Hydrogel Development for Nucleic Acid Delivery

InquiryAs a company specializing in advanced biomedical solutions, CD Formulation places a strong emphasis on innovation and research. Our expertise lies in designing and developing hydrogels with tailored properties optimized for applications and payloads. Through material selection, synthesis, and characterization capabilities, our formulation scientists engineer hydrogels to facilitate precise and sustained release of nucleic acids at desired sites.

What is Hydrogel?

Hydrogels are three-dimensional polymer networks that can absorb large amounts of water or biological fluids. They resemble natural tissues due to their high-water content and soft gel-like consistency. By entrapping therapeutic molecules within their cross-linked matrices, hydrogels can provide controlled release of payloads over extended periods. This makes them well-suited to various biomedical applications including drug delivery and tissue engineering.

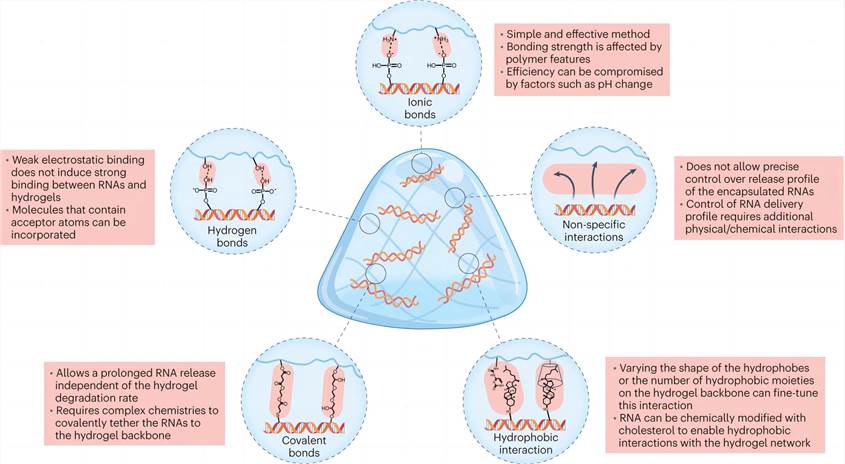

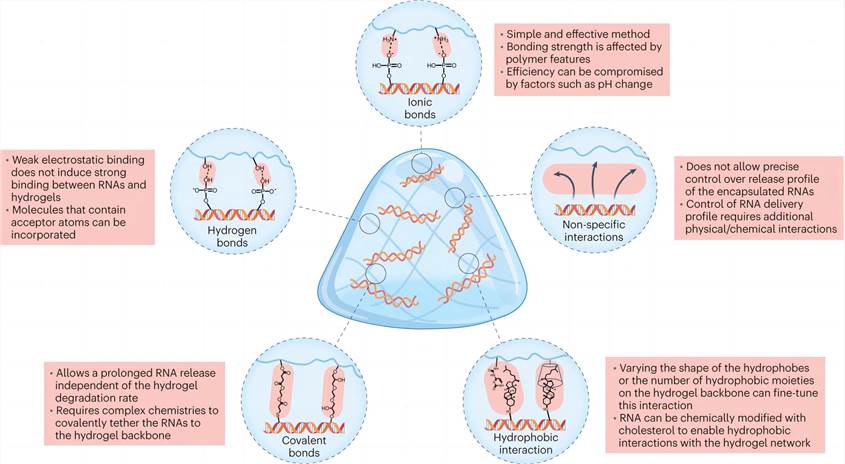

Types of interactions between nucleic acids and hydrogel networks (Zhong R.; et al., 2023)

Types of interactions between nucleic acids and hydrogel networks (Zhong R.; et al., 2023)

What Can We Do for Hydrogel Development?

- Sustained Release Hydrogel Development

Custom polymer synthesis allows control of degradation rates via hydrolytic or enzymatic pathways.

Tuning of crosslink density, porosity, and water content to precisely modulate release kinetics.

In vitro/in vivo correlation studies to optimize multiple-week payload exposure profiles.

- Stimuli-Responsive Hydrogel Development

Engineering of temperature-, pH-, or ion-sensitive moieties directly within polymer backbones.

