Peptide & Protein Spray Dried Formulation Development

InquiryAt CD Formulation, developing optimal dosage forms is our specialty. As a leader in biologics, we're at the cutting edge of spray drying technologies. Through our expertise, we provide full-service solutions for engineering spray-dried peptides and proteins. Every aspect is optimized - from initial formulation through fine-tuning stability and bioavailability. Committed to quality and personalized services, our formulations cater to each molecule's distinctive traits.

What is Spray Drying?

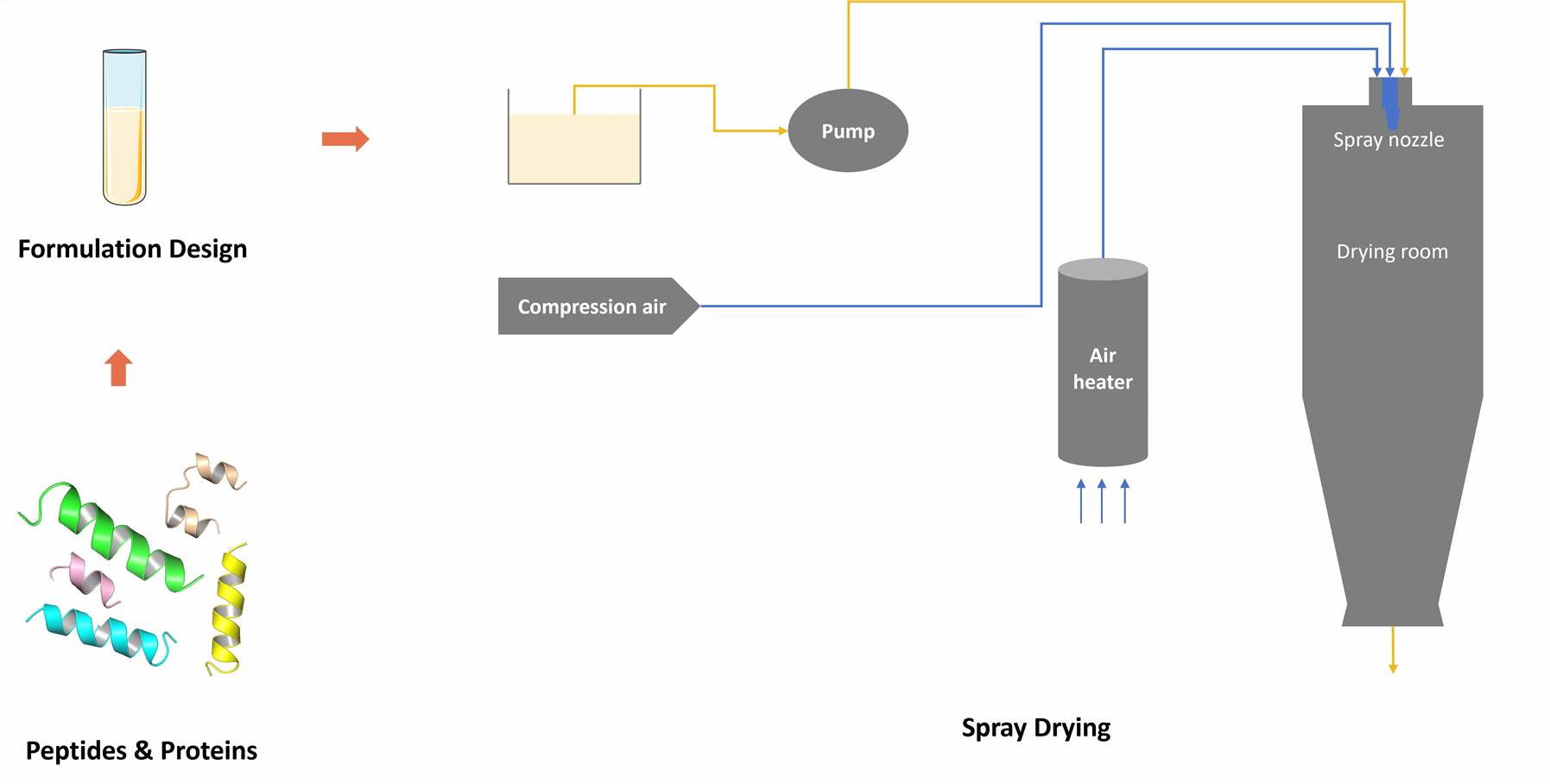

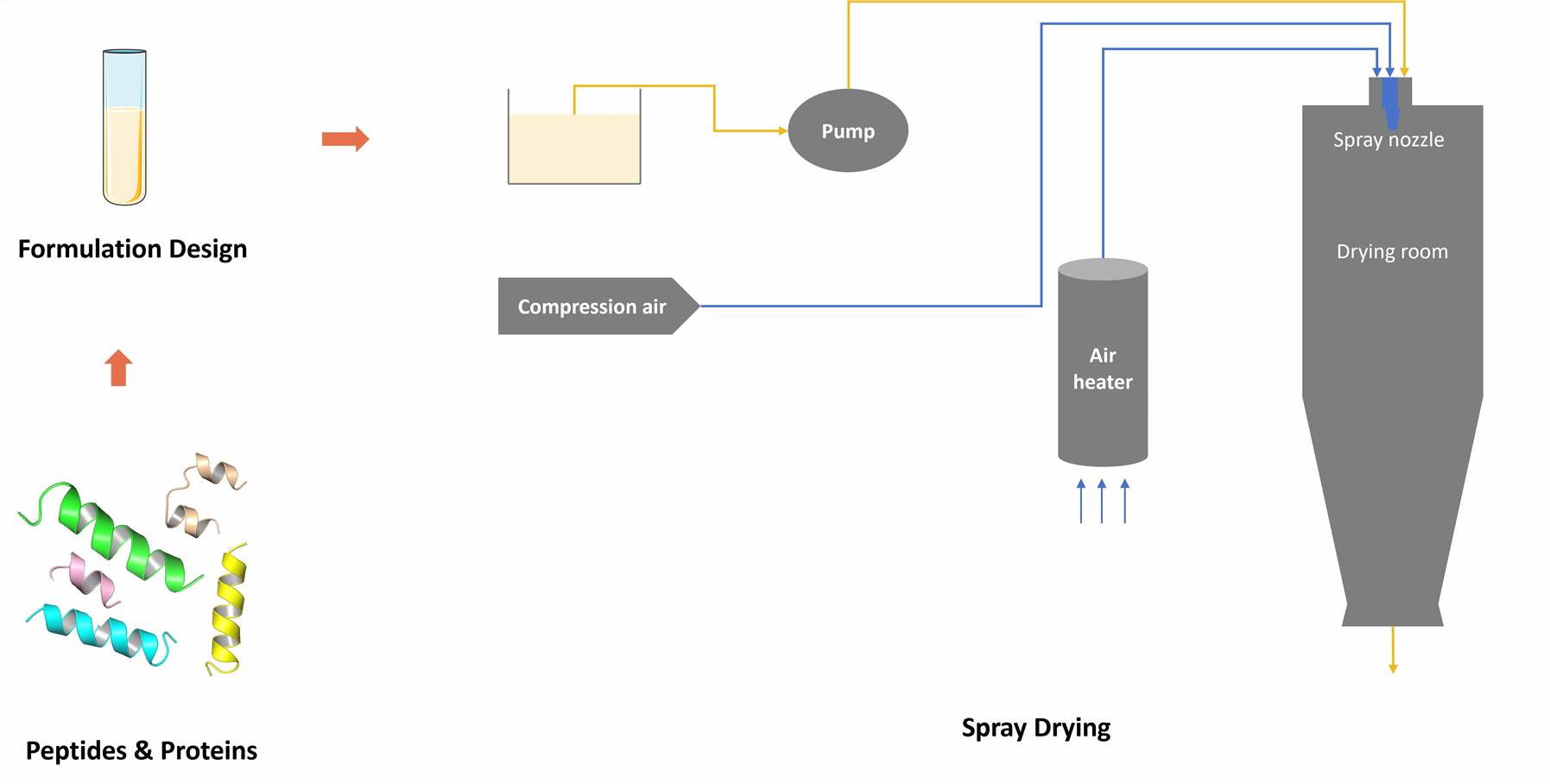

Spray drying is a widely used technique in the pharmaceutical, food, and chemical industries for converting liquid or semi-liquid substances into dry powder form. It involves the atomization of a liquid feed material into droplets, which are then rapidly dried by hot air or gas, resulting in the formation of fine particles or powder. Its ability to preserve heat-sensitive substances, produce fine particles, enhance solubility, enable encapsulation, and support continuous processing makes it a valuable tool in numerous industries.

Commonly Employed Excipients in Peptide and Protein Spray Drying

Stabilizers, such as sugars (e.g., trehalose, sucrose) and polyols (e.g., mannitol, sorbitol), are utilized to protect the structural integrity and biological activity of peptides and proteins during spray drying and subsequent storage.

Phospholipids and polysorbates are surfactants that prevent proteins from aggregating and adsorbing to surfaces, thereby maintaining the active molecules' stability.

Buffers are incorporated to maintain the desired pH range, ensuring protein stability and preventing degradation.

Our Peptide and Protein Spray-Dried Formulation Development Process

At CD Formulation, we follow a systematic and comprehensive approach to ensure the successful formulation of peptides and proteins.

We begin by evaluating the compatibility of the peptide or protein with the spray drying process and identifying potential challenges.

