Peptide & Protein PLGA Microsphere Development

InquiryPLGA (Poly (lactic-co-glycolic acid)) microspheres represent a transformative platform for advancing biologics delivery. At CD Formulation, we combine materials science expertise, formulation design, and optimized processes to develop custom microspheres using PLGA polymers to improve the delivery of peptide, protein, and antibody drugs. We provide comprehensive services encompassing formulation design, development, optimization, and characterization of PLGA microspheres, ensuring the efficient delivery of bioactive molecules.

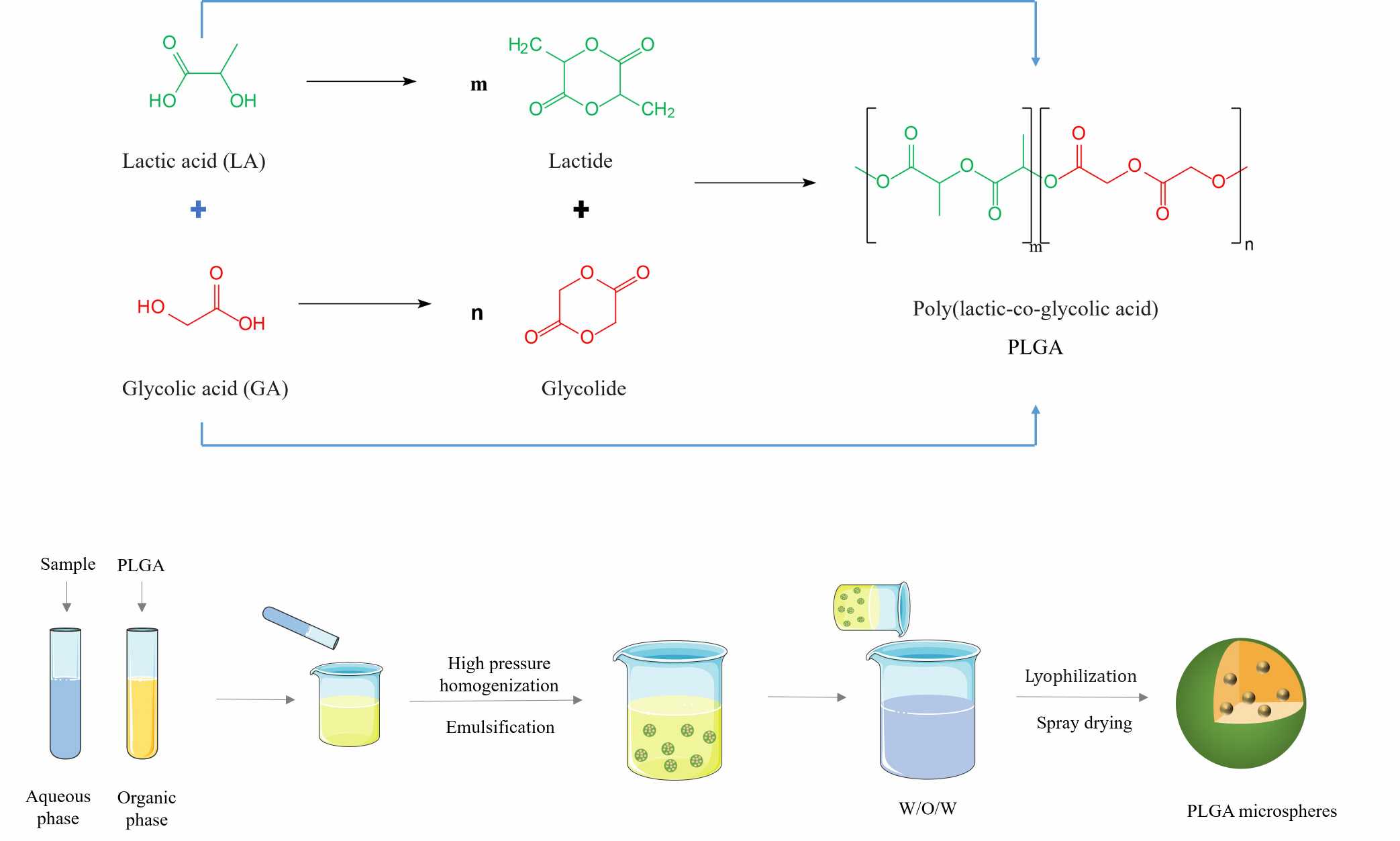

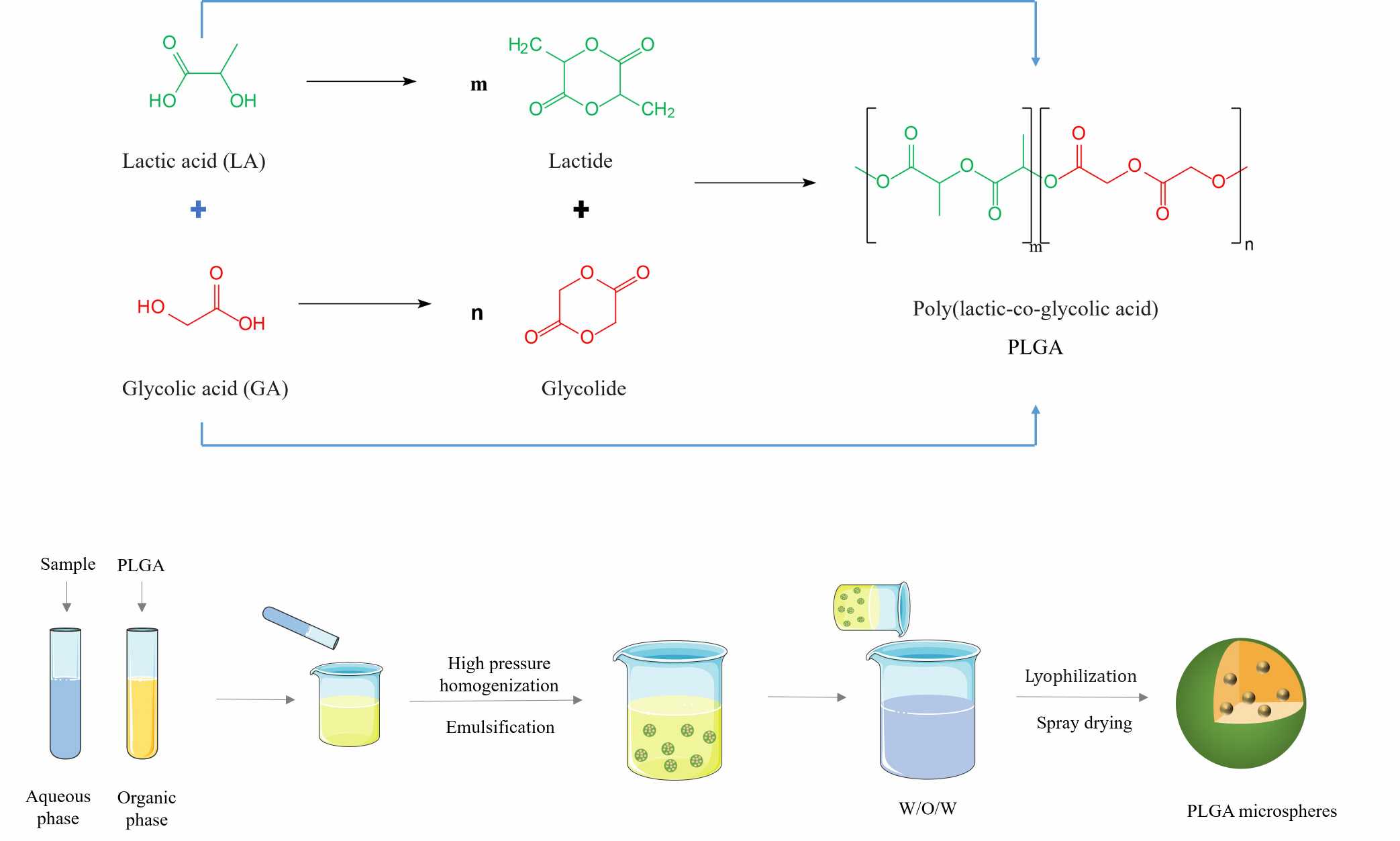

PLGA as Microsphere Material

PLGA, synthesized from lactic acid (LA) and glycolic acid (GA), is widely employed as a drug delivery carrier due to its biocompatibility and biodegradability. It can transport proteins, peptides, DNA, and various anticancer drugs. The properties of PLGA can be adjusted by modifying the monomer ratio, molecular weight, concentration, and terminal group, influencing factors such as encapsulation efficiency and drug release kinetics.

