Antibody Lyophilized Powder Injection Development

InquiryCD Formulation, a pioneering leader in the realm of antibody lyophilized powder injection development services. Our unwavering commitment lies in reshaping the biopharmaceutical landscape through groundbreaking solutions that amplify the stability, convenience, and shelf life of therapeutic antibodies. With avant-garde facilities, a team of seasoned scientists, and an unyielding dedication to unwavering quality, we emerge as your trusted ally in unlocking the boundless potential of antibody lyophilized powder injection preparations.

Characteristics of Antibody Lyophilized Powder for Injection

Freeze-drying, a remarkable process of sublimation that removes water and preserves the structural integrity of antibodies, elevates stability to unprecedented heights while extending the product's shelf life. This transformative technique empowers convenient storage and transportation, all without compromising the therapeutic efficacy of the antibodies.

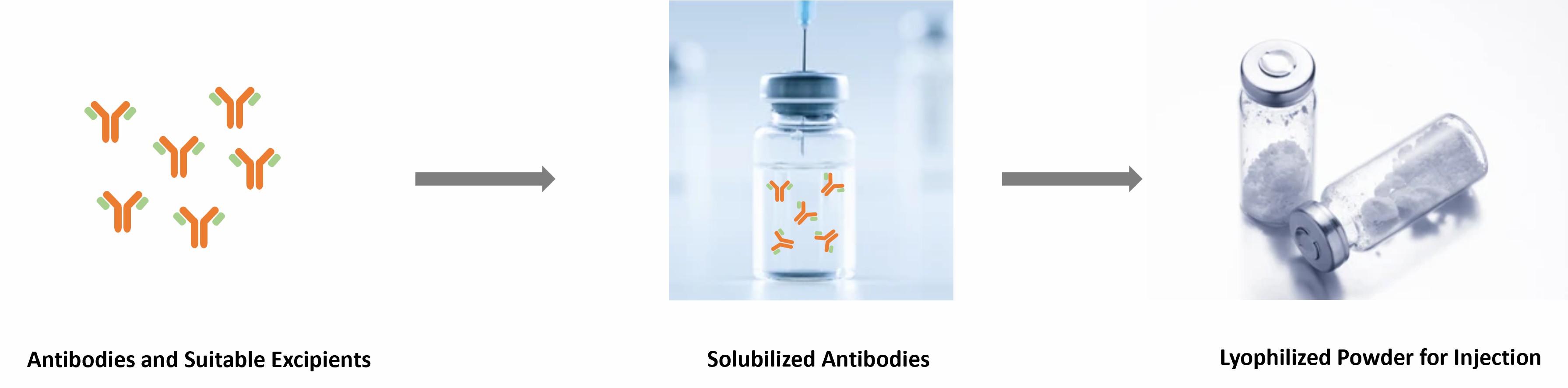

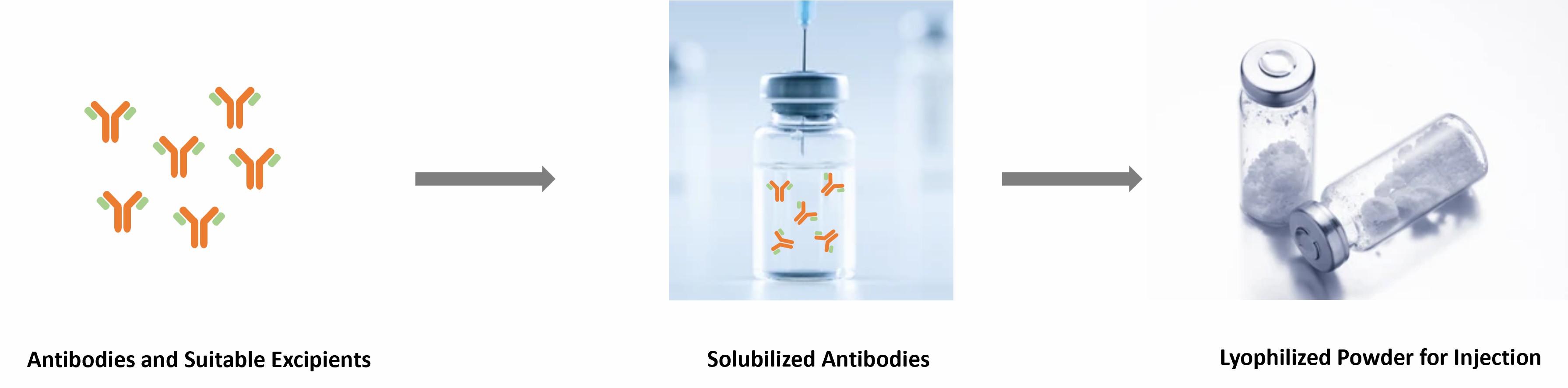

Our Process of Antibody Lyophilized Powder Injection Development

- Consultation and Project Planning

We commence with a profound consultation and a meticulous project planning phase, ensuring an intimate understanding of your unique needs, project goals, and timelines. This enables us to tailor our services with unparalleled effectiveness and precision, aligning our efforts harmoniously with your requirements.

- Selection of Excipients for Antibody Lyophilized Powder Injection Preparations

The selection of excipients for antibody Lyophilized Powder Injection preparations is crucial to maintain stability and optimize the lyophilization process. CD Formulation employs a systematic approach to excipient selection, considering factors such as:

We add cryoprotectants to protect the antibodies during freezing and drying, minimizing protein aggregation and maintaining structural integrity.

In order to maintain the conformation and activity of the antibody, we consider adding appropriate stabilizing excipients based on the nature of the sample to prevent degradation during lyophilization and storage.

Fillers help maintain the physical integrity of lyophilized antibodies and help make the antibody reconstitution process smoother.

Lyophilized powder preparations are non-terminal sterilized products, and there are strict standards for sterility and production process control. We conduct strict sterility tests on packaging materials such as glass bottles, butyl rubber stoppers, and aluminum caps to ensure the quality of the final product.

Our team of experts at CD Formulation specializes in the development of robust and scalable freeze-drying processes for antibody formulations. We employ a systematic approach that includes:

Based on your sample characteristics and needs, we will work closely with you to design and optimize formulations to ensure stability and compatibility with the freeze-drying process, taking into account factors such as protein concentration, buffer composition, and pH.

