Peptide & Protein PLA Microsphere Development

InquiryAt CD Formulation, our team comprises highly skilled scientists with extensive experience in the development and characterization of polylactic acid (PLA) microspheres for peptide and protein delivery. We leverage our expertise to provide tailored PLA microsphere development services that meet the unique requirements of each client and their specific drug candidates.

Why Choose PLA Microspheres to Deliver Peptide and Protein?

Protein and peptide drugs are highly effective at eliciting therapeutic activity due to their specific interactions with biological targets. However, their administration often requires repeated doses due to their short half-lives and rapid clearance from circulation. Polymer microspheres offer a promising solution by encapsulating proteins and peptides. Long-acting injectable (LAI) microspheres, particularly those based on biodegradable polymers like PLA, have gained attention for their high drug loading, prolonged release, and improved patient compliance.

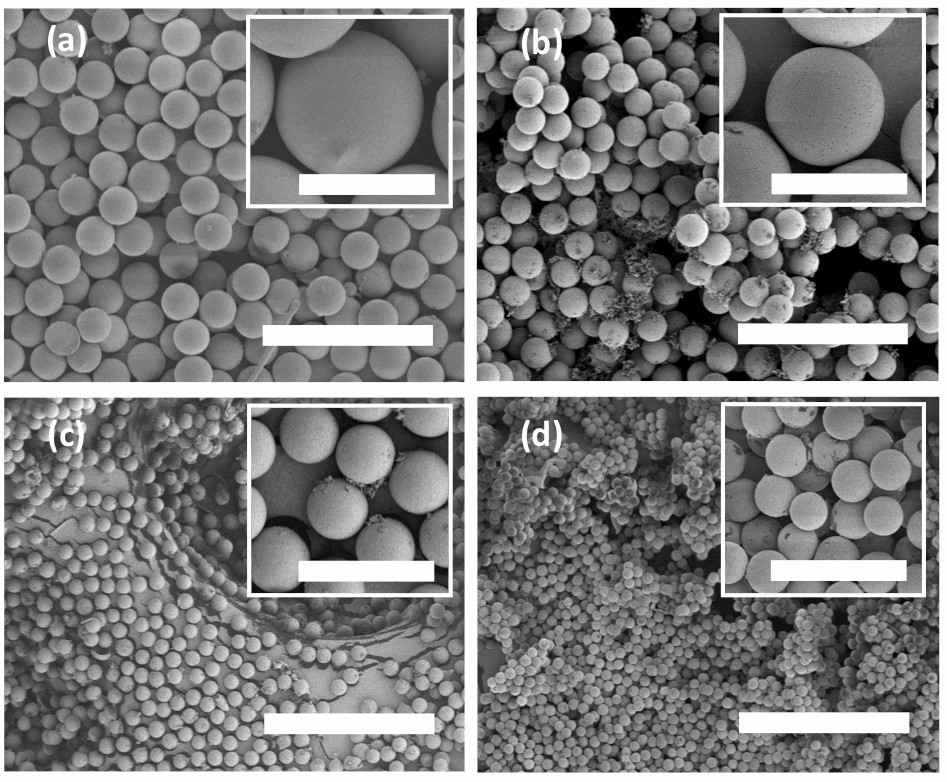

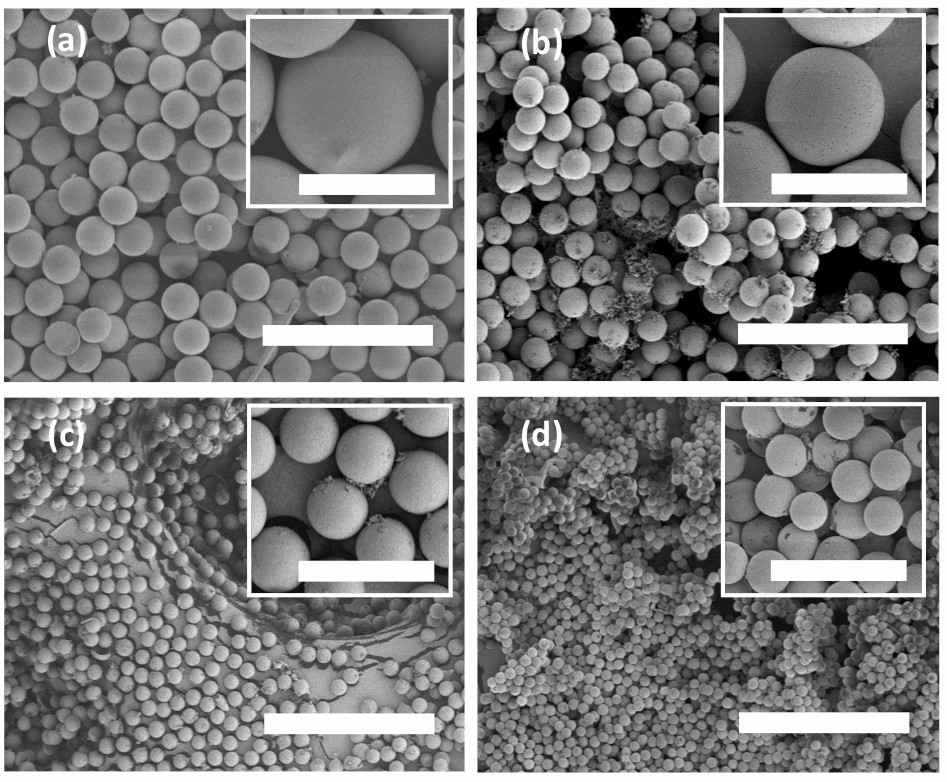

SEM images of PLA microspheres (Watanabe T.; et al. 2011)

SEM images of PLA microspheres (Watanabe T.; et al. 2011)

How Do We Develop PLA Microspheres for Peptide & Protein Delivery?

Our team works closely with clients to understand their specific goals and requirements, ensuring a customized approach throughout the development journey. Key steps in our development process include:

We carefully select the appropriate PLA polymer and optimize its composition to achieve desired release kinetics and stability. Formulation parameters, such as drug loading, polymer concentration, and excipient selection, are tailored to achieve optimal encapsulation efficiency and controlled release.

At CD Formulation, we leverage decades of expertise across multiple microencapsulation platforms to fabricate optimized PLA microspheres. Techniques such as emulsion-solvent evaporation, spray drying, microfluidics, and precision particle fabrication equip us to tightly control critical parameters based on the drug payload. State-of-the-art facilities and equipment ensure reproducible fabrication and scale-up processes to smoothly transition PLA microspheres from lab to market.

In order to better optimize the formula and process, we will conduct an in-depth analysis of the characteristics of PLA microspheres. By exploring release kinetics, polymer degradation rates, and peptide/protein stability under various temperature, pH, and enzymatic conditions that reflect physiological environments, we will gain a deeper understanding of the complex properties and behavior of microspheres. This rigorous characterization serves as a guiding guide, allowing us to refine and optimize our formulations, ensuring their efficacy, safety, and suitability for the intended therapeutic application.

