Computer-Aided Peptide & Protein Formulation Development

InquiryAt CD Formulation, our computer-aided formulation development services offer comprehensive solutions for optimizing the delivery of peptides and proteins. With our expertise in molecular modeling, simulations, and data-driven approaches, we enable efficient design, analysis, and optimization of formulations, reducing the time and resources required for experimental trials and accelerating biologic products launch.

What is Computer-Aided Formulation Development?

Computer tools are increasingly used to speed up the development of drug formulations. Using advanced algorithms, modeling and simulation methods, computers can help predict and analyze the behavior, interactions, and performance characteristics of ingredients in a formulation. By inputting parameters such as therapeutic properties, desired drug properties, and material properties, formulation scientists can quickly screen different polymer excipient combinations and structures in silico. This allows formulation properties such as drug solubility, stability, release kinetics and toxicity to be accurately predicted and optimized prior to laboratory synthesis.

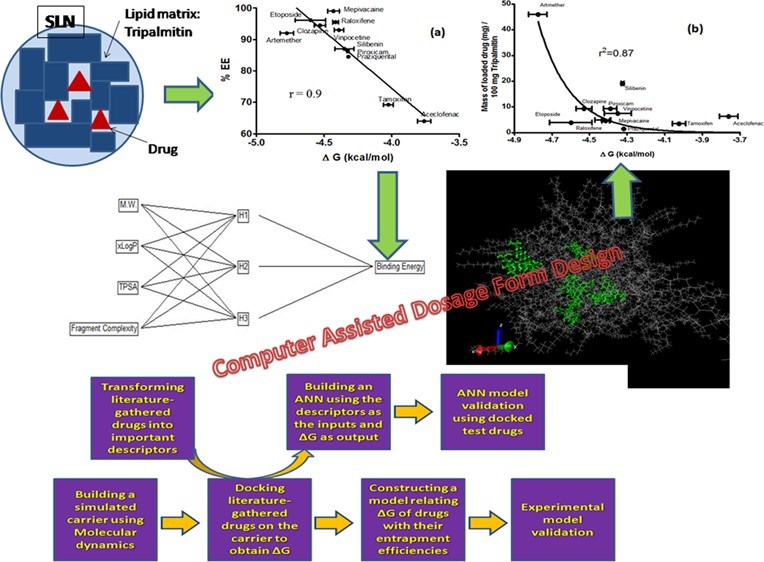

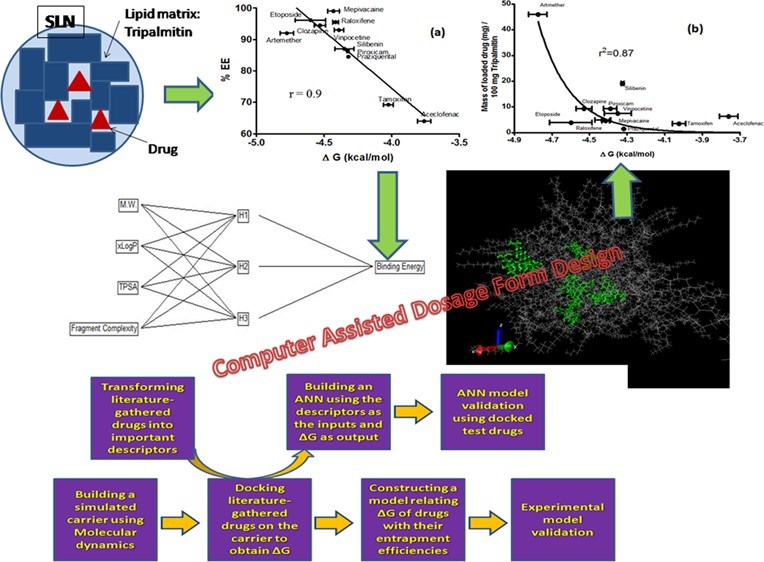

Computer-assisted drug formulation design process (Metwally A.A.; et al. 2015)

Computer-assisted drug formulation design process (Metwally A.A.; et al. 2015)

How Do We Proceed with Computer-Aided Peptide & Protein Formulation Development?

| Molecular Dynamics Simulations |

Study protein-excipient interactions at the atomic level to design formulations that maintain stability and structure. |

| Coarse-Grained Modeling |

Simulate the self-assembly of delivery systems like nanoparticles, micelles, and nanostructured hydrogels.

Predict size, morphology, and encapsulation efficiency. |

| In Silico Screening |

Databases of excipients coupled with machine learning algorithms rapidly screen and score formulations based on predefined optimization objectives. |

| Kinetic Modeling |

Computational flux models of release mechanisms aid formulation of targeted PK/PD profiles for wound healing, immunotherapy, etc. |

| Toxicity Prediction |

Machine learning identifies toxicological liabilities early to guide selection of the safest, most effective excipients and routes of administration. |

| Process Modeling |

Digital twins of manufacturing processes help design, optimize and scale-up production to ensure quality and reproducibility. |

Applications of Our Computer-Aided Formulation Development Services

Our predictive modeling platforms incorporate genetic, clinical and lifestyle data to design customized dosage forms tailored to individuals. Simulation rapidly identifies optimal combinations of drug, dose, excipients and release profiles for maximum efficacy and safety based on a patient's biomarkers and disease state.

Molecular dynamics simulations provide atomic level insights into protein-carrier interactions. We predict stabilizing excipients and formulations to maintain the higher order structure of peptides and other fragile molecules. Computational fluid dynamics examines the dispersion and encapsulation efficiency of various particulate systems. This enables the development of tailored and effective delivery systems for challenging biologic drugs.

Physiologically based pharmacokinetic modeling incorporates anatomical and physiological variables to simulate 'what-if' scenarios. This aids formulation of products with predetermined absorption and elimination profiles. For example, simulations of an antibiotic's plasma concentration versus time curve help match profiles to specific dosing schedules and disease states.

Our digital manufacturing systems recreate production processes at virtual scale. They integrate data on equipment, materials handling, and facility design to model throughput. AI then identifies bottlenecks and optimization opportunities, minimizing the need for expensive physical experimentation and facilitating scale-up for clinical and commercial needs.

Highlights of Our Computer-Aided Formulation Development Services

- Leverage cutting-edge AI algorithms and machine learning techniques to analyze vast amounts of data and generate valuable insights for formulation design.

- Integrated lab and computational approaches reduce design-build-test cycles.

- Accelerate the identification of optimal drug formulations and streamline the development process.

- Ensure precise dosing, controlled release, and enhanced patient compliance.

Leveraging the latest computational tools, CD Formulation provides a fully integrated approach to designing optimal formulations for challenging biologic molecules. By combining predictive molecular modeling with lab experimentation, we strategically screen carriers and engineered delivery systems to identify candidates with properties aligned with your targeted product profile. To learn how we can expedite the formulation of your biologic, please contact us to discuss your unique project requirements.

References

- Gao H.; et al. Integrated computer-aided formulation design: A case study of andrographolide/ cyclodextrin ternary formulation. Asian J Pharm Sci. 2021, 16(4):494-507.

- Metwally A.A.; Hathout R.M. Computer-assisted drug formulation design: novel approach in drug delivery. Mol Pharm. 2015, 12(8):2800-10.

Related Services

Computer-assisted drug formulation design process (Metwally A.A.; et al. 2015)

Computer-assisted drug formulation design process (Metwally A.A.; et al. 2015)