Our scientists have extensive experience in the biologics field and conduct in-depth research to determine optimal freezing, primary drying and secondary drying conditions to maximize product quality, minimize cycle time and ensure availability and repeatability.

- Quality Control of Antibody Lyophilized Powder for Injection

To ensure the highest standards of product quality, CD Formulation performs comprehensive physical and chemical characterization of lyophilized antibody powders. This includes:

- Moisture Content Determination

To evaluate the stability of the lyophilized powder, we used headspace moisture analysis (HMA) to accurately measure the residual moisture content, using a laser with a wavelength of 1400 nm to pass through the gaseous headspace of the vial containing the lyophilized antibody, based on its absorbance, and using a calibration curve with known water vapor concentration standards to determine the water content in the headspace.

We will conduct sterility testing to verify the rigor of the entire process development process. We use two different media to promote the growth of residual anaerobes, aerobic bacteria, and fungi. Thioglycolate liquid medium (FTM) is commonly used to culture anaerobic bacteria and some aerobic bacteria, and soybean trypsin broth (SCDM) is commonly used to culture fungi and aerobic bacteria. Samples were incubated at 32.5°C and 22.5°C for 14 days respectively before assay. Turbidity in the culture medium indicates possible microbial growth and must be investigated. We can also provide you with sterility testing services.

Advantages of our Antibody Lyophilized Powder Injection Development Services

Our team of scientists and industry experts possesses extensive knowledge and experience in antibody formulation development, ensuring the highest level of scientific expertise and innovation.

- Customization and Flexibility

We offer flexible solutions tailored to your specific needs, accommodating a wide range of therapeutic antibodies and formulation goals.

- Collaboration and Communication

We believe in building collaborative partnerships with our clients. We foster open communication, transparency, and a client-centric approach, working closely with you to achieve your project objectives.

CD Formulation's comprehensive services encompass formulation design, process development, and analytical characterization, ensuring that your antibody lyophilized powder injection preparations meet the highest standards of quality and performance. We understand that each project is unique, and our team of experts collaborates closely with you to tailor our services to your specific needs. Whether you require optimized formulation composition, precise freeze-drying processes, or comprehensive analytical data, we are here to exceed your expectations. For inquiries about our antibody lyophilized powder injection preparation development services and pricing information, please don't hesitate to contact us!

Related Services