Peptide & Protein Microsphere Development

InquiryAt CD Formulation, we leverage decades of expertise in microencapsulation technology to develop customized PLGA and other polymer microspheres for improved delivery of peptide, protein, and antibody therapies. Our experienced scientists can engineer microspheres with tailored release kinetics, functionalized surfaces, and excellent drug loading to overcome the barriers of biologic drug delivery.

Types of Microspheres We Can Develop

Drugs are continuously dissolved and diffused into the external environment through pores in porous microspheres so that they can exert their medicinal effects. In order to control the release of drug, we adjust the formula and process to change the number of holes in the spheres. This reduces the surface area and drug loading capacity of the microspheres.

- Double Layer Microspheres

There is a core-shell structure to double-layer microspheres. Our microspheres feature an outer shell made of degradable polymer material coated with drugs as well as a biodegradable polymer material for the core. When compared to microspheres with pores, double-layer microspheres release mainly based on their core-shell structure. It is because of their high sealing and encapsulation rates that double-layer microspheres are able to carry a large amount of drug and have high loading capacities.

Magnetic microspheres are modified based on the first two microspheres. At CD Formulation, we make ultra-fine powders from magnetic metals or metal oxides and disperse them in polymer materials or drugs to produce magnetic microspheres, which can move to targeted organs or tissues under the influence of an external magnetic field.