Incorporation of disease-relevant enzyme-cleavable substrates or affinity domains.

Multi-factorial designs combine degradation and trigger release mechanisms.

- Tailored Release Characteristics

Comprehensive rheological, swelling and degradation assessments.

Real-time and endpoint analytical methods (PLC, spectroscopy) for profile release.

Cell-based assays and 3D bio-printing to simulate tissue-level release.

- Targeted Delivery Platforms

Conjugation or encapsulation of cell-specific antibodies, peptides or small molecules.

Evaluation of targeting efficiency and hydrogel biodistribution.

Development of targeted spheres, discs or other device-compatible formats.

- Preclinical Efficacy Studies

Assessment of hydrogel biocompatibility, local and systemic toxicity.

Quantitative/qualitative in vivo analysis of transgene expression profiles.

Studies in disease models (cancer, inflammation, musculoskeletal) to demonstrate therapeutic effects.

Materials We Use for Hydrogel Preparation

|

Natural Polymers |

Collagen, fibrin, alginate, chitosan, hyaluronic acid |

| Synthetic Polymers |

PEG, PVA, PEG-co-PVA, PEG acrylates |

| Peptides |

RGD, IKVAV, integrin-binding peptides |

| Block Co-polymers |

PCL-PEG, PLA-PEG |

| Dendrimers |

PAMAM, PPI |

| Modified Polysaccharides |

Methacrylated hyaluronic acid, chitosan |

| Crosslinking Agents |

Glutaraldehyde, genipin, carbodiimides, photoinitiators |

Our Platforms for Hydrogel Development

|

Physical Crosslinking |

- Hydrogel polymer networks can be quickly created using hydrogen bonds or hydrophobic interactions. The physical cross-linking techniques we specialize in include temperature-induced gelation, pH-induced gelation or solvent-induced gelation.

|

| Chemical Crosslinking |

- Chemical cross-linking involves the use of cross-linking agents or reactions to form covalent bonds between polymer chains, resulting in a relatively stable hydrogel network. Our commonly used cross-linking agents include glutaraldehyde, genipin or photoinitiators.

|

| Enzyme Crosslinking |

- We can use enzymes to catalyze cross-linking reactions between specific functional groups on the hydrogel polymer. Enzymatic cross-linking has the advantages of mild reaction conditions, high selectivity, and biocompatibility.

|

| Self-Assembly |

- Taking advantage of the inherent properties of certain polymers or peptides, we can prepare drug-loaded hydrogels by adjusting parameters such as concentration, temperature, or pH to trigger self-assembly and gelation.

|

| Electrostatic Interaction |

- By choosing oppositely charged polymer materials and cargo, we can prepare hydrogels based on electrostatic interactions.

|

| Mixed Methods |

- Depending on the customer's needs, we can combine different methods, such as physical and chemical cross-linking or covalent cross-linking and self-assembly, to obtain hydrogels with enhanced properties and functionality.

|

Why Choose Our Hydrogel Development Services?

- Our core technologies like microfluidics, 3D printing, and high-throughput screening accelerate development.

- We possess expertise in responsive biomaterials that enhance therapeutic delivery and regenerative functions.

- We employ comprehensive characterization techniques to evaluate the properties of the hydrogels, including mechanical strength, swelling behavior, degradation rate, and release kinetics.

- Our hydrogel development services cater to a wide range of applications, including drug delivery, tissue engineering, wound healing, and biosensors.

CD Formulation can customize hydrogel properties such as mechanical strength, porosity, degradation rate, and biocompatibility to ensure optimal performance. Contact us and let us help accelerate your hydrogel development process!

References

- Zhong R.; et al. Hydrogels for RNA delivery. Nat Mater. 2023, 22(7):818-831.

- Fliervoet L.A.L.; et al. Polymers and hydrogels for local nucleic acid delivery. J Mater Chem B. 2018, 6(36):5651-5670.

Related Services

Types of interactions between nucleic acids and hydrogel networks (Zhong R.; et al., 2023)

Types of interactions between nucleic acids and hydrogel networks (Zhong R.; et al., 2023)