Our scientists will design a formulation strategy tailored to the specific molecule. Through an in-depth analysis of the active ingredient's properties, we craft a strategic design. Aspects like stability, solubility and targeted release kinetics guide material selection.

- Spray Drying Process Optimization

We utilize state-of-the-art spray drying equipment and techniques to optimize the process parameters. This includes adjusting variables such as inlet temperature, feed concentration, drying gas flow rate, and atomization parameters to achieve the desired particle size, morphology, and drug loading.

- Characterization and Stability Studies

We perform rigorous characterization and stability studies to assess critical quality attributes, including particle size distribution, moisture content, residual solvent levels, protein integrity, and bioactivity. These studies ensure the long-term stability and performance of the spray-dried formulation.

Highlights of Our Spray Drying Technology

- One highlight of our spray drying technology is its speed. Within just 5-40 seconds, the liquid starting material is fully transformed into powder.

- Droplet temperatures remain quite moderate, making it suitable for heat-sensitive materials. End products retain high quality.

- You can gain strong dispersion, fluidity and solubility attributes with our formulations.

- The particle size, density, moisture and other characteristics are tunable. Simply adjusting operating conditions provides precision control.

At CD Formulation, we are dedicated to pushing the boundaries of peptide and protein spray-dried dosage form development. With our expertise, state-of-the-art facilities, and focus on customized solutions, we offer comprehensive services to optimize the formulation, manufacturing, and characterization of spray-dried dosage forms for peptides and proteins. Contact us today to discuss your specific needs and explore how our services can benefit your product development journey!

Related Services