Our Materials for Peptide & Protein Microsphere Development

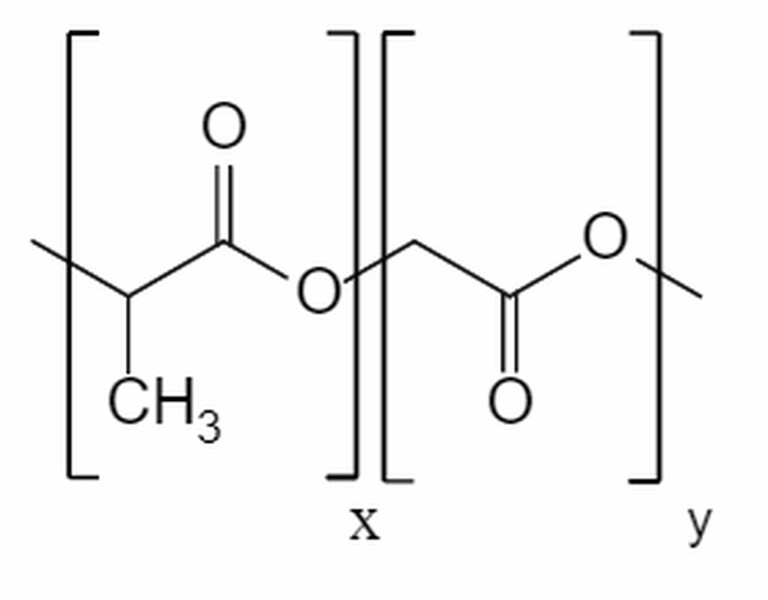

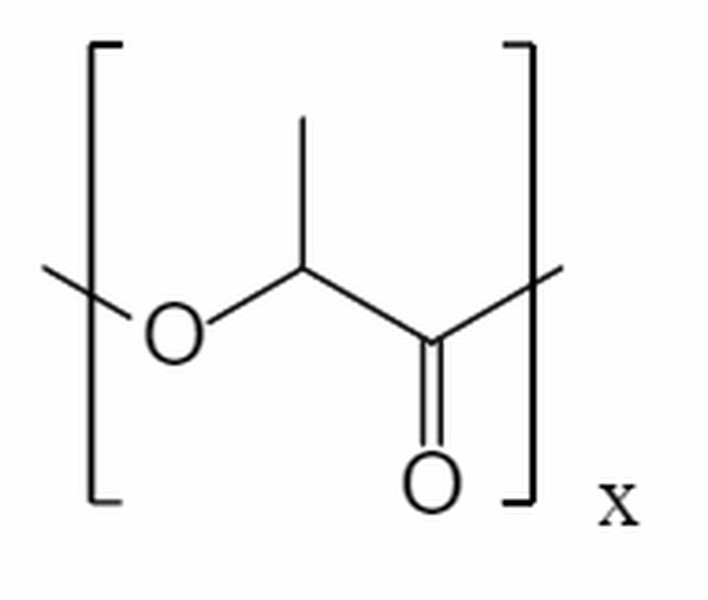

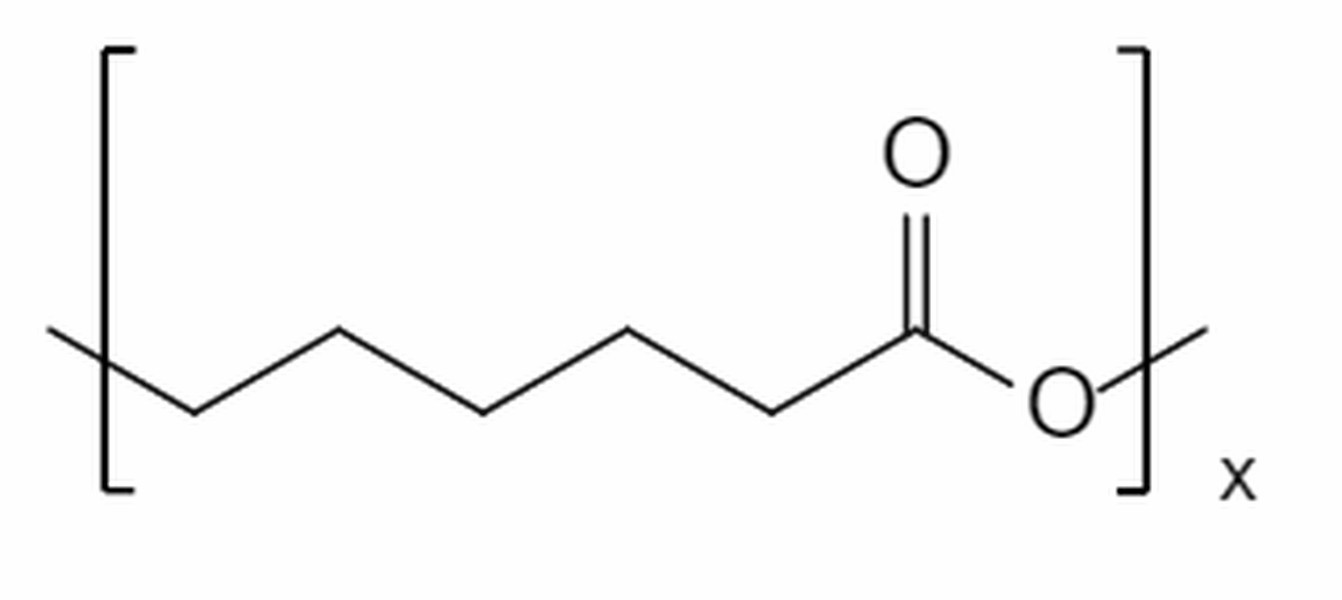

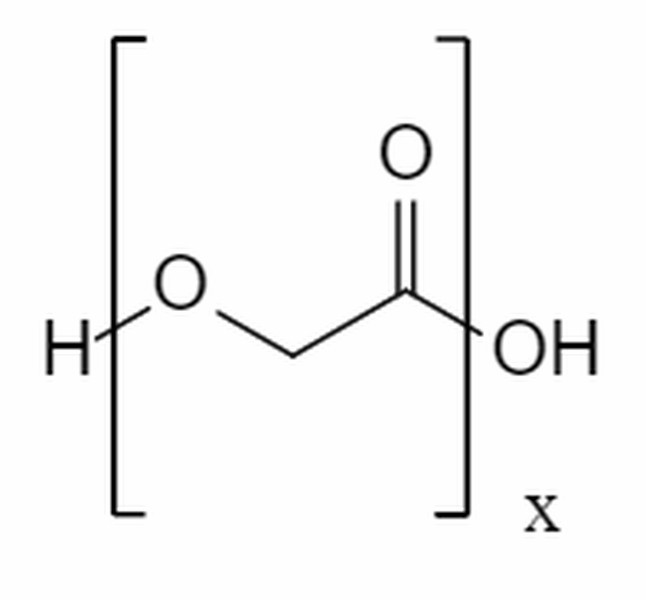

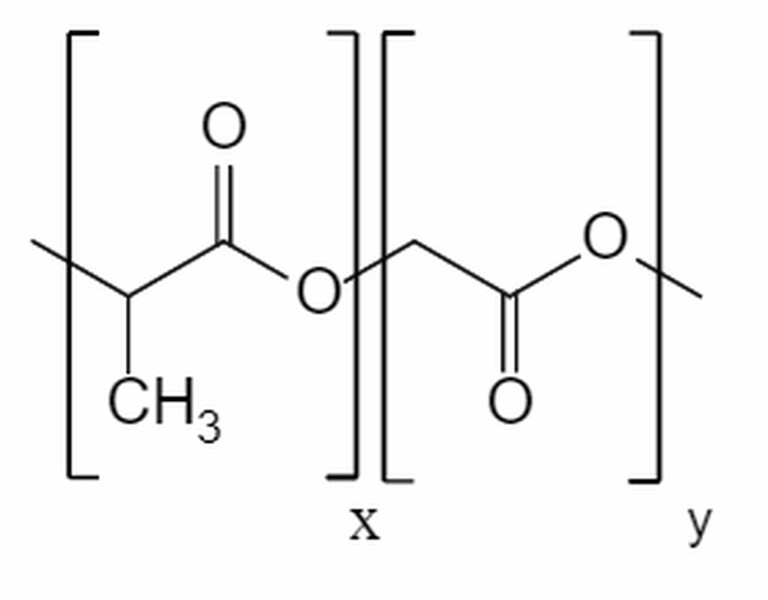

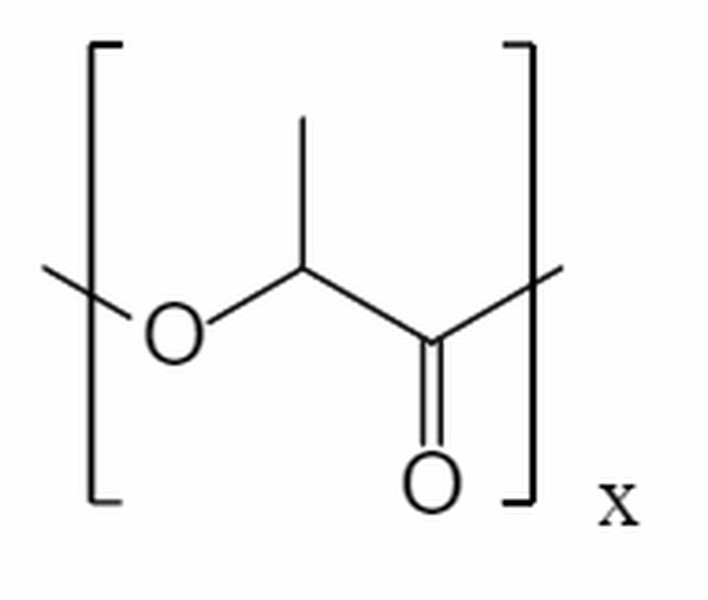

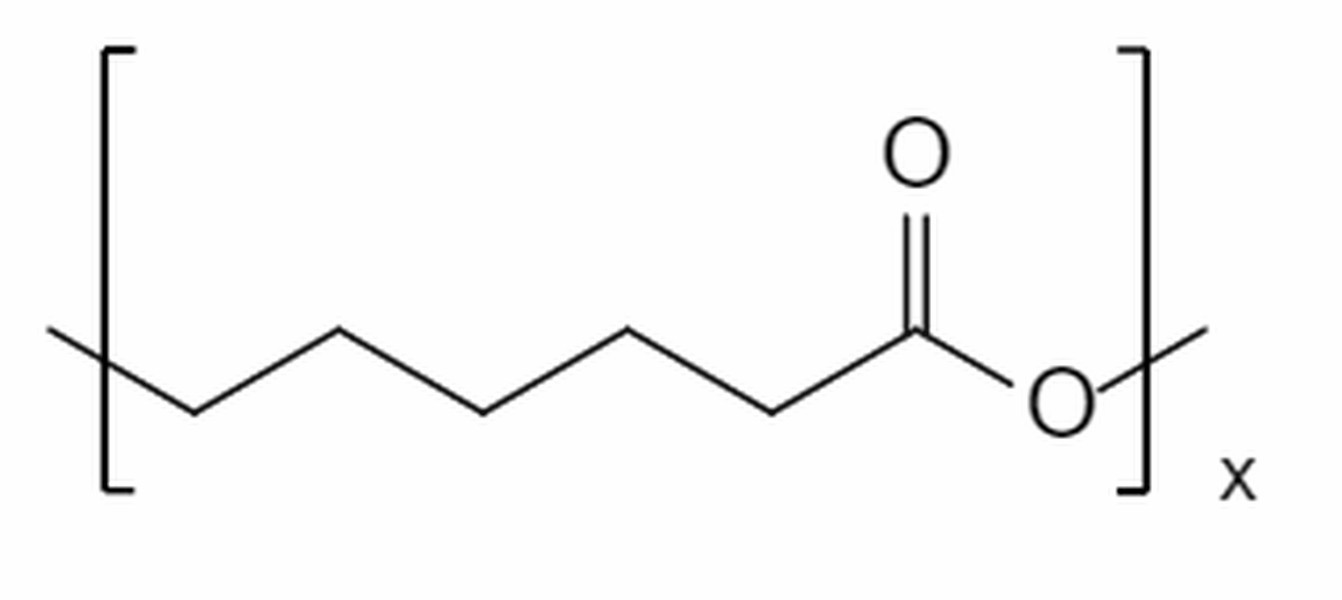

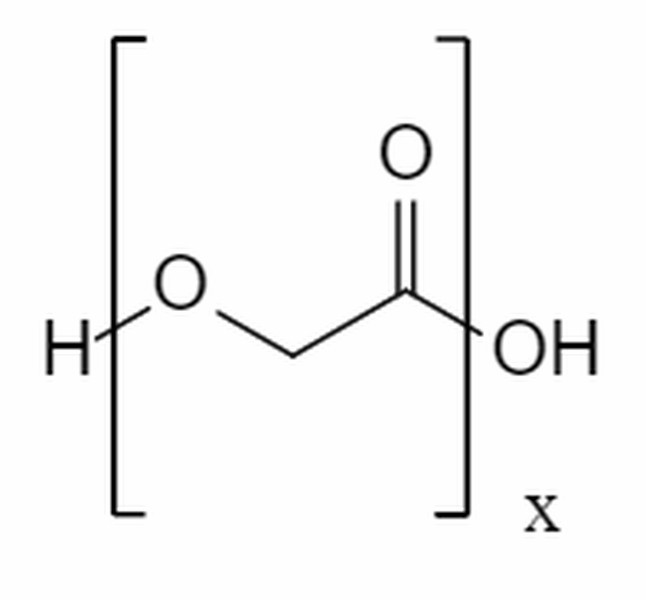

| Structures |

|

|

|

|

| Types |

Poly (lactic-co-glycolic acid), PLGA |

Polylactic acid, PLA |

Poly(ε-caprolactone), PCL |

Polyglycolide, PGA |

Our Peptide & Protein Microsphere Development Process

-

Polymer Selection

We carefully choose biodegradable polymers that meet the specific requirements of the project, considering factors such as biocompatibility, degradation kinetics, and encapsulation efficiency.

-

Formulation Optimization