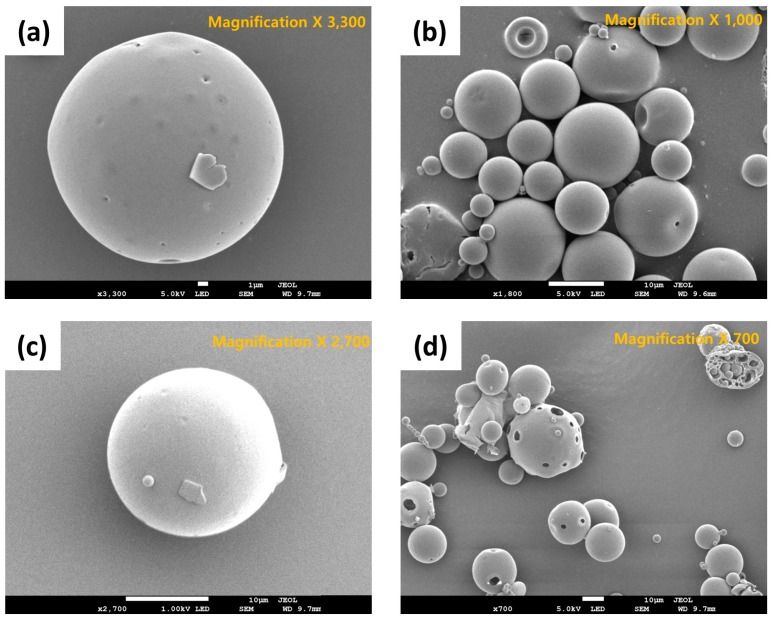

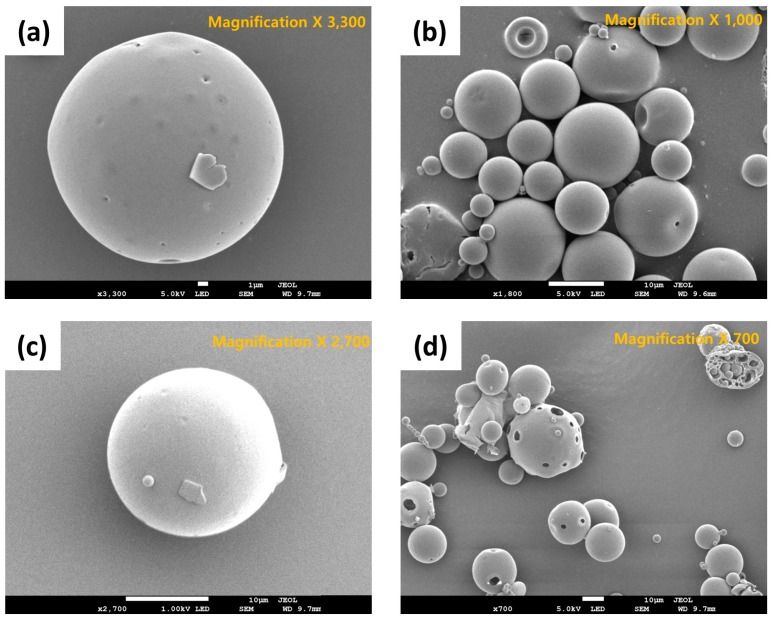

SEM images of peptide loaded PLGA microspheres (Park H.; et al. 2019)

SEM images of peptide loaded PLGA microspheres (Park H.; et al. 2019)

Our PLGA Microspheres Preparation Methods

Using PLGA as a carrier, we commonly use the emulsification-solvent evaporation method. The process involves a single or double emulsification method and can be applied to lipophilic or water-soluble drugs by controlling the properties of PLGA, solvent concentration and stirring rate. Our equipment capacities range from 200 ml to 20 L at laboratory scale and 50 L to 1500 L at pilot and production scale.

- High Pressure Homogenization

Using the principles of cavitation effect, collision effect and shear effect, the high-pressure homogenization method can achieve refinement and homogenization, and obtain ultra-fine microspheres and droplets, which can be used to prepare micron-sized nanoemulsions, particles, and lipids. We control particle size and distribution by adjusting parameters such as pressure and number of cycles. We use HomoLab high-pressure homogenizer provided by Italian FBF company, with a maximum pressure of 1800 bar, which is suitable for high-viscosity samples and various application needs.

After forming an emulsion formula that meets the requirements, we use a spray dryer to spray the liquid raw materials into the hot drying medium to convert them into dry powder. This process consists of atomization, drying and particle separation steps. It has the advantages of a high encapsulation rate, uniform particle size and is suitable for large-scale industrial production. We use Labplant's SD-06AG spray dryer, which has different nozzle sizes and real-time temperature monitoring to meet customer needs.

In microfluidic devices containing micron-scale channels, we flow the dispersed phase through one channel and the continuous phase through another channel. The two channels are perpendicular to each other, and droplets are formed at the junction of the channels. Microchannels can produce microspheres with sizes ranging from 10 to 300 μm. When expanding the production scale, only microreactor units need to be added in parallel, and all process control parameters are repeatable.

Electrospray technology is suitable for encapsulating sensitive materials such as proteins and cells. We inject a polymer solution into a nozzle and apply a voltage between the nozzle and the substrate to form droplets that are eventually atomized into particles. We can control the size of the resulting microspheres ranging from nanometers to micrometers.

Highlights of Our PLGA Microsphere Development Services for Peptide & Protein Delivery

- Tunable degradation kinetics

- Zero-order controlled release

- High encapsulation efficiency

- Protection from degradation

- Targeted delivery capabilities

- Defined particle manufacturing

- Robust characterization analytics

- Expert formulation development team

CD Formulation provides cutting-edge PLGA microsphere development services and offers clients dedicated, end-to-end expertise throughout the product lifecycle. Whether sustained release kinetics, targeted biodistribution or stabilization against degradation are needed, our formulation scientists customize versatile particulate systems for each biologic's unique profile. Contact us today to embark on a journey towards innovative drug delivery solutions!

References

- Park H.; et al. Effect of stabilizers on encapsulation efficiency and release behavior of exenatide-loaded PLGA microsphere prepared by the W/O/W solvent evaporation method. Pharmaceutics. 2019, 11(12):627.

- Su Y.; et al. PLGA-based biodegradable microspheres in drug delivery: recent advances in research and application. Drug Deliv. 2021, 28(1):1397-1418.

Related Services

SEM images of peptide loaded PLGA microspheres (Park H.; et al. 2019)

SEM images of peptide loaded PLGA microspheres (Park H.; et al. 2019)