CD Formulation can provide one-stop services for impurity determination including process-related impurity analysis and product-related impurity analysis services for bio-pharmaceuticals.

Why to Perform Impurity Determination?

Impurities in bio-pharmaceuticals are generally divided into product-related impurities and process-related impurities. Product-related impurities include aggregates, degradation products, charge isomers, hydrophobic variants, inactive virus particles, non-intended polysaccharides, incompletely packaged virus-like particles, etc. Process-related impurities include cell matrices (host cell proteins, host cell DNA), cell culture (inducers, antibiotics, or media components) or downstream process residues. These impurities will not only affect the efficacy of biological drugs, but may also pose safety risks. Therefore, strict quality control is required in the drug development and production processes.

Our Services for Impurity Determination

CD Formulation will develop personalized proposals to perform impurity determination for bio-pharmaceuticals based on the customer's needs. Based on advanced precision instrument testing platform, CD Formulation provides a series of impurity determination services for global researchers, including but not limited to:

- Process-Related Impurity Analysis

Process-related impurities refer to impurities produced during the production process, including impurities produced in cell matrices, cell culturesor downstream processes, etc.

Including host cell protein(HCP), host cell DNA, protein A residue.

Including inducers, antibiotics, serum, other culture medium components.

- Downstream process residue

Including enzymes, chemical and biochemical treatment reagents (such as cyanogen bromide, guanidine, redox agents), inorganic salts (such as heavy metals, arsenic, non-metal ions), solvents, carriers, ligands (such as monoclonal antibodies) and other precipitates.

- Product-Related Impurity Analysis

Product-related impurities (e.g., precursors, certain degradation products) are molecular variants produced during production and/or storage that are not comparable in activity, effectiveness, and safety to the intended product.

- For biotech products, product-related impurities include aggregates, degradation products, charge isomers, hydrophobic variants, etc.

- For various types of vaccines, product-related impurities include inactive virus particles, non-intended polysaccharides, incompletely packaged virus-like particles, etc.

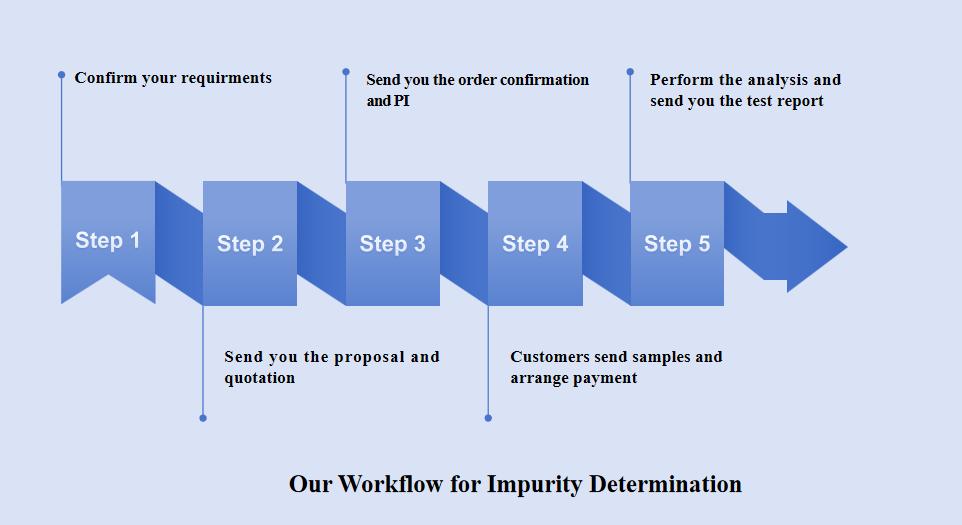

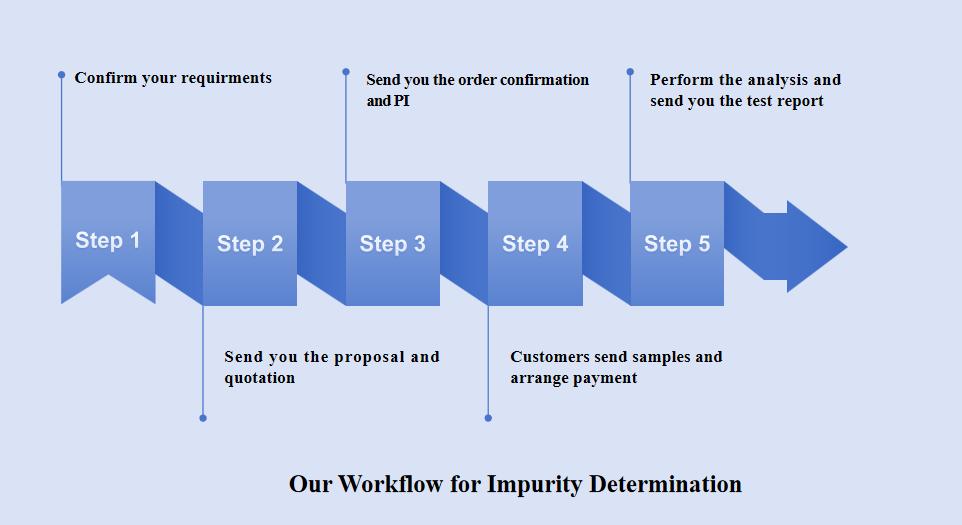

Our Workflow for Impurity Determination

Here are following five steps to easily solve your requirements.

Advantages of Our Services

- Have multi-comprehensive and systematic analysis platform.

- To provide you with the professional proposal.

- Arrange the most efficient testing services for your project.

- Excellent after-sales service.

How to Contact Us?

If you have a requirement about our services, please contact us by phone or email, our colleagues will reply to you within three working days.

Related Services