Our experts leverage their extensive knowledge of polymer science and drug delivery to optimize the formulation parameters, including polymer concentration, solvent selection, and emulsification techniques, to achieve the desired encapsulation efficiency and release kinetics.

-

Microsphere Encapsulation

Using advanced techniques, we precisely encapsulate the peptides and proteins within the microspheres, ensuring their stability and protection during storage and delivery.

-

Separation and Solidification

After separating the microspheres from the system, we can effectively control the residual amounts of organic solvents and toxic substances by optimizing the curing method, temperature, time, and cleaning methods.

-

Quality Control

This includes comprehensive analytical characterization of size, morphology, charge, drug loading and release kinetics.

Advantages of Our Peptide & Protein Microsphere Development Services

- Long-term effect: The sustained-release effect of peptide & protein microspheres can be achieved by reducing the frequency of administration.

- High efficiency: Microspheres can be administered by injection, bypassing the first-pass effect.

- Safety: By transporting microspheres to specific sites, off-target effects can be reduced.

- Professionalism: We can help customers solve the most basic problems of encapsulation rate and particle size uniformity in the development process of microspheres, as well as issues such as sterility assurance and process amplification in the production process.

- Potential: Microspheres have a large space for development in peptide and protein drugs and have great market potential.

CD Formulation specializes in designing and optimizing biodegradable microspheres tailored to encapsulating and delivering peptides and proteins. If you're seeking innovative solutions for targeted and efficient drug delivery, contact us today!

Related Services