular bioavailability. Meanwhile, there is no obvious irritation in the cornea, conjunctiva or iris after simultaneous administration, and it is relatively safe.

- Oral Mucosal Drug Delivery

Temperature-sensitive hydrogels are suitable for oral administration, especially local administration to the oral mucosa. We adjust the gelling temperature of the hydrogel by optimizing the formula and process to adapt it to the temperature of the human oral cavity (36-37°C). TRHs can adhere strongly to the mucosa or gum surface in the oral cavity, have a long local stay time and a quick onset of effect, and are suitable for oral ulcers, gingivitis, periodontitis and other oral diseases.

Vaginal drug delivery is usually based on temperature-sensitive hydrogels. Based on the properties of the peptide or protein, we select appropriate temperature-responsive materials, such as poloxamer and hydroxypropyl-β-cyclodextrin, to prepare temperature-sensitive hydrogels suitable for vaginal administration. By adjusting the gelling temperature, rheological characteristics and mucosal adhesion strength of TRH, it can quickly form a stable gel in the vaginal environment without obvious irritation.

Advantages of Our Peptide & Protein TRH Development Services

- Multidisciplinary experts in biomaterials science and engineering

- Customized hydrogel vehicles

- Comprehensive materials and formulation characterization

- Controlled release of peptides and proteins

- Protection of sensitive peptides and proteins

- In situ gelation triggered by body temperature

- Enhanced bioavailability

By partnering with CD Formulation, clients can leverage our expertise and infrastructure, eliminating the need to establish independent formulation capabilities. This not only saves resources but also provides access to specialized knowledge and facilities dedicated to temperature-sensitive hydrogel development. Contact us today to learn more about our temperature-sensitive peptide/protein hydrogel development services!

References

- Feng T.; et al. An injectable thermosensitive hydrogel with a self-assembled peptide coupled with an antimicrobial peptide for enhanced wound healing. J Mater Chem B. 2022, 10(32):6143-6157.

- Shang L.; et al. Peptide supramolecular hydrogels with sustained release ability for combating multidrug-resistant bacteria. ACS Appl Mater Interfaces. 2023, 15(22):26273-26284.

- Rocker A.J.; et al. Sulfonated thermoresponsive injectable gel for sequential release of therapeutic proteins to protect cardiac function after myocardial infarction. ACS Biomater Sci Eng. 2022, 8(9):3883-3898.

Related Services

Hydrogel with a self-assembled peptide coupled with an antimicrobial peptide (Feng T.; et al. 2022)

Hydrogel with a self-assembled peptide coupled with an antimicrobial peptide (Feng T.; et al. 2022)