Peptide & Protein Transdermal Patch Development

InquiryResearch and development of pharmaceutical formulations is the focus of CD Formulation. Through innovative transdermal patch technology, we advance biological drug delivery for our customers worldwide and provide efficient, safe, and easy-to-use formulation development services. In the field of transdermal patches containing peptides and proteins, we have extensive expertise and experience.

Why are Peptides/Proteins Made into Transdermal Patches?

Transdermal patches are thin adhesive devices applied to the skin that deliver drugs across the dermis for systemic absorption. When integrated with peptides, proteins or vaccines, patches offer key advantages compared to injections:

- Painless self-administration without needles or infusions

- Sustained release over hours or days from a reservoir or matrix

- Simple application and removal

- Enhancing patient compliance

Types of Peptides & Proteins Transdermal Patches We Can Develop

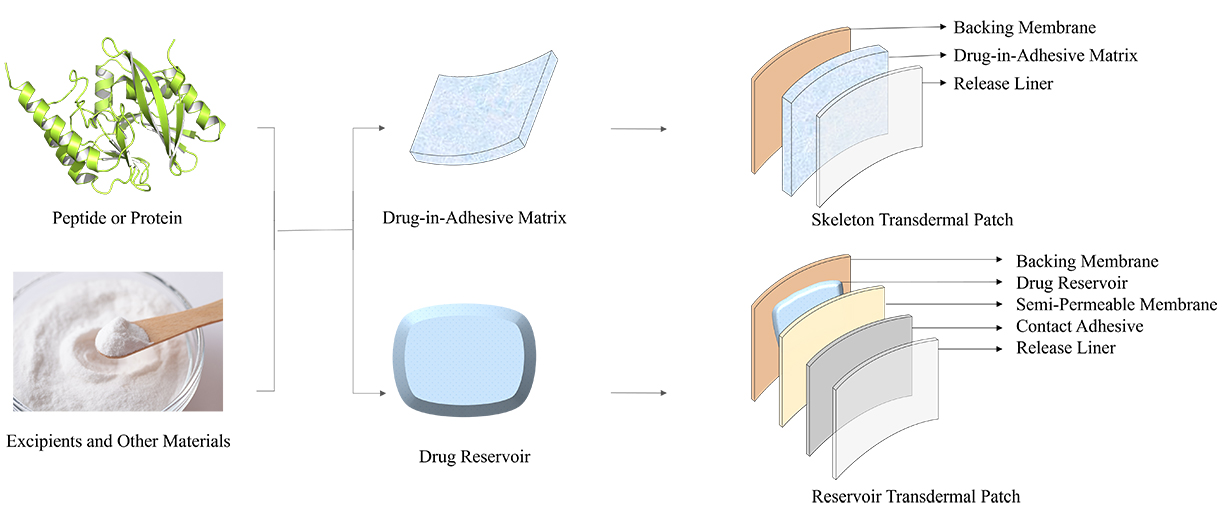

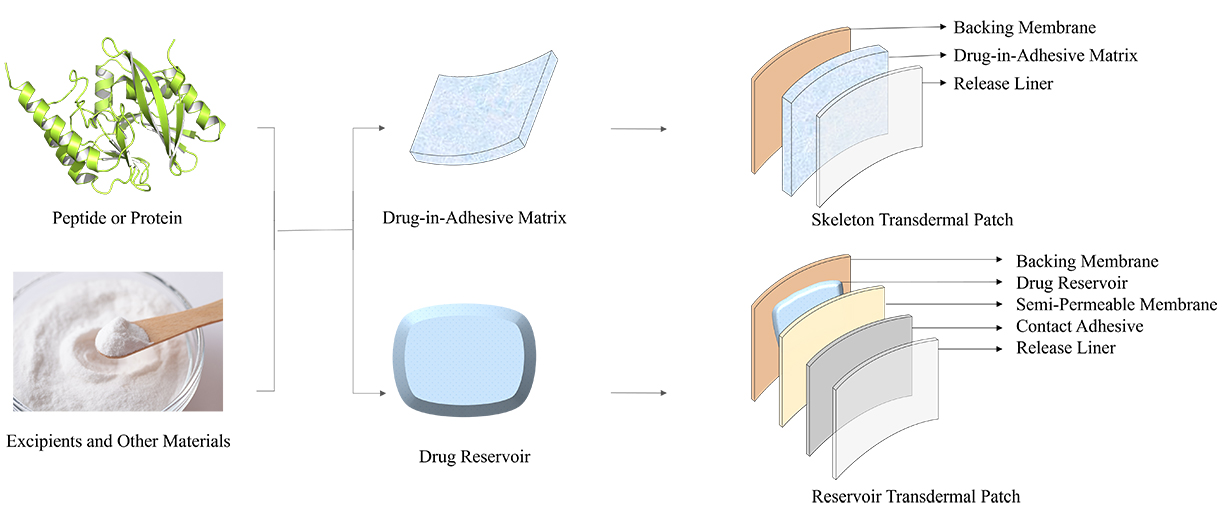

- Skeleton Transdermal Patch

Matrix-based patches are designed to deliver peptides and proteins directly through the skin. We select appropriate excipients and biocompatible polymer adhesive materials, and adopt advanced technology to combine raw materials and active ingredients into a drug-loaded matrix. This transdermal patch can be applied directly to the skin with a backing material. When used, the drug diffuses through the skin surface and enters the blood circulation continuously and stably.

- Reservoir Transdermal Patch

Reservoir patch is another patch type we specialize in developing, which offers advantages for sustained peptide and protein delivery. A key aspect is ensuring molecules remain stable within the reservoir depot over time. Through iterative formulation optimizations, we craft personalized solutions catering to each biologic's traits. This tailored design means dosing frequency can be conveniently lowered while therapeutic effects are prolonged. Partners gain transdermal convenience with reliable effectiveness.

How Do We Develop Peptides & Proteins Transdermal Patches?

| Types |

Skeleton Transdermal Patch |

Reservoir Transdermal Patch |