Our Technology Platforms for PLA Microsphere Characterization

| Technologies |

Applications |

| Size exclusion chromatography |

Measure the molecular weight of PLA microspheres at different time points to evaluate the encapsulation efficiency and degradation behavior during in vitro release. |

| Scanning electron microscope (SEM) |

Examine the size, surface structure, and shape of microspheres. |

| Laser diffraction |

Determine the particle size and size distribution of microspheres. |

| Mercury porosimeter |

Determine the total invaded volume, total pore area, and porosity. |

| Differential Scanning Calorimeter (DSC) |

Characterize the solid state of polymers. |

| HPLC |

Characterize and quantify proteins/peptides and their chemical degradation. |

| SDS-PAGE |

Identify molecular weight changes of proteins/peptides after encapsulation and measure the aggregation or structural integrity of proteins/peptides to some extent. |

| Fourier transform infrared |

Test the secondary structure integrity of peptides/proteins and Determine interactions between polymers and encapsulated drugs. |

| Gas chromatography |

Evaluate residual solvent content. |

| USP apparatus IV |

Conduct an in vitro release test of the microspheres. |

Advantages of Our Peptide & Protein PLA Microsphere Development Services

- PLA microspheres can be degraded by microorganisms into harmless substances (lactic acid) in the body.

- By controlling parameters such as the molecular weight, concentration, and preparation process of polylactic acid, we can regulate the size and distribution of PLA microspheres.

- We can introduce functional groups such as hydroxyl and carboxyl groups on the surface of PLA microspheres to change their properties and functions.

- The PLA microspheres we developed can be widely used in tissue engineering, regenerative medicine, drug delivery and other fields.

CD Formulation provides full-service expertise throughout the product lifecycle. If you are seeking a reliable partner for the development of PLA microspheres, please contact us to discuss how custom formulations can maximize the therapeutic potential of your peptide or protein candidates.

References

- Watanabe T.; et al. Continuous fabrication of monodisperse polylactide microspheres by droplet-to-particle technology using microfluidic emulsification and emulsion–solvent diffusion. Soft Matter, 2011, 7(21): 9894-9897.

- Butreddy A.; et al. PLGA/PLA-Based long-acting injectable depot microspheres in clinical use: production and characterization overview for protein/peptide delivery. Int J Mol Sci. 2021, 22(16):8884.

Related Services

SEM images of PLA microspheres (Watanabe T.; et al. 2011)

SEM images of PLA microspheres (Watanabe T.; et al. 2011)