Antibody Drug Process Development and Scale-up

InquiryGetting antibody therapies from lab to market requires meticulous process development and seamless scale-up. CD Formulation not only has a profound biomedical background and professional technical knowledge, but also has rich practical experience. We can develop personalized solutions based on customers' specific needs and the market environment to ensure that the development of antibody drugs can be completed smoothly.

What Can We Do for Antibody Drug Process Development?

CD Formulation has a wealth of knowledge and a global perspective to understand the key elements and processes of antibody development, and can help customers develop and optimize antibody drug processes and shorten the commercialization cycle of antibody drugs. At the same time, we have large-volume sample storage systems, preparation systems, filling systems and transportation systems, which can meet the needs of customers throughout the entire process of antibody drug development.

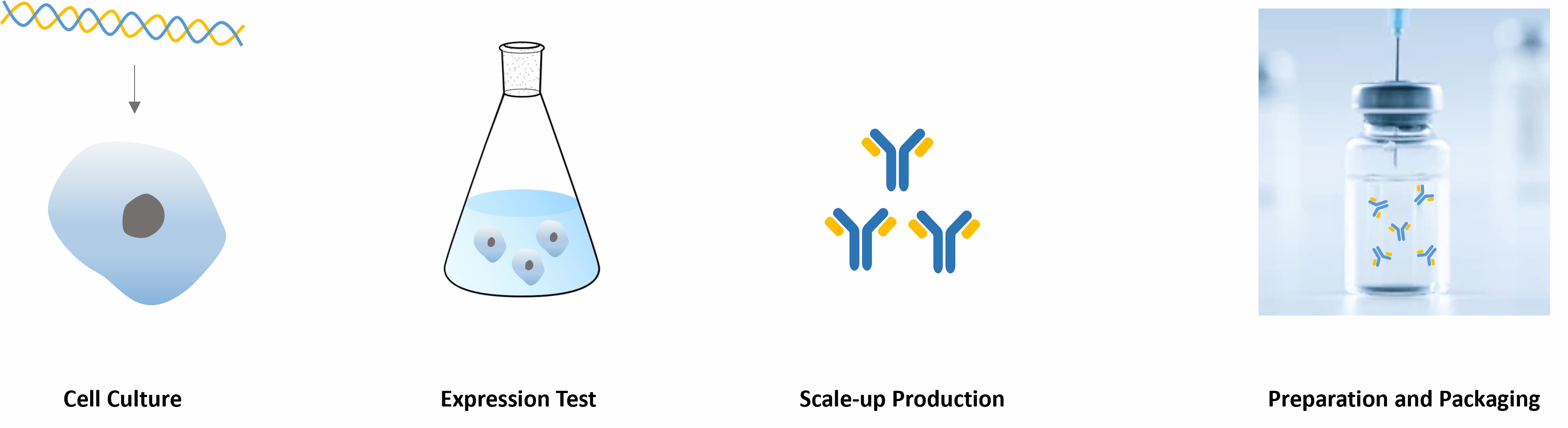

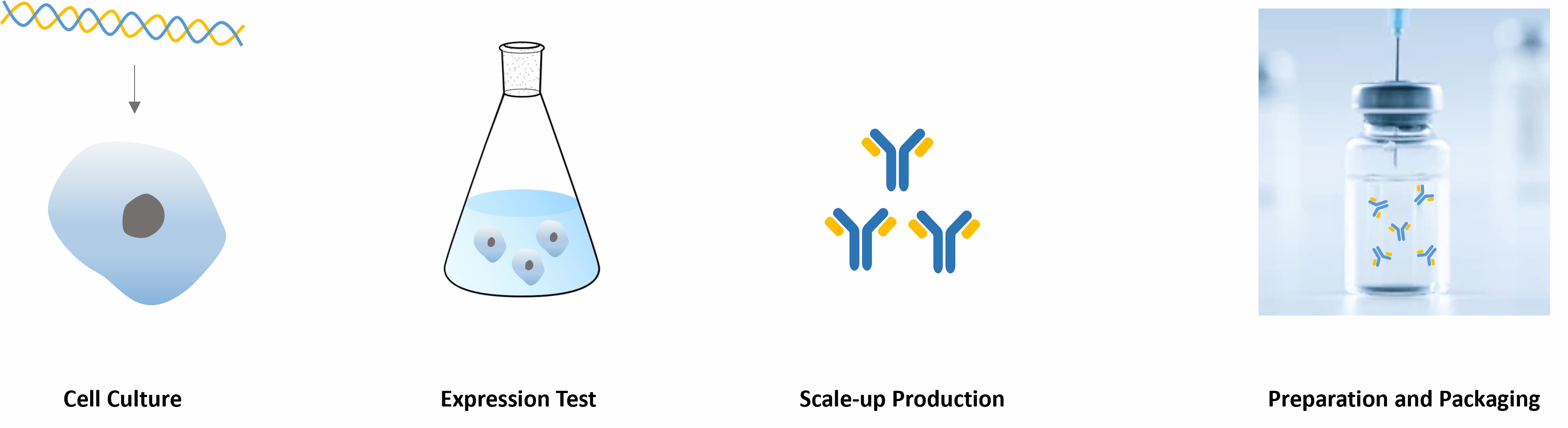

This usually involves the generation of stable mammalian cell lines. CD Formulation's cell library is very comprehensive. We can help customers transform cells to express and secrete antibodies, and we can also expand the culture of cells to achieve mass production of antibodies.

We focus on optimizing bioprocess parameters for large-scale antibody production. It includes defining the culture medium composition, cell growth conditions, and bioreactor parameters such as temperature, pH, dissolved oxygen, and agitation. Fed-batch or perfusion culture strategies may be employed to achieve high antibody yields.

We can carry out the construction of antibody mass production lines, equipment selection, production parameter adjustment, process verification, etc. At the same time, based on customer needs, we will optimize production efficiency, cost control, environmental impact and other factors.

Developing the optimal formulation is crucial for antibody drugs to reach their full therapeutic potential. At CD Formulation, our experts can create conventional antibody formulations like injections and lyophilized powders. We can also incorporate antibodies into biocompatible nanocarriers like polymer nanoparticles or hydrogels. These advanced platforms allow targeted and sustained antibody release.

In order to facilitate transportation and ensure the stability and safety of antibodies, we can select the most appropriate packaging materials for antibody drugs, and continuously optimize and fill process parameters, including the dosage of the can, ambient temperature and humidity, etc. Throughout the entire process, we will strictly control the sterility of the environment.

Throughout the entire antibody development process, we implement strict quality control measures to ensure the identity, purity, potency and safety of our antibodies. We can also help customers with quality control of antibody mass production, using analytical techniques such as mass spectrometry and potency assays to assess quality attributes and confirm compliance with regulatory requirements.

Advantages of Our Antibody Drug Process Development and Scale-up Services

- One stop solution

- Professional team

- Rich project experience

- Scalable process development

- Timely updated technologies, processes and methods

- Professional consultation and after-sales service

With a focus on optimizing antibody drug processes and scale-up, CD Formulation ensures enhanced yields, improved product quality, and accelerated time to market. We possess the technical expertise to efficiently scale up from small-scale to large-scale production, ensuring scalability, flexibility, and cost optimization. With access to our experienced scientists and technical support, you can navigate challenges, streamline processes, and achieve efficient problem-solving. If you are looking for related services, then please do not hesitate to contact us!

Related Services