| Excipient selection |

According to the nature of the protein/peptide and customer needs, determine the required excipients, such as various adhesives, transdermal accelerators, solubilizers, and plasticizers. |

| Preparing solutions or dispersions |

The peptide/protein is dissolved or dispersed in a suitable solvent for its addition to the matrix/reservoir material. |

| Skeleton/Reservoir preparation |

The peptide/protein solution or dispersion is mixed with the matrix material to form the drug matrix. In this step we can use methods such as hot melting, solution casting or emulsion polymerization. |

We employ advanced techniques to design and fabricate depot patches with a reservoir layer. The reservoir is carefully engineered to hold the drug formulation, allowing for controlled and sustained release over an extended period. |

| Process research |

Mixed process factors: Equipment capacity, material addition sequence, mixing speed, time and temperature, degassing

Coating and drying process factors: Pump or screw speed, air flow rate, temperature and humidity |

| Other ingredients |

Other ingredients such as plasticizers and stabilizers, can be added as needed. |

| Patch quality assessment |

We focus on in vitro drug release, in vitro skin penetration, and adhesion of transdermal patches. |

Advantages of Our Peptides & Proteins Transdermal Patch Development Services

- Multidisciplinary experts in engineering, biologics, and clinical pharmacology optimize patch design.

- Patches are fully customized to your specific peptide, protein or vaccine for commercial success.

- Analytical excellence enables complete biologic characterization and stability studies.

- Seamless integration from early feasibility through pivotal trials and product launch.

- A collaborative, client-focused approach throughout each program stage.

At CD Formulation, our comprehensive services encompass the design, formulation, fabrication, and quality control of both skeleton-type and reservoir patches. We offer tailored solutions to meet specific therapeutic needs, ensuring optimal drug release and patient satisfaction. If you are interested in exploring the possibilities of peptide and protein transdermal patches,please contact us!